Fuel cell module

A technology of fuel cells and fuel cell units, applied in the direction of fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of reducing power density and achieve the effects of reducing contact resistance, improving efficiency, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

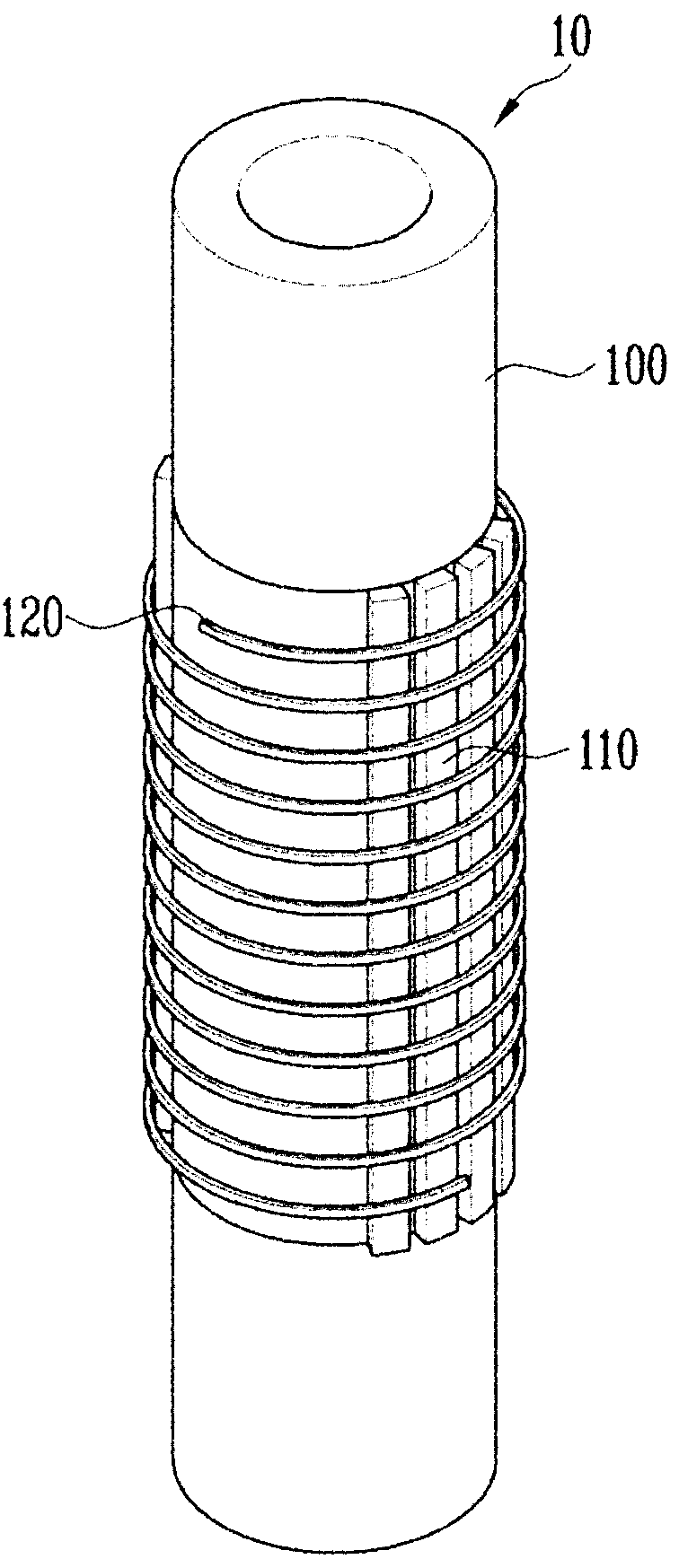

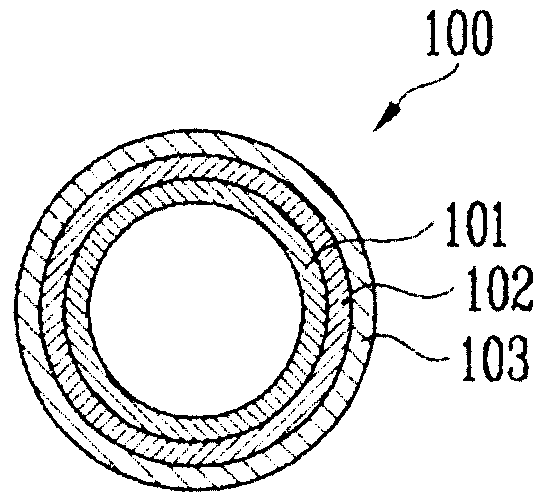

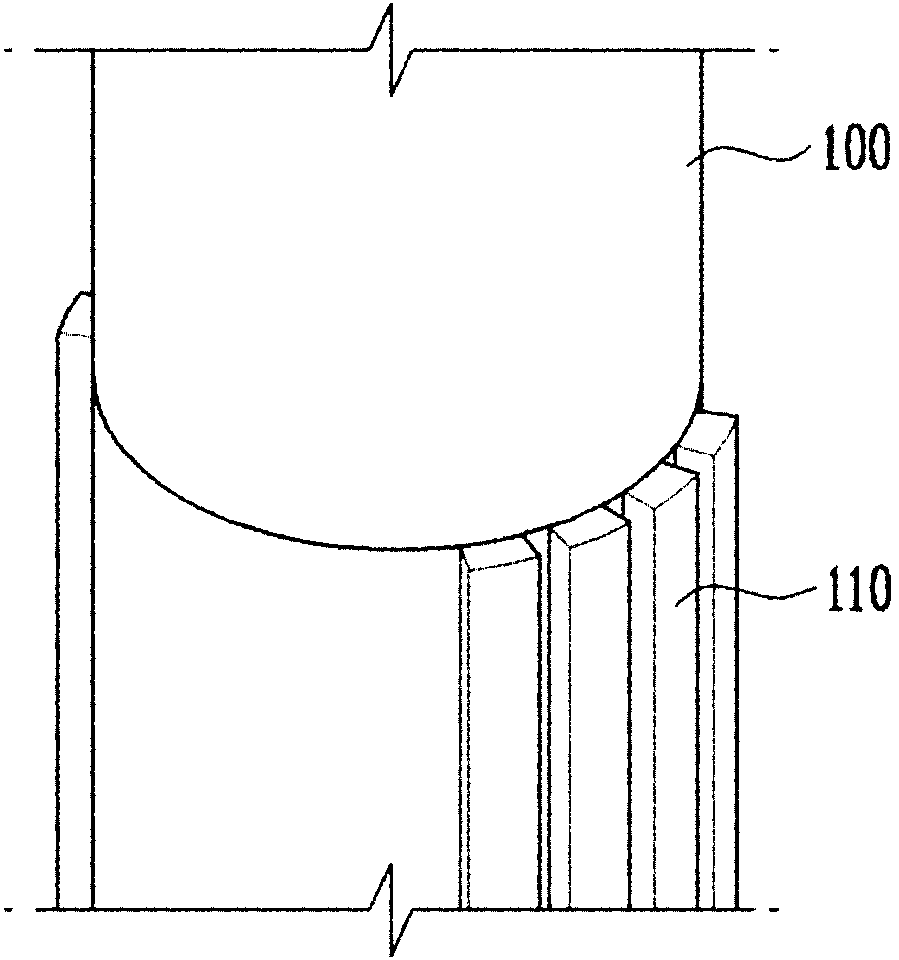

[0035] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. If not specifically defined or elucidated, 'upper', 'lower', 'left' and 'right' are used herein to describe directions based on the drawings. Furthermore, like reference numerals designate like elements in all embodiments.

[0036] A typical fuel cell consists of a fuel processor (reformer and reactor) that reforms and provides fuel, and a fuel cell module. A fuel cell assembly includes a stack of fuel cells that utilize electrochemical reactions or processes to convert chemical energy into electrical and thermal energy. That is, in one embodiment, the fuel cell assembly includes: a fuel cell stack (fuel cell stack); a pipe system through which fuel, oxides, cooling water, and effluent flow; wires, The electricity generated by the stack is conducted through the wires; the components of the stack are controlled or monitored; and the components that handle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com