P type microcrystalline silicon carbon film material for PI flexible substrate solar cell and preparation

A technology for solar cells and flexible substrates, applied in metal material coating processes, circuits, photovoltaic power generation, etc., can solve the problems of low conductivity, structural mismatch, low activation energy and light absorption, and achieve the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

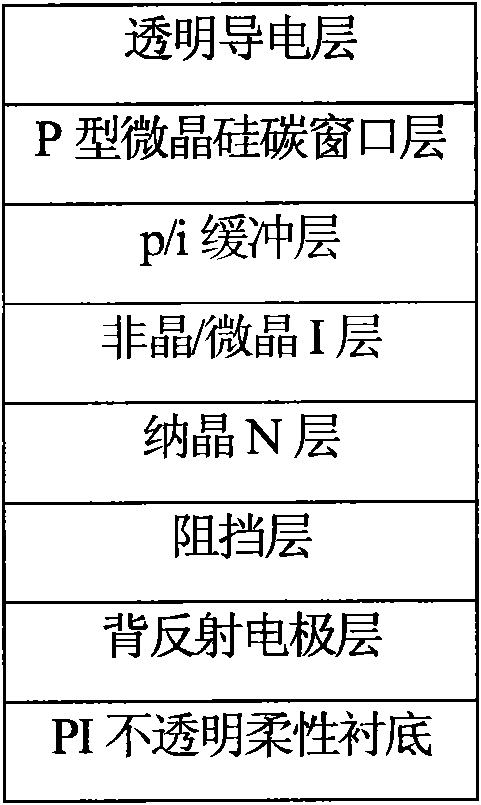

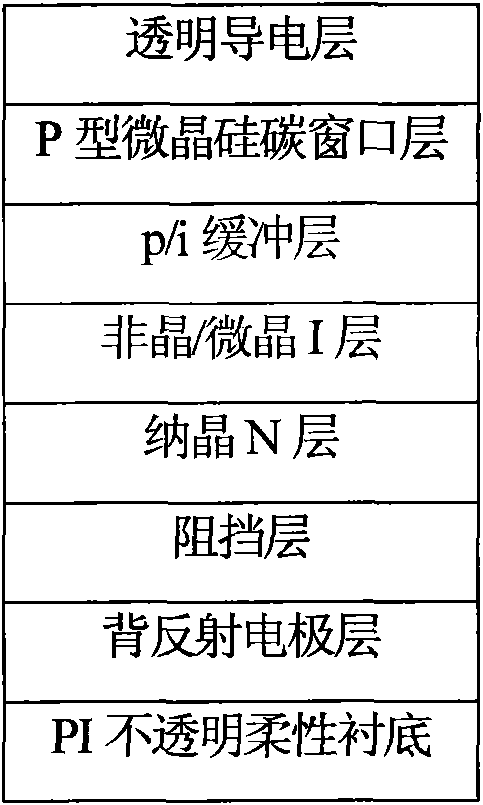

Method used

Image

Examples

Embodiment 1

[0039] On Eagle2000 glass substrate, adopt silane, hydrogen, borane, methane as reactive gas, by PECVD method, radio frequency power source frequency is 13.56MHz, according to the preparation method that thin film solar cell uses P-type window layer of the present invention to comprise Step, select the deposition parameters, where the reaction parameters are as follows:

[0040] Substrate temperature: 150°C,

[0041] Power density: 350mW / cm2,

[0042] Reaction pressure: 200Pa,

[0043] Silane concentration: 0.55%,

[0044] Borane doping concentration: 0.5%,

[0045] Methane doping concentration: 7.5%.

[0046] The prepared P-type microcrystalline silicon carbon material has a conductivity of 0.15 S / cm, a band gap greater than 2.0 eV, and a crystallization rate of 45.4% under the premise of a thickness of 30 nm.

Embodiment 2

[0048] The substrate temperature is fixed at 150°C and the power density is 350mW / cm 2 .The silane concentration is 0.55%, the borane doping concentration is 0.5%, under the condition of keeping the total gas flow constant, the carbon-silicon ratio (CH 4 / SiH 4 ) varies between 7.5% and 13.75%, and the dark state conductivity σ can be obtained by adjusting the doping amount of methane d 0.15S / cm and optical bandgap E g The P-type microcrystalline silicon carbon material above 2.0eV, combined with the optimized carbon-doped p / i buffer layer for PI opaque flexible substrate thin film battery, obtained an open circuit voltage of 0.87V and a short circuit current density of 11.98mA / cm 2 , the fill factor is 54%, and the photoelectric conversion efficiency is 5.67%.

[0049] In summary, the P-type microcrystalline silicon carbon combines the advantages of the wide band gap of the P-type amorphous silicon carbon and the high conductivity and low light absorption of the P-type mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com