Arch ring lining trolley for additionally building open cut tunnel on electrified railway business line and construction method of arch ring lining trolley

A technology for electrified railways and lining trolleys, which is applied in wellbore lining, tunnel lining, earth-moving drilling, etc., can solve the problems of long construction period, inability to meet, poor safety, etc., and achieves the effect of good safety and reduced operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

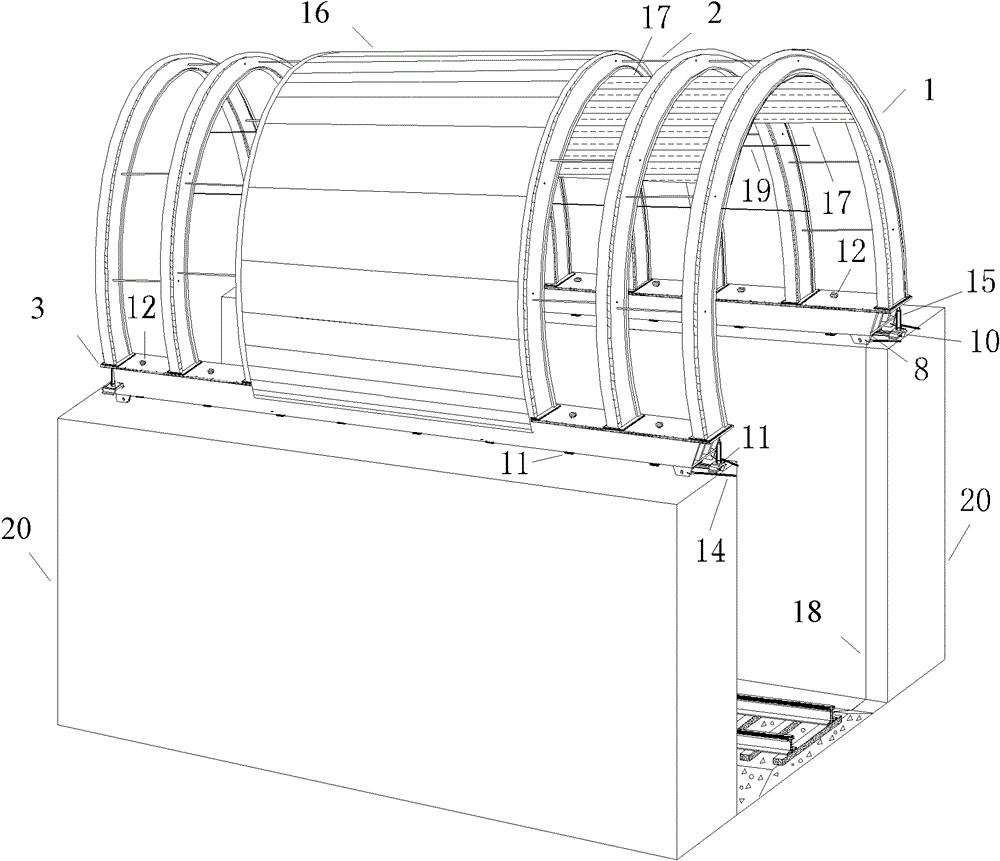

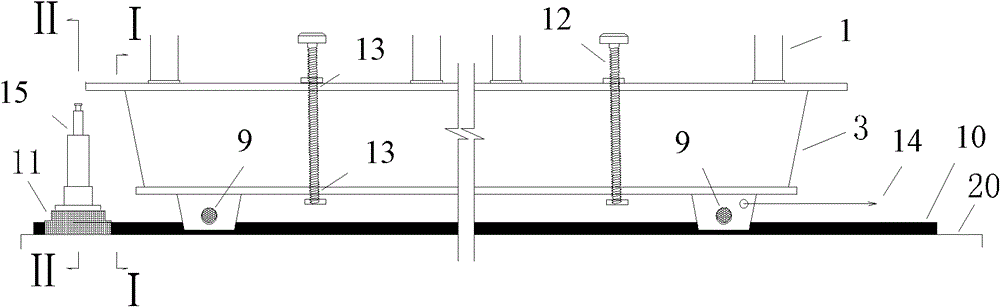

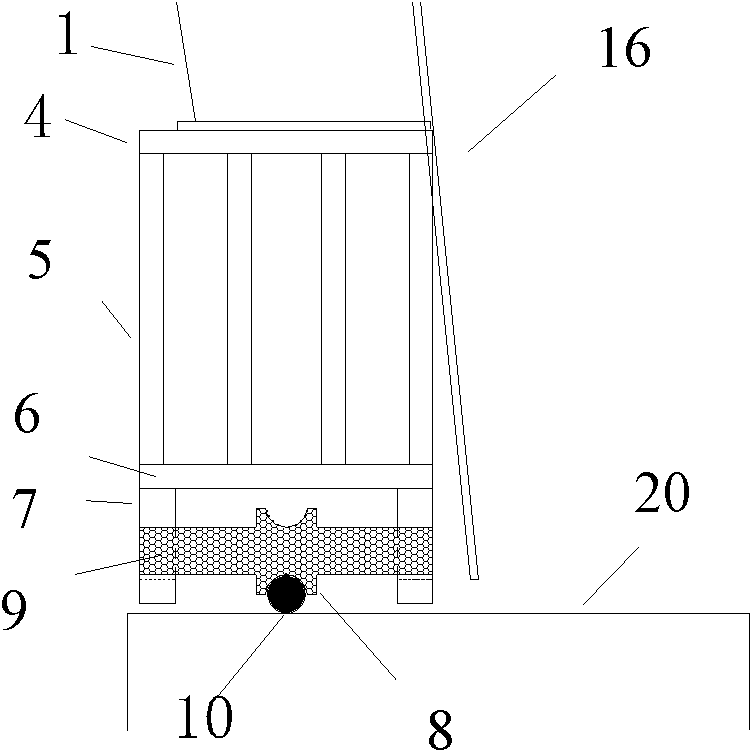

[0029] The following is a detailed description of the arch ring lining trolley and construction method for adding open tunnels to electrified railway business lines provided by the present invention in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as Figure 1-Figure 3As shown, the electrified railway business line provided by the present invention increases the construction of open-hole arch ring lining trolley including trolley, running gear, lifting device and anti-electricity device; The root joist 3 and a plurality of steel templates 16 are formed; the traveling device is composed of two slide rails 10 and four rollers 8; the lifting device is composed of four jacks 15, a plurality of screw rods 12 and a plurality of backing plates 11; The device is composed of multiple anti-electric boards 17 and two grounding wires 18; the two slide rails 10 are fixed on the top surfaces of the two side walls 20 along the length direction of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com