Air duct system of reliability test bed for drive line of high-speed motor train unit

A technology for high-speed EMUs and drive trains, applied in the testing of machine gears/transmission mechanisms, etc., can solve the problems of large transmitted torque and affect the service life of the test bench, and achieve the effects of preventing excessive waste, reducing noise, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with accompanying drawing:

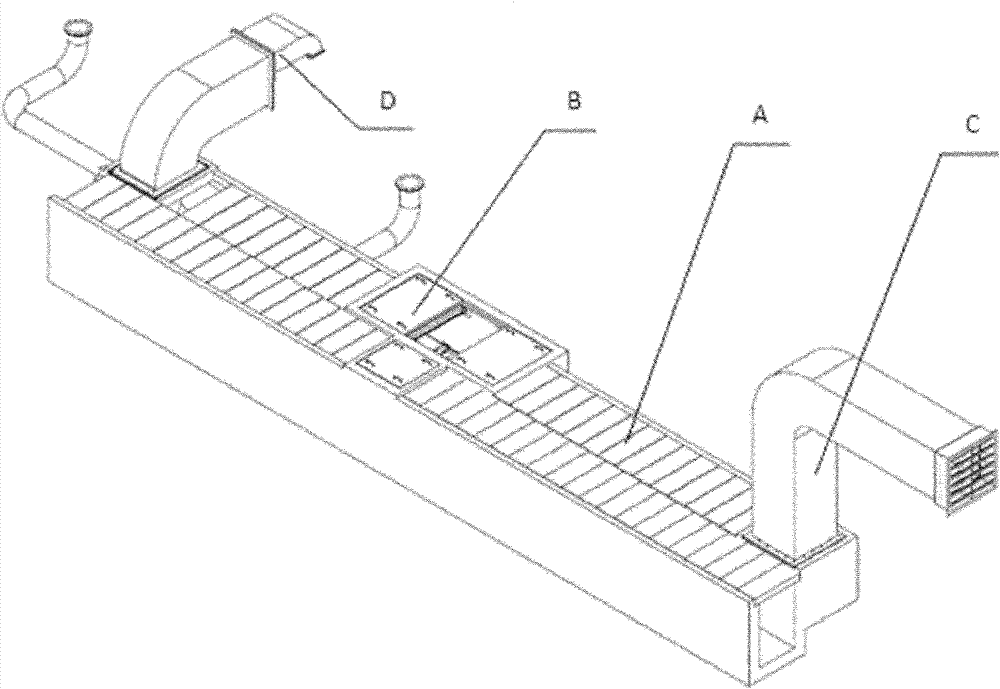

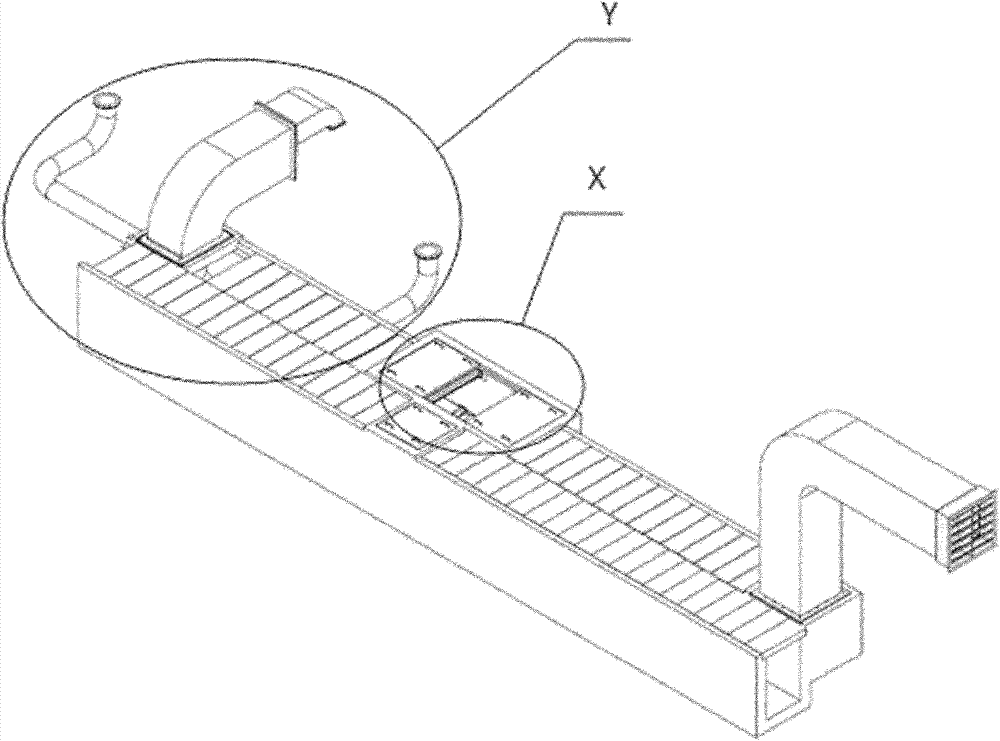

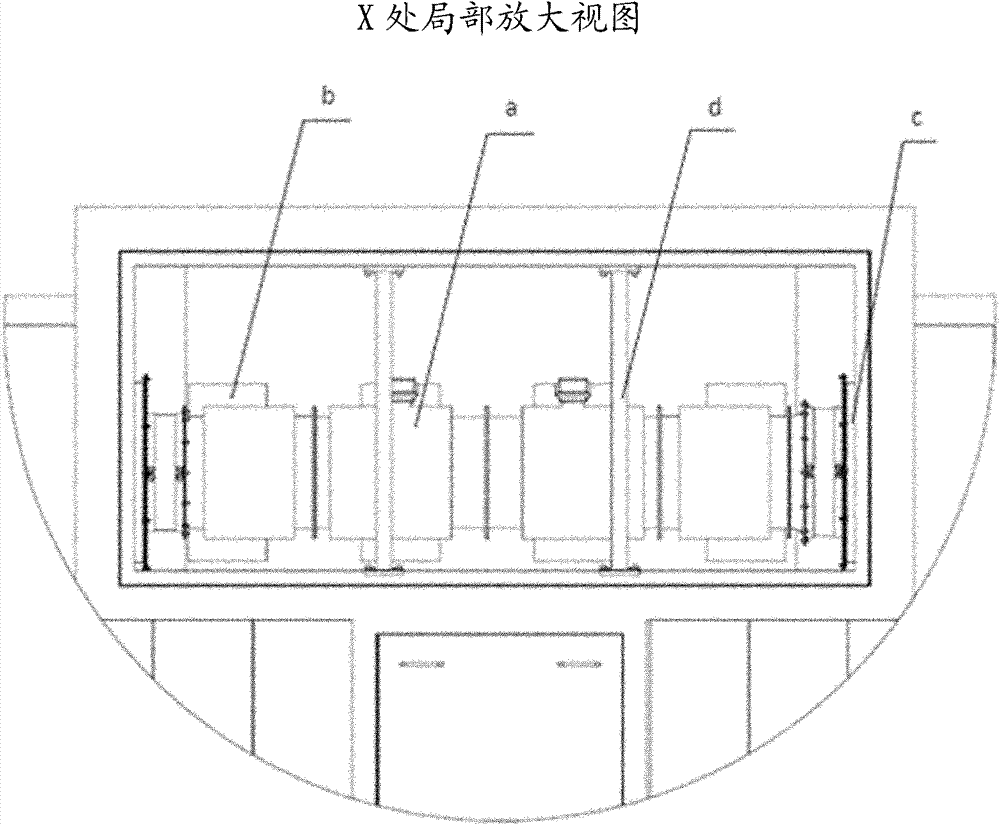

[0042] The object of the present invention is to provide an air duct system for a reliability test bench of a high-speed EMU drive train, so as to meet the need for timely heat dissipation when the reliability test bench of a high-speed EMU drive train generates a large amount of heat energy. The air duct system of the high-speed EMU power train reliability test bench adopts a reasonable structural design of the heat dissipation channel, and adopts the form of an air-cooled channel with one inlet and multiple outlets to quickly, effectively and targetedly dissipate heat from the test bench equipment, ensuring The concentration of air-cooling energy not only reduces the waste of energy, but also realizes the timely cooling of the test bench equipment.

[0043] refer to figure 1 , the air duct system of the high-speed EMU drive train reliability test bench is composed of an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com