Assembling device and assembling method of FPD component

A technology of assembling device and assembling method, applied in the direction of identification device, instrument, etc., can solve the problem of not improving production efficiency, and achieve the effect of preventing thermal deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

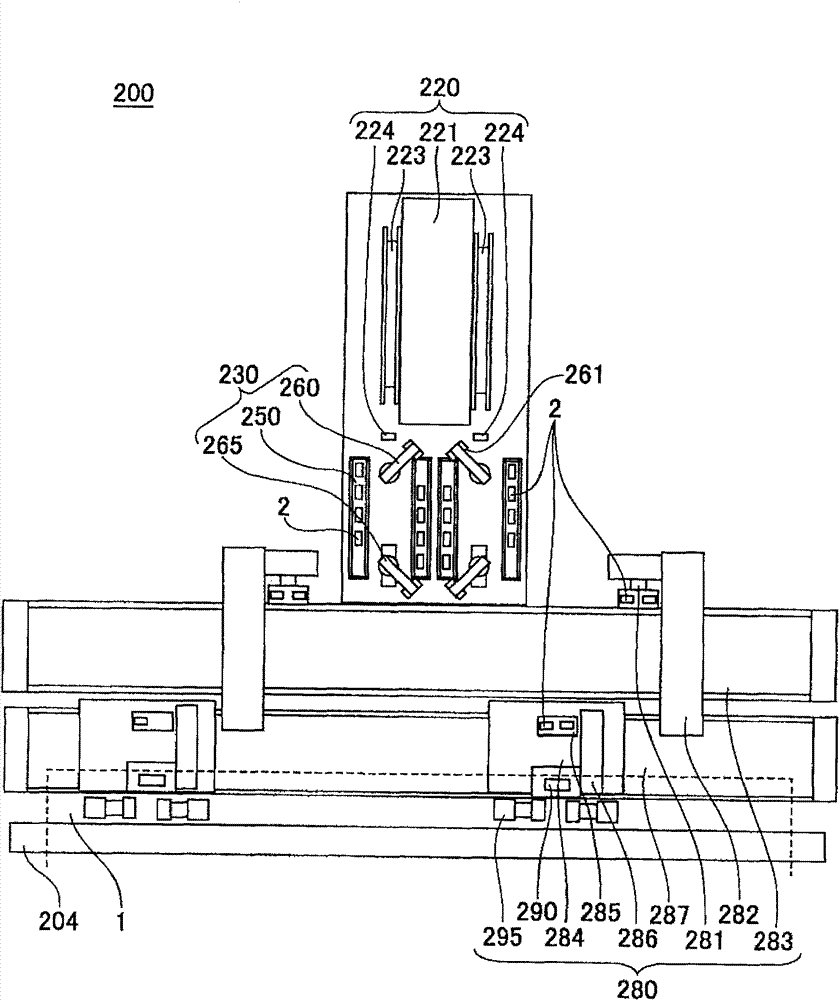

[0107] Next, refer to Figure 9 A second embodiment of the FPD module assembly device of the present invention will be described.

[0108] Figure 9 It is a front view showing the cooling state of the heat shield plate of the final crimping part according to the second embodiment of the present invention.

[0109] The second embodiment of the present invention has the same structure as the FPD module assembly line 10 of the first embodiment. The difference between the second embodiment of the present invention and the FPD module assembly line 10 of the first embodiment is that scrolls are provided in the TAB-side thermal insulation mechanism and the substrate-side thermal insulation mechanism.

[0110] Such as Figure 9 As shown, the TAB-side thermal insulation mechanism 350A and the substrate-side thermal insulation mechanism 350B of the second embodiment of the present invention have a scroll 344 on the rear side of the nozzle 342 in order to enhance cooling of the therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com