Signal generator and excess revolution test system for turboshaft engine of manual operation type twin-engine helicopter

A signal generator and engine technology, applied in engine testing, machine/structural component testing, instruments, etc., can solve the problem that technical details cannot be obtained from public channels, and achieve the effect of making up for technical gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

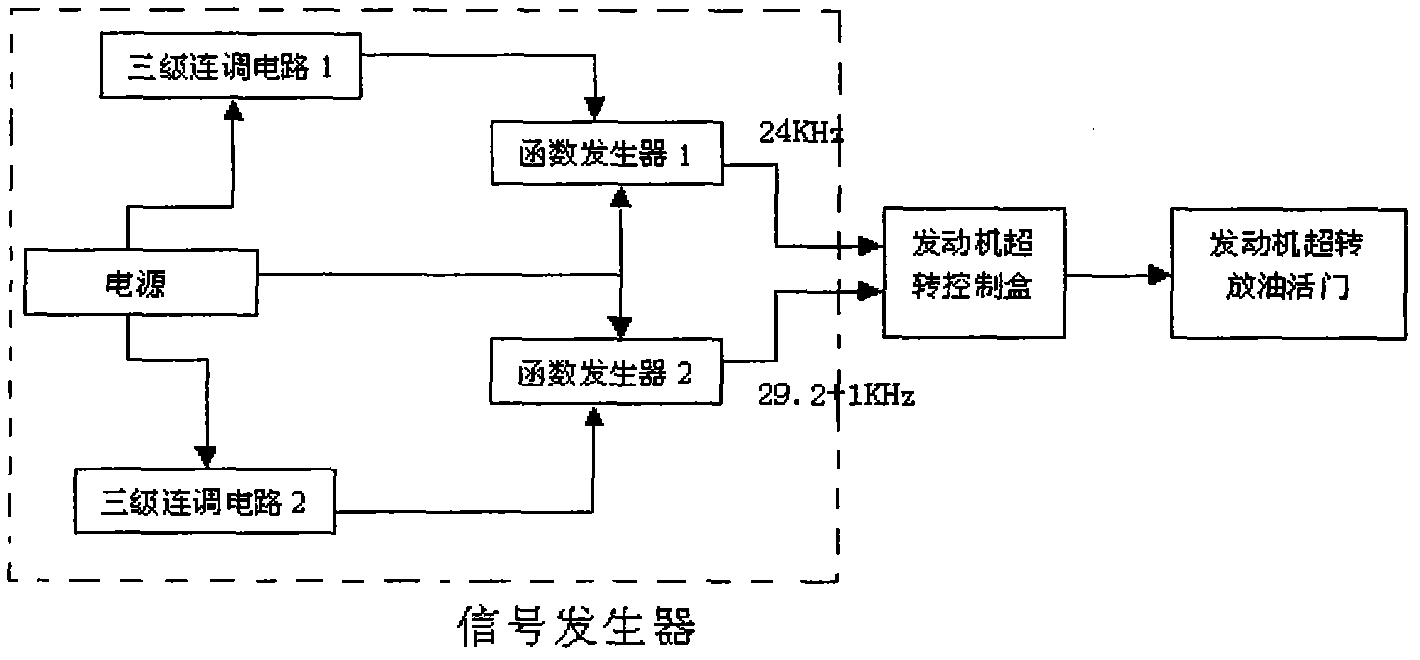

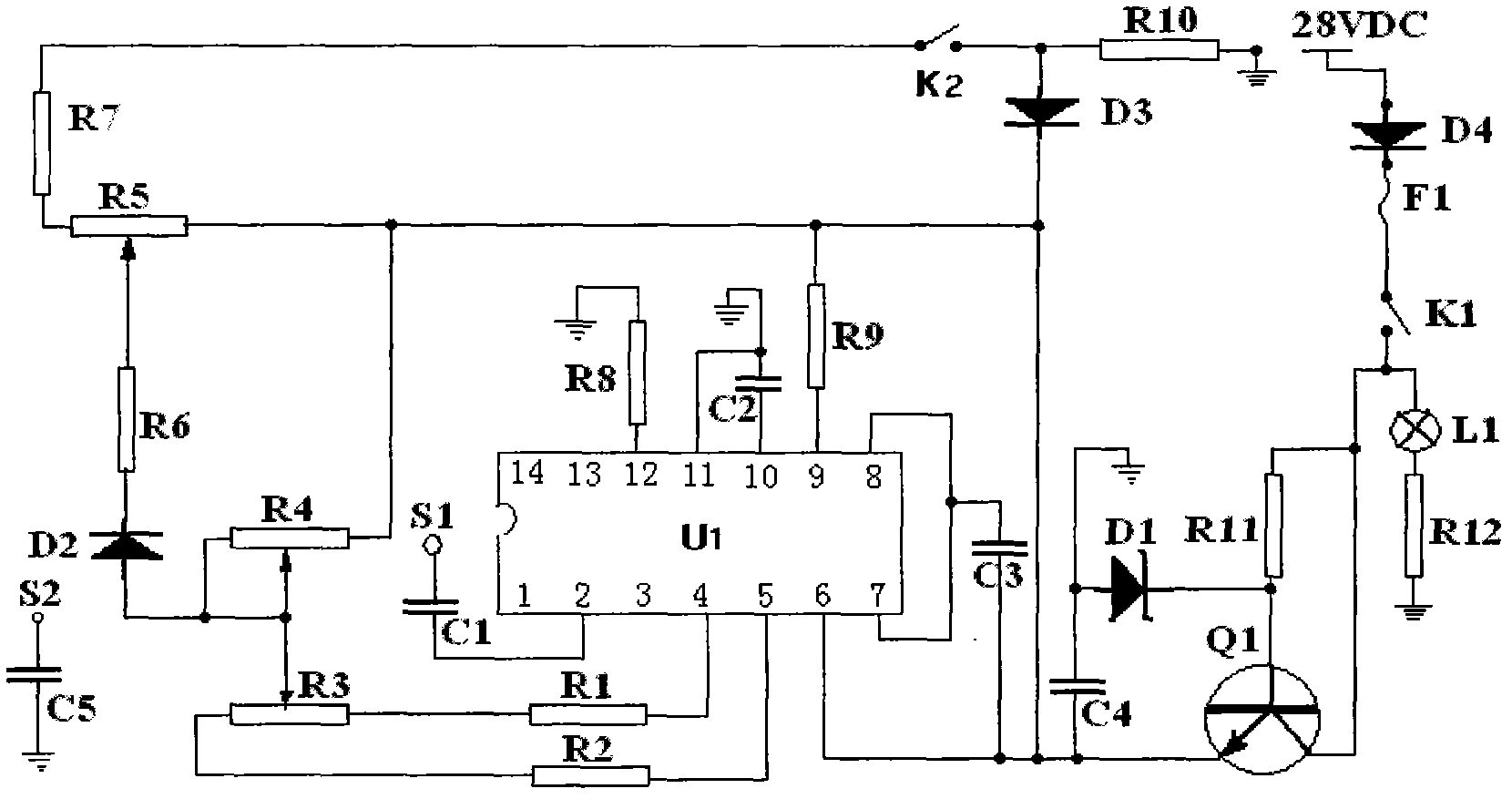

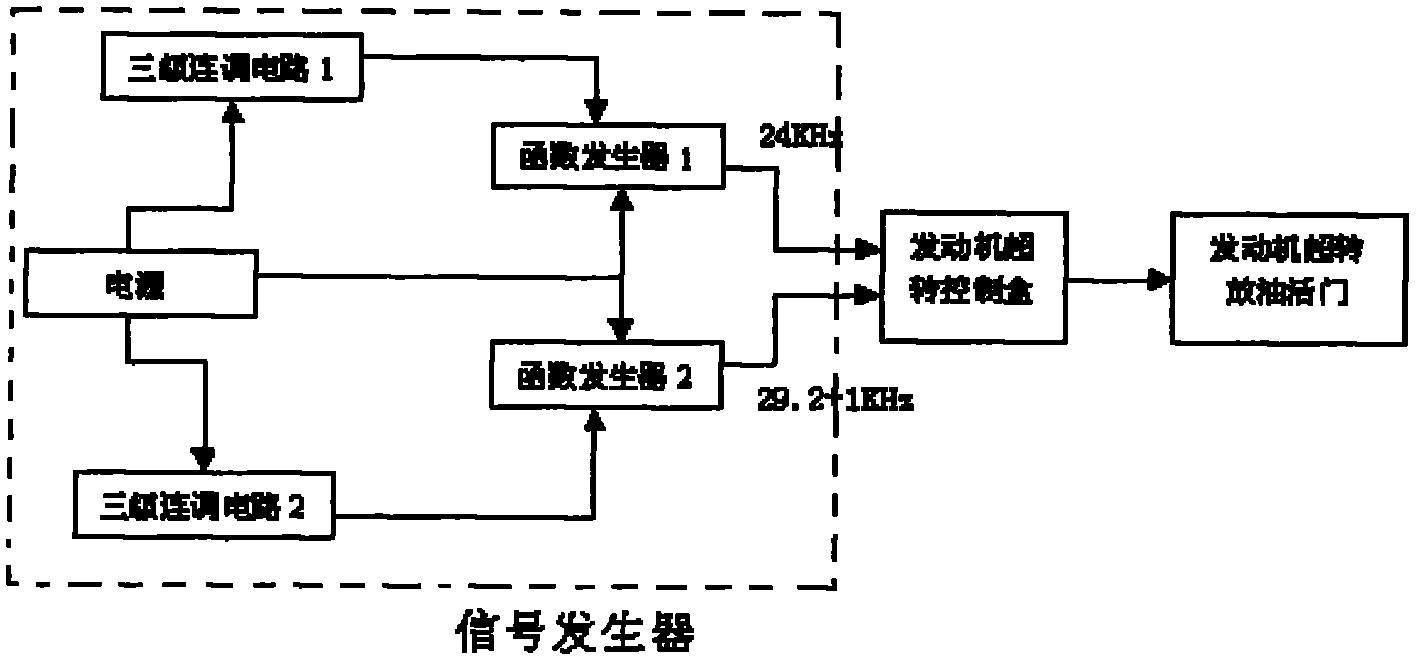

[0015] as attached figure 1 As shown, the signal generator of the hand-operated twin-engine helicopter turboshaft engine overrotation test system contains two completely independent main function circuit modules, and the signals output by the main function circuit modules represent two different working states of the engine. One of the signal generators is adjusted to a 24KHz signal of the engine free turbine normal speed, and the other signal generator is adjusted to a 29.2+1.0KHz signal of the engine overspeed speed. The two signals are input to the engine overspeed control box by the engine free turbine sensor interface , the engine overrun control box judges that the engine is in an overrun state and shuts down the engine. The engine over-rotation control box and the engine over-rotation oil discharge valve are components in the engine's own control system. Together with the signal generator, they constitute the hand-operated twin-engine helicopter turboshaft engine over-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com