Change-over switch gear

A transfer switch and switch technology, applied in the direction of contact drive mechanism, etc., can solve the problems of switch closing, opening failure, gear stuck, large impact of hinge point, etc., to achieve the effect of ensuring reliability and smooth meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

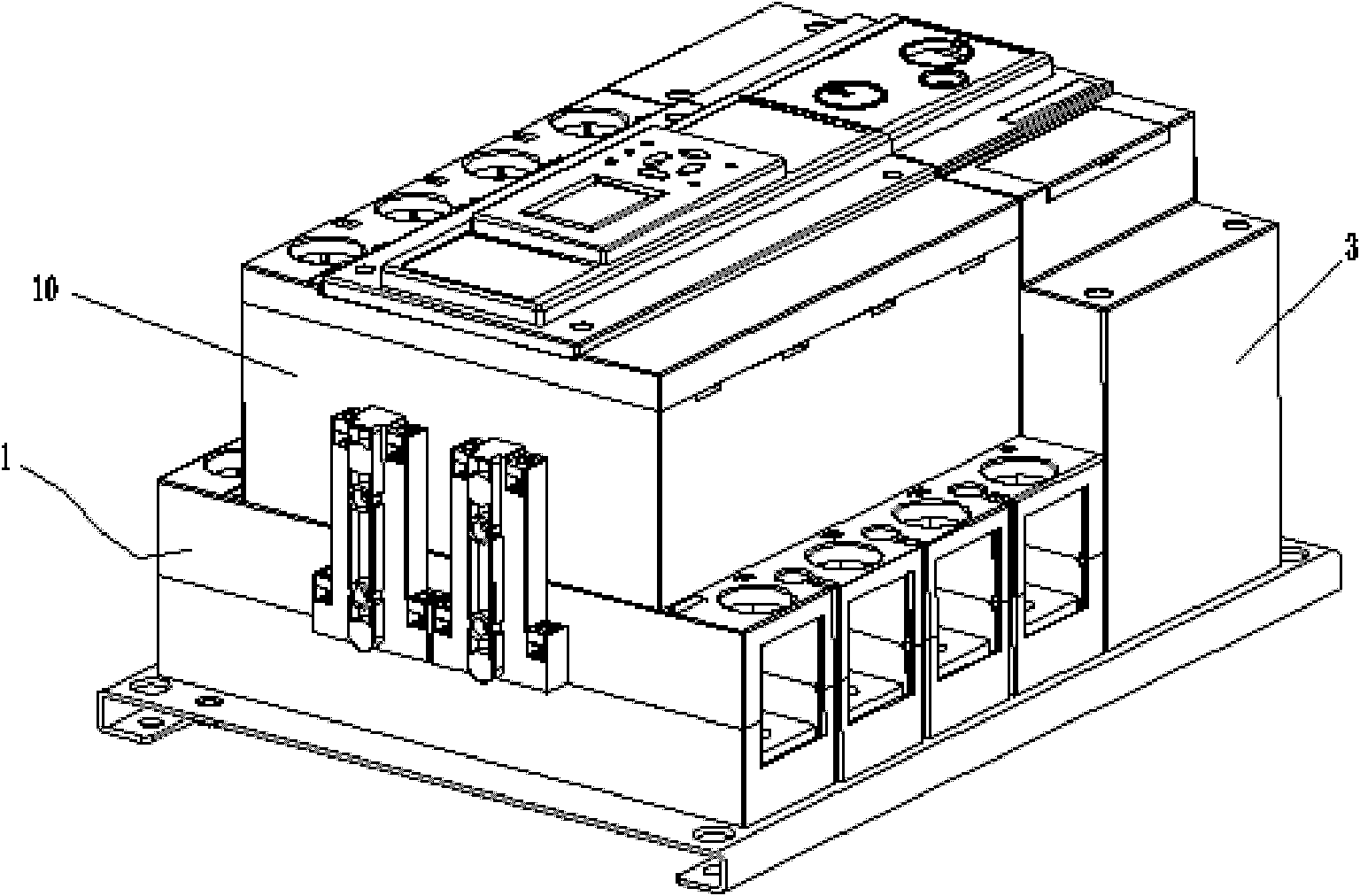

