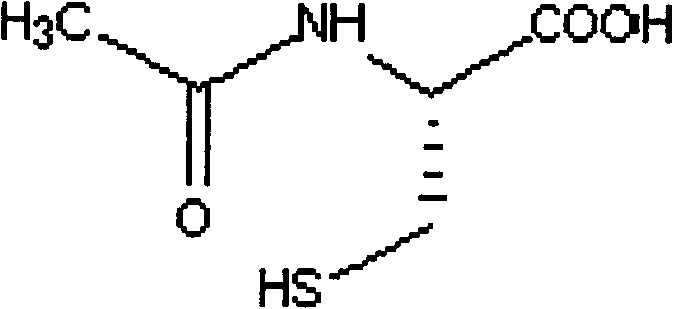

Acetylcysteine granule and preparation technology thereof

A technology of acetylcysteine and its preparation process, which is applied in the field of acetylcysteine particles and its preparation process, and can solve problems such as humidity instability, DNA single-strand breaks, and DNA damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Batch 10,000 bags

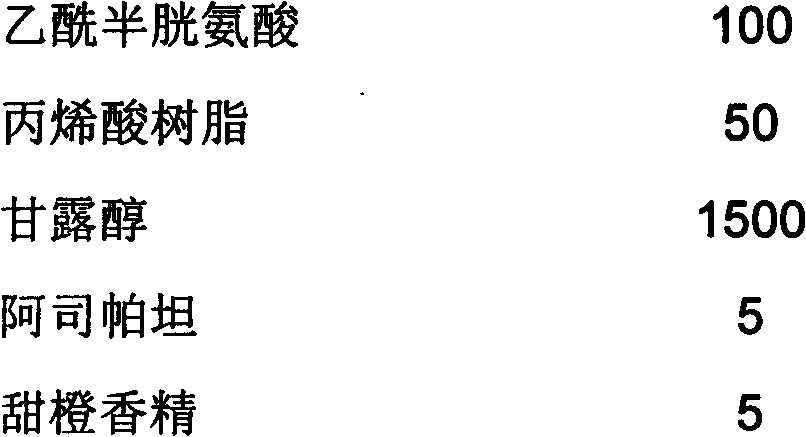

[0042] prescription:

[0043]

[0044] Preparation method: (1) Acrylic cysteine is used for powder coating with acrylic resin; the particle size of the acetylcysteine coating powder is controlled at 150um; (2) Water is used as a binder, and mannitol is granulated, Drying, the particle size of mannitol dry particles is controlled within 75μm~300μm, and the weight loss on drying of the particles is controlled ≤0.5%; (3) Mix acetylcysteine coating powder, mannitol dry particles, aspartame, and orange flavor evenly, Filling, finished product inspection, packaging.

Embodiment 2

[0045] Example 2: Batch 10,000 bags

[0046] prescription:

[0047]

[0048] Preparation method: (1) Acrylic cysteine is used for powder coating with acrylic resin; the particle size of the acetylcysteine coating powder is controlled at 150um; (2) Water is used as a binder, and mannitol is granulated, Drying, the size of the mannitol dry particles is controlled within 75μm~300μm, and the weight loss on drying of the particles is controlled ≤0.5%; (3) Mix the acetylcysteine coating powder, mannitol dry particles, aspartame, and orange flavor evenly , Filling, finished product inspection and packaging.

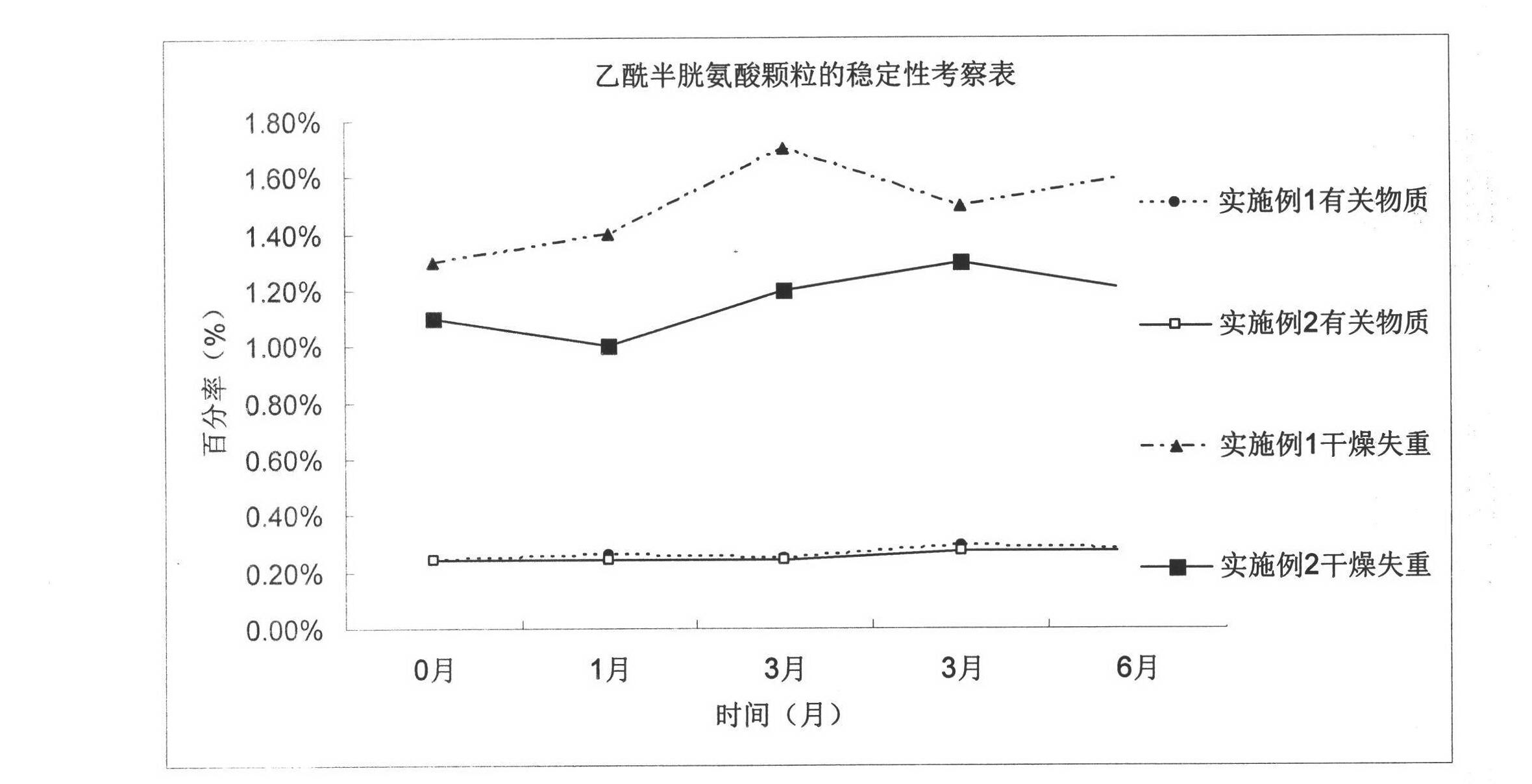

[0049] The stability of acetylcysteine particles was investigated. Take the acetylcysteine granules under Example 1 and Example 2, remove the outer packaging, and place them for 6 months at a temperature of 40℃±2℃ and a relative humidity of 75%±5%. Monthly, 2 months, 3 months, 6 months sampling and analysis to determine the loss on drying and related substances of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com