Layer-stranded optical cable

A layer-twisted, optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of low optical fiber concentration and small number of optical fibers, and achieve the effect of high optical fiber concentration, increasing optical fiber number, and improving tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

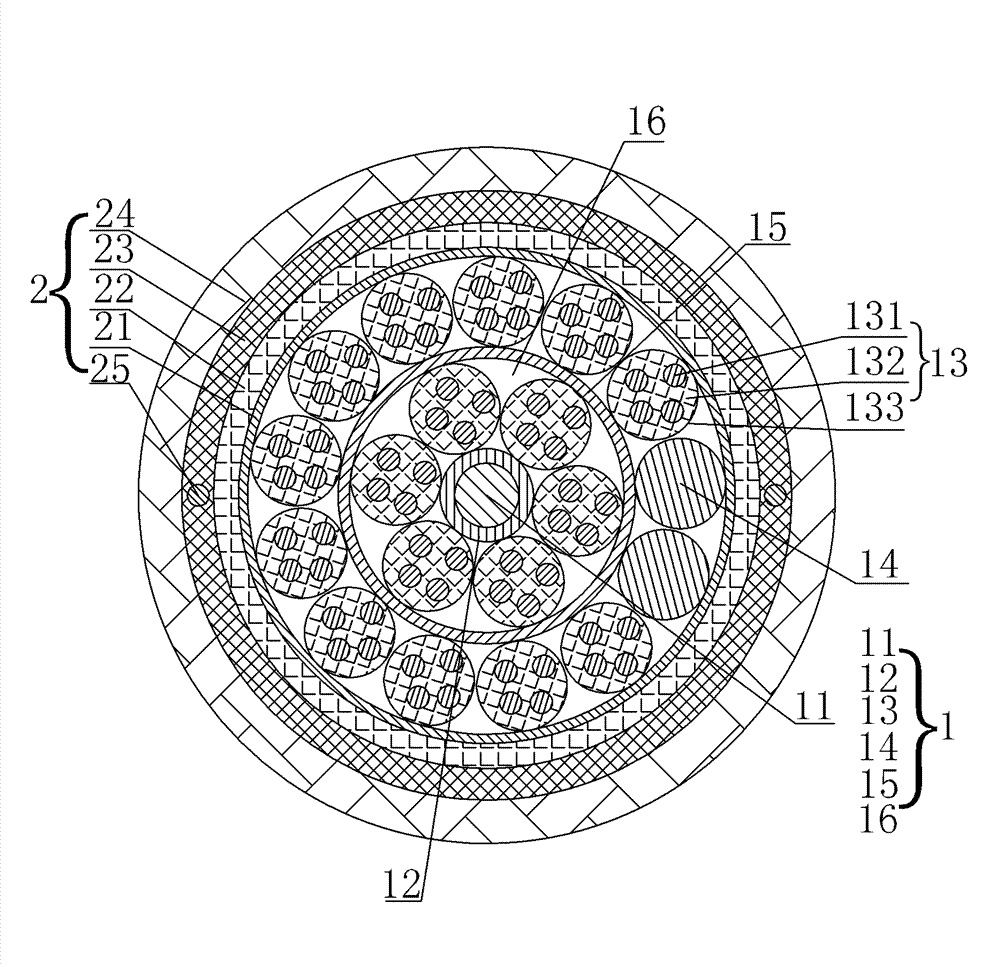

[0012] Such as figure 1 As shown, the stranded optical cable of this layer is composed of a cable core 1 and a sheath 2 wrapped outside the cable core 1 .

[0013] From the inside to the outside, the cable core 1 is successively composed of a reinforcement 11 with a cushion layer 12, six optical fiber units 13 twisted and arranged on the outer periphery of the cushion layer 12, a wrapping layer 14, and a twisted arrangement on the outer periphery of the wrapping layer 14 11. Each optical fiber unit 13 and two filling ropes 16, the water barrier 17 is filled between the wrapping layer 14 and the optical fiber unit 13, each of the optical fiber units 13 is composed of four optical fibers 131, coated on four optical fibers 131 and the fiber paste 132 filled between the loose tube 133 and the optical fiber 131.

[0014] The sheath 2 is composed of a water blocking tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com