Package part dropping tester

A technology of drop test and package, which is applied in the field of equipment for drop test of package, can solve the problems of low degree of automation, low applicability, high risk of operation, etc., and achieve high degree of automation, strong detection reliability and safety factor high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

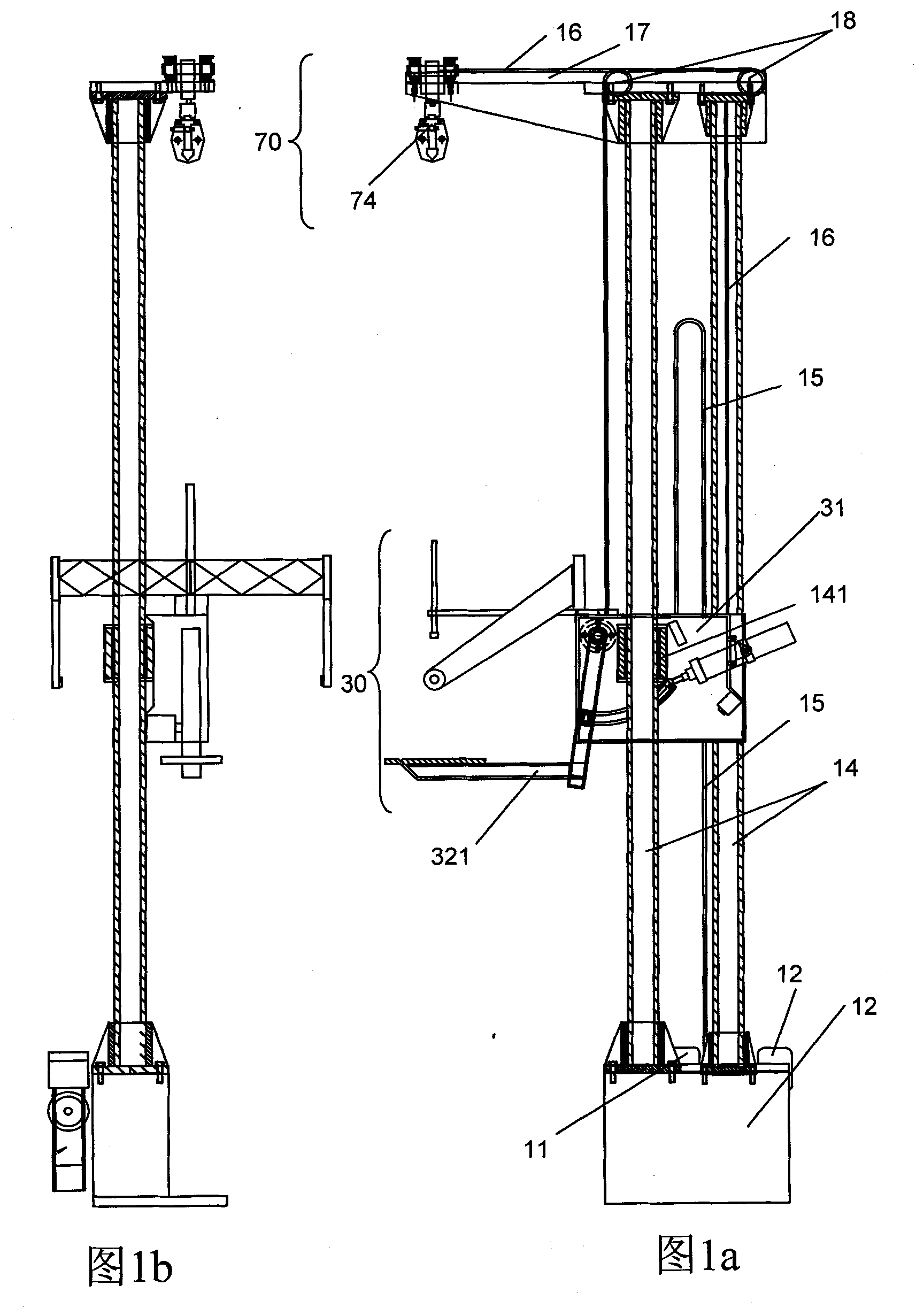

[0049] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

