Method for producing dendrobium officinale tissue culture mycorrhizal seedlings

A Dendrobium officinale and production method technology, applied in the field of tissue cultured mycorrhizal seedling production of Dendrobium officinale, can solve the problems of lack of mycorrhizal fungi, low survival rate, easy to infect miscellaneous bacteria, etc., achieve more new shoots, tillering, and large growth , the effect of plant internode expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

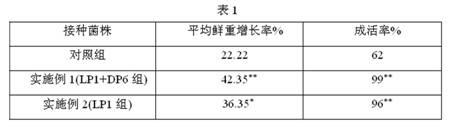

Examples

Embodiment 1

[0021] (1) Culture of mycorrhizal fungi

[0022] In this example, the mycorrhizal fungus LP1 was used to activate once the strains in inclined test tubes stored at low temperature, and then transferred to PDA plates, and cultured at a constant temperature of 25°C for 12 days. The edge is perforated into a bacterial sheet, and the solid medium is inserted into a small piece;

[0023] The fungal strain culture adopts solid culture, and the solid medium material of mycorrhizal fungus is mixed with cottonseed hulls and broad-leaved tree sawdust in a weight ratio of 1:1, and the amount of water added is 170 wt% of the raw material; The g medium was connected with 2 bacterial slices (Φ=8 mm); the fungus was cultured in the dark with an Erlenmeyer flask, and when most or all of the hyphae were covered with the medium, it was taken out to obtain solid mycorrhizal fungi;

[0024] (2) Culture of mycorrhizal bacteria

[0025]Prepare nitrogen-free medium: glucose 10 g / L, NaCl 0.2 g / L, K...

Embodiment 2

[0035] The basic operation of this embodiment is the same as that of Embodiment 1, the difference is:

[0036] 1. The bacterial strain LP1 fungal strain used in this embodiment does not adopt the DP6 bacterial strain.

[0037] 2. Mycorrhizal fungi adopt liquid culture medium. Preparation of medium: prepared with water, glucose 20 g / L, KH 2 PO 4 20 g / L, MgSO 4 1.5 g / L, vitamin B 1 10 mg / L, natural product: wheat bran 30 g / L (boiled juice), medium pH=6.0. After autoclaving, the above-mentioned fungi were inserted, and 2 bacterial slices (Φ=8 mm) were inserted into each 100 mL of medium. The fungus was cultivated in the dark with shaking and aeration in the Erlenmeyer flask with a filling capacity of 50% and a rotational speed of 100 rpm, and was cultured at 25°C for 25 days and harvested. After the culture is finished, the culture product is crushed with a homogenizer to obtain liquid mycorrhizal fungi.

[0038] During the production of Dendrobium candidum tissue-cultu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com