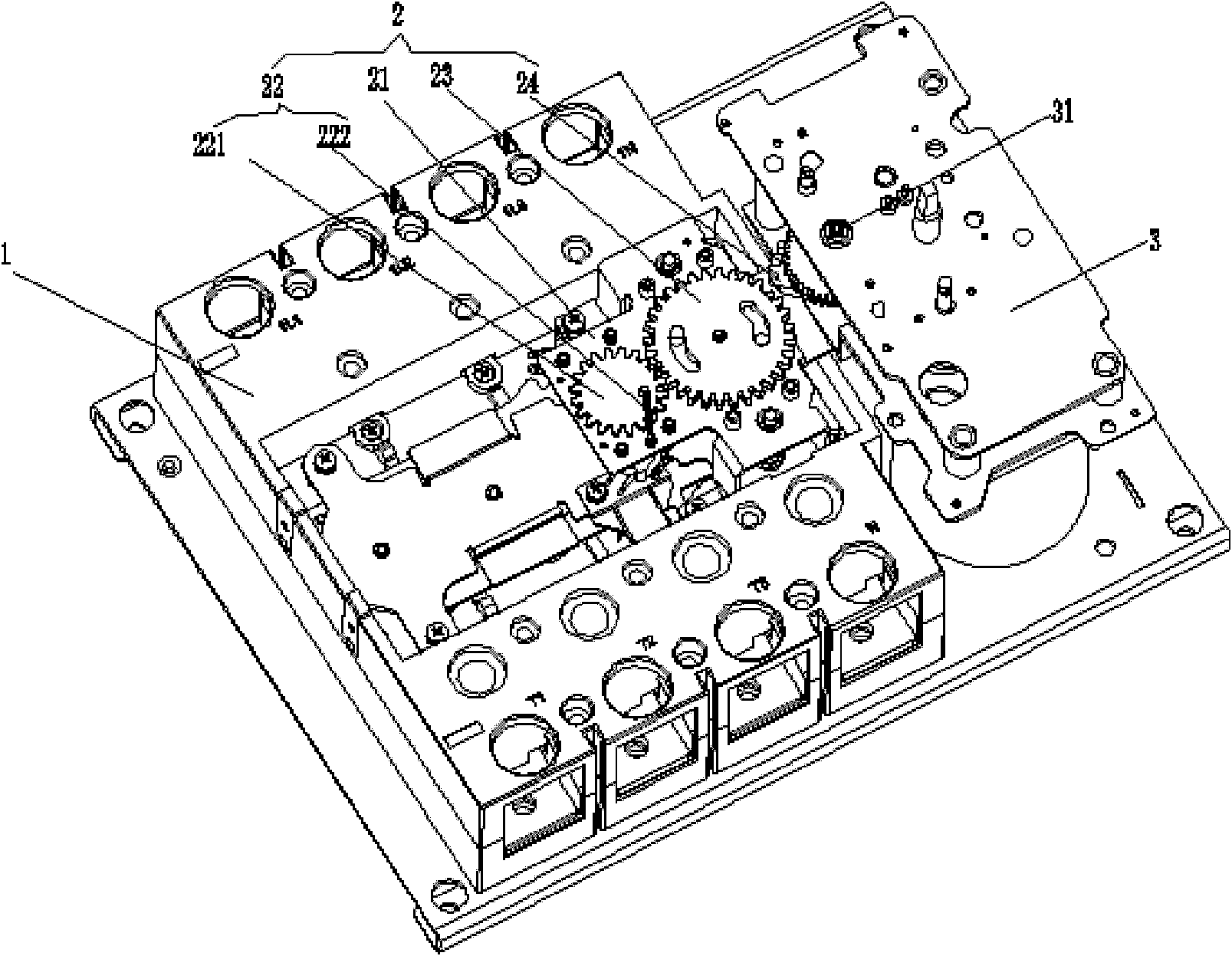

[0039] As shown in Figures 1 to 12, the changeover switch device of the present invention includes two switch bodies 1, 10 stacked up and down, a driving motor 3 with an output shaft 31, and a gear with gears inside each switch body. The spring energy storage mechanism connected to the transmission mechanism 2 includes an energy storage spring 41 and a pivot 42 .