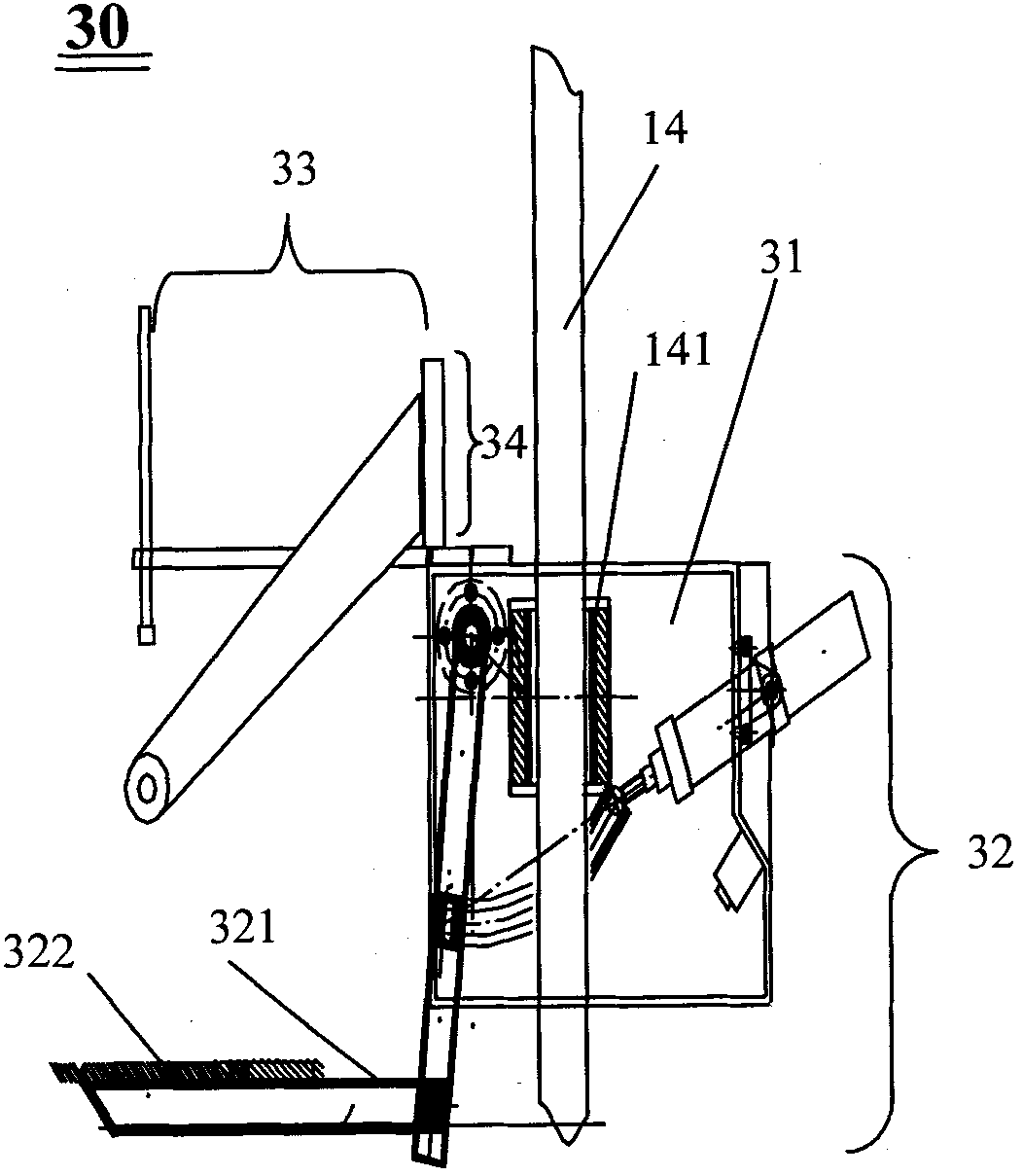

[0050] The package drop test machine of the present invention not only has the structure of a driving drop test machine, but also has the structure of a pull plate drop test machine. The packaging drop tester of the present invention is mainly composed of a lifting device, a pull plate drop device and a driving drop device installed on the lifting device, and an electrical control device for controlling the operation of the lifting device, the pull plate drop device and the driving drop device.

