Machine and method for cleaning evaporation tank

The technology of evaporation tank and cleaning machine is applied in the field of cleaning operation of the heat exchange tube of the evaporation tank, which can solve the problems of high labor intensity and poor safety, and achieve the effects of low labor intensity, safe use and reduction of complex actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

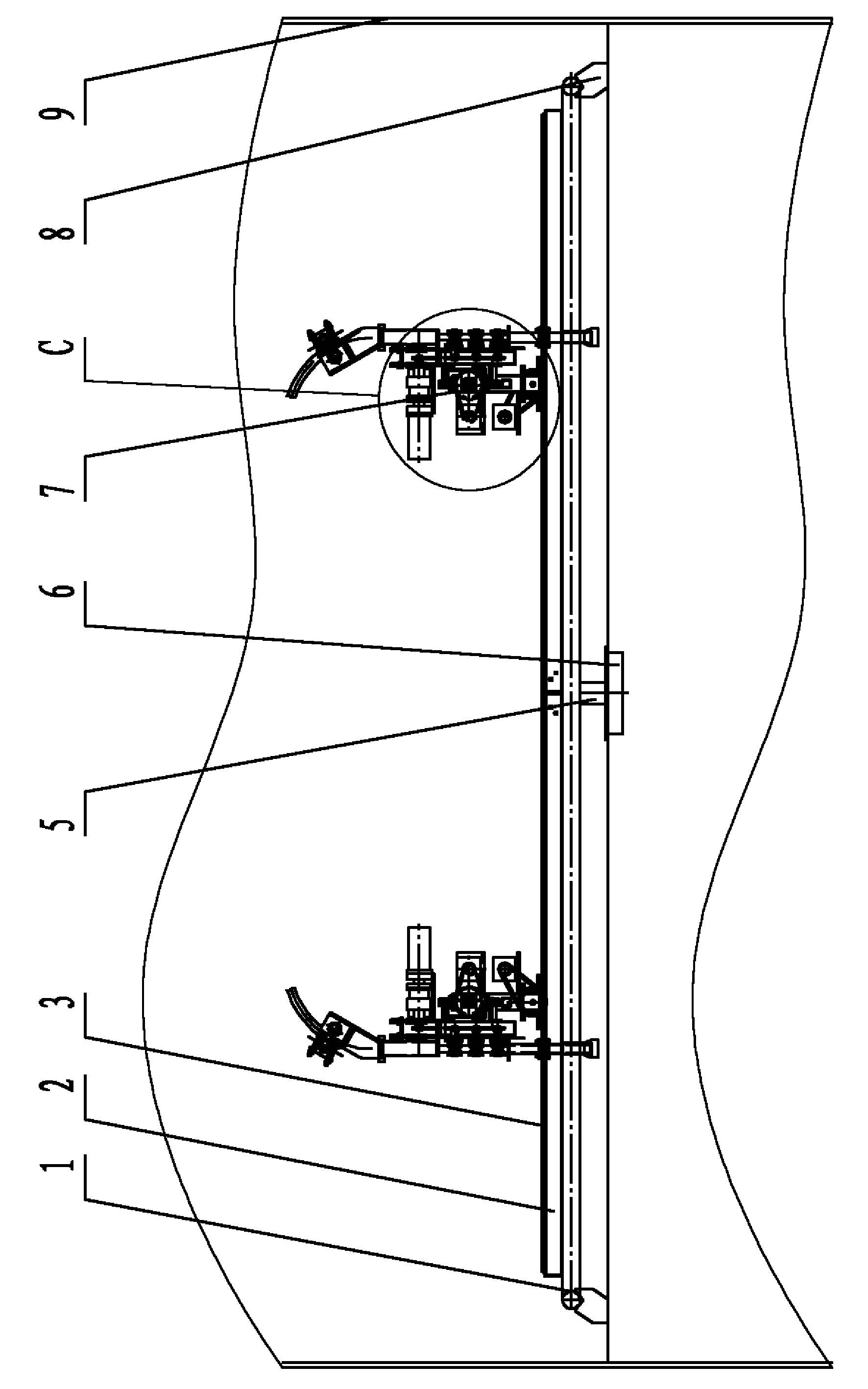

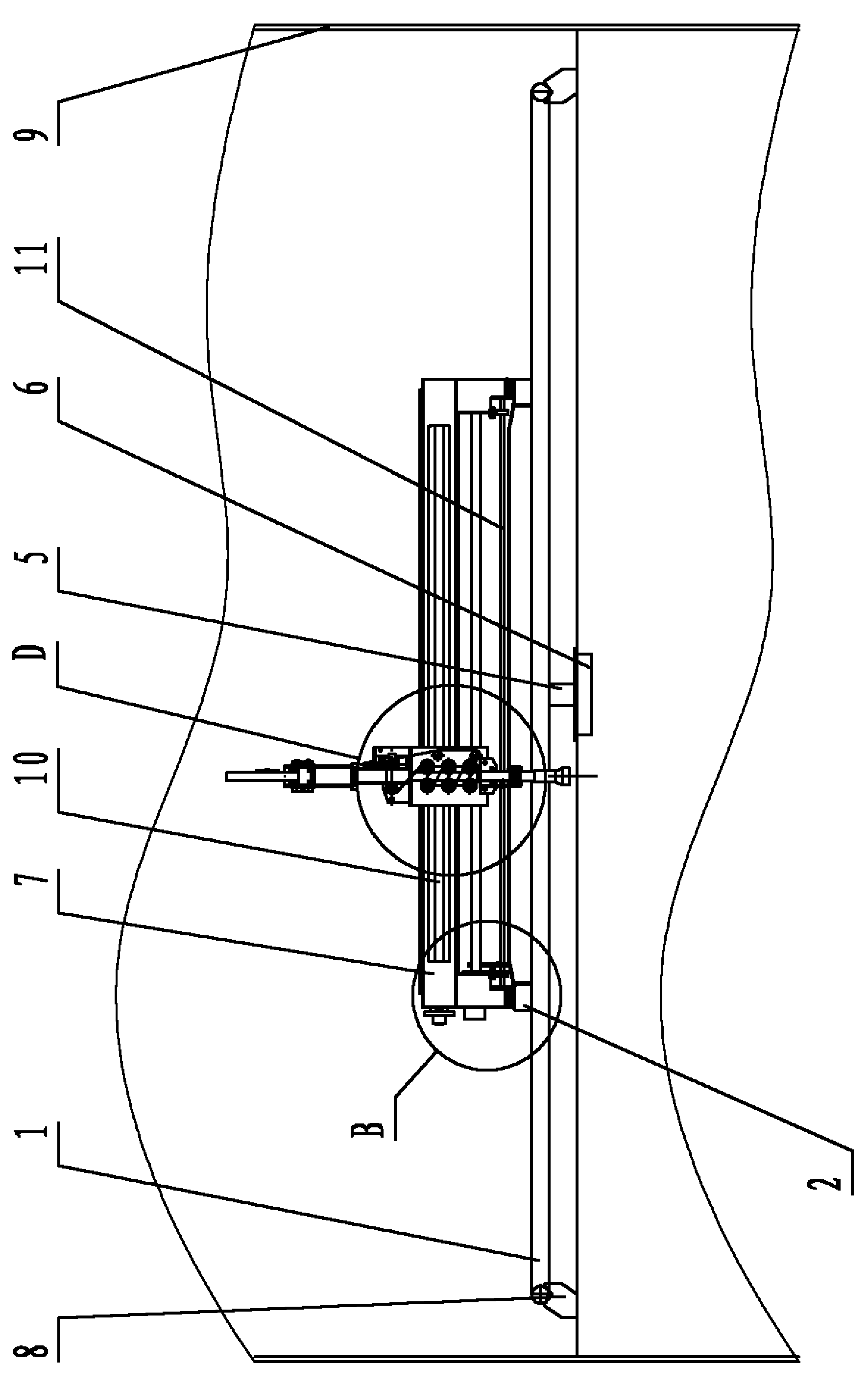

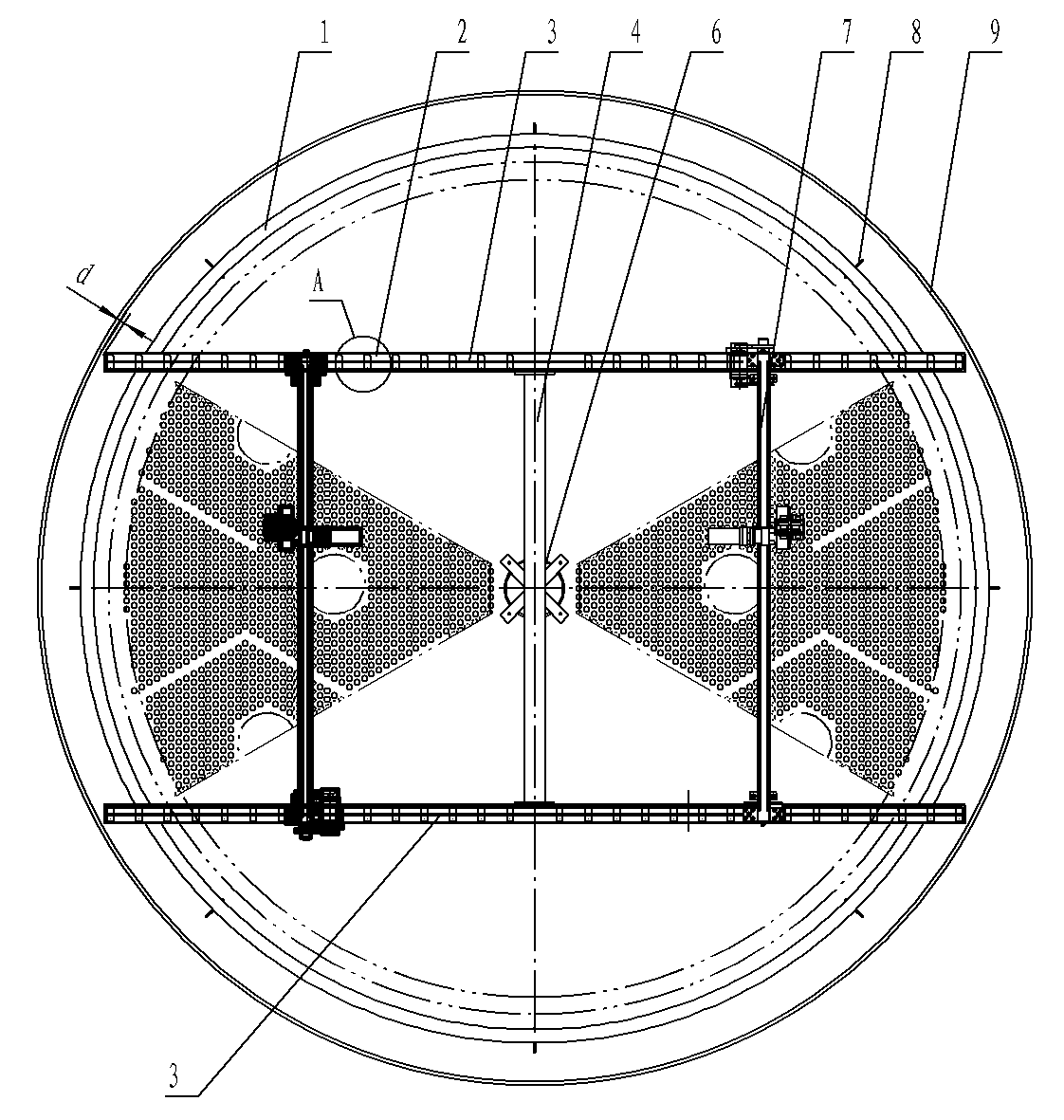

[0027] Below in conjunction with accompanying drawing example the present invention is described in further detail:

[0028] figure 1 , figure 2 and image 3 Shown is the model BM-5 manufactured by the applicant, and the product name is the overall structure of the evaporation tank cleaning machine in the evaporation tank of the computer-controlled automatic tank cleaning machine. The frame of the machine has a four-section arc-shaped circle An annular pipe 1 composed of pipe connections, on which an "H"-shaped rack top beam formed by four longitudinal beams 2 and a crossbeam 4 is connected by bolts, and every two butt joint longitudinal beams 2 The top surface is respectively equipped with a longitudinal track that a track slide rail 3 constitutes, and these two track slide rails 3 are parallel to each other. The center of the lower end of the beam 4 is welded with a positioning shaft 5 protruding downward. The positioning shaft 5 is inserted into the shaft hole of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com