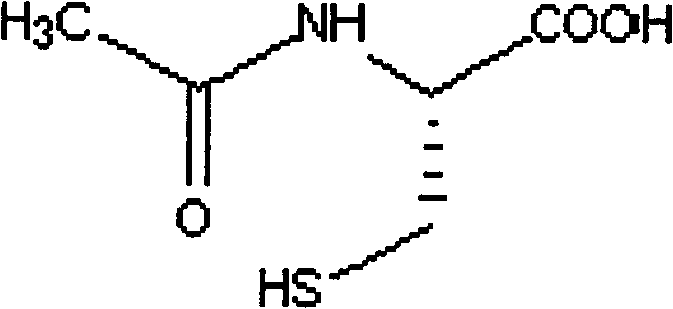

Acetylcysteine granule and preparation technology thereof

A technology of acetylcysteine and granules, applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, bulk delivery, etc., can solve DNA damage, instability to moisture, DNA single-strand breakage And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: 10000 bags in batch

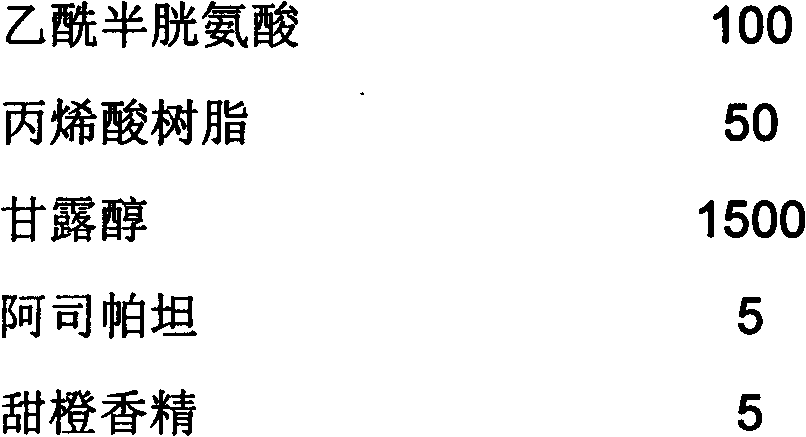

[0042] prescription:

[0043]

[0044] Preparation method: (1) uncoat acetylcysteine with acrylic resin; the particle size of the acetylcysteine coating powder is controlled at 150um; (2) use water as a binder, granulate mannitol, Drying, the particle size of the mannitol dry granules is controlled at 75 μm to 300 μm, and the drying weight loss of the granules is controlled to be ≤0.5%; (3) Mix the acetylcysteine coating powder, the mannitol dry granules, aspartame, and sweet orange essence evenly, Filling, finished product inspection, packaging.

Embodiment 2

[0045] Embodiment 2: 10000 bags in batch

[0046] prescription:

[0047]

[0048] Preparation method: (1) uncoat acetylcysteine with acrylic resin; the particle size of the acetylcysteine coating powder is controlled at 150um; (2) use water as a binder, granulate mannitol, Drying, the particle size of the mannitol dry granules is controlled at 75 μm to 300 μm, and the weight loss of the granules is controlled to be ≤0.5%; (3) Mix the acetylcysteine coating powder, the mannitol dry granules, aspartame, and sweet orange essence evenly , Filling, finished product inspection, packaging.

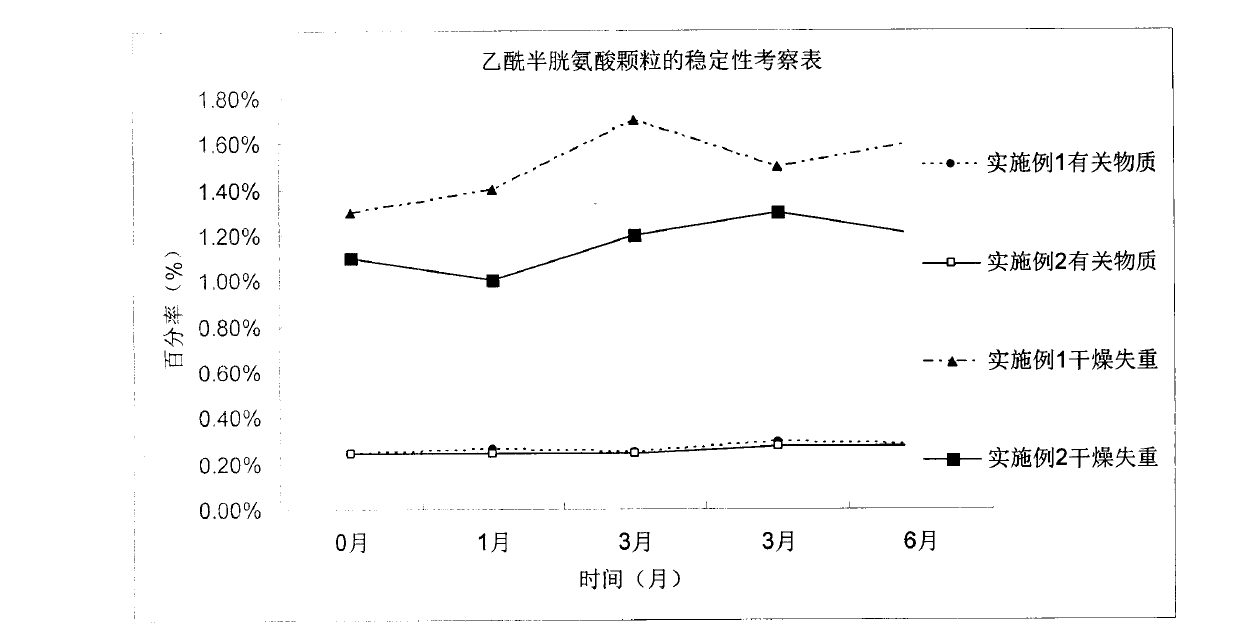

[0049] The stability of acetylcysteine particles was investigated. Take the acetylcysteine granules under the items of Example 1 and Example 2, remove the outer packaging, place them for 6 months at a temperature of 40°C ± 2°C, and a relative humidity of 75% ± 5%. Sampling and analysis at 1 month, 2 months, 3 months, and 6 months to determine the loss on drying and related substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com