Polypropylene wood plastic environment-friendly pencil and manufacturing method thereof

A polypropylene and wood-plastic technology, applied in non-moving pencils, printing, writing utensils, etc., can solve problems such as unusable pencils, reduce equipment costs and labor costs, solve forest resource problems, and achieve high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

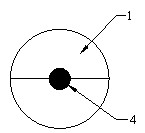

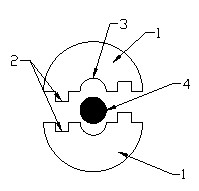

[0041] refer to figure 1 and figure 2 , the cross-section of the pen holder is circular, where figure 2 A male and female groove structure 2 is arranged in it.

Embodiment 2

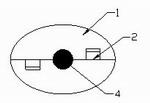

[0043] refer to image 3 , the cross-section of the pen holder is elliptical and the splicing surface is provided with a male and female groove structure 2 for positioning and matching.

Embodiment 3

[0045] refer to Figure 4 , the cross-section of the pen holder is hexagonal and the splicing surface is provided with a positioning fit male and female groove structure 2; refer to Figure 5 , the cross-section of the pen holder is triangular and the three corners of the circumference of the pen holder are rounded to increase the comfort of the hand.

[0046] The splicing surfaces of the above-mentioned half sides are provided with male and female groove structures 2 for positioning and matching.

[0047] A semicircular refill mounting groove 3 is provided in the middle of the splicing surface of the above-mentioned half sides.

[0048] The above two half sides are made by wood-plastic extrusion molding, compression molding or injection molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com