[0051] The structures of these devices will be described in detail below.

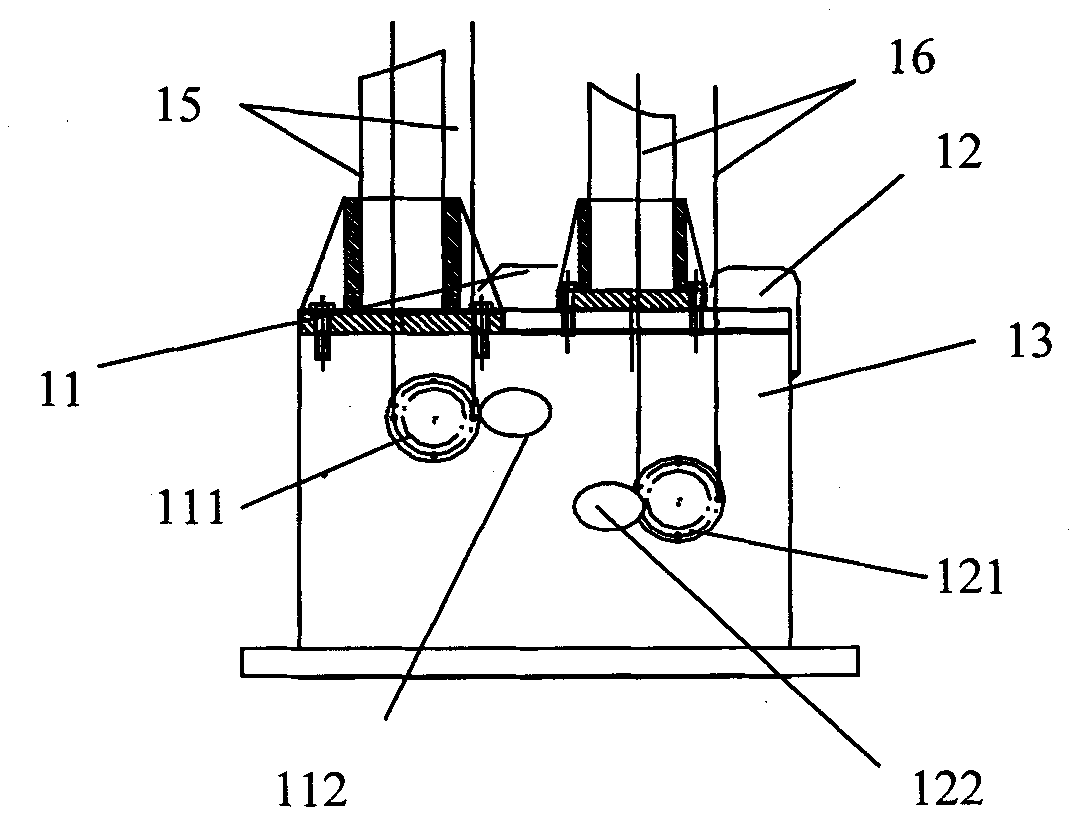

[0052] see Figure 1a , Figure 1b , figure 2 ,in Figure 1b for Figure 1a side view.

[0053] The first part is the lifting device 10, which includes: the pull plate drop servo motor 11 installed on the main frame (not shown), the driving drop servo motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com