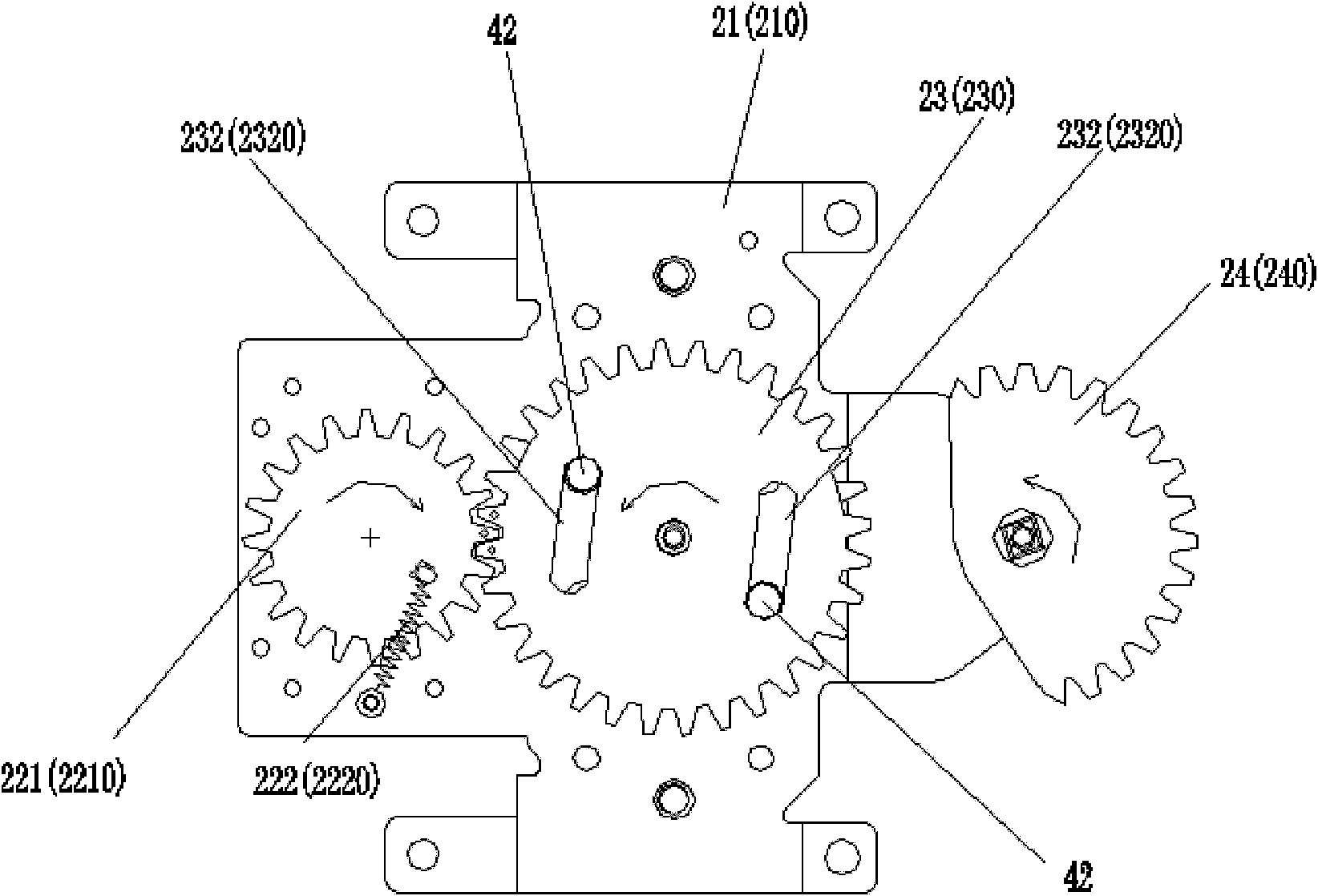

[0040] The gear transmission mechanism 2 includes two brackets 21, 210 respectively fixed on the switch bodies 1, 10, reset gear assemblies 22, 220 respectively arranged on the brackets 21, 210, respectively pivoted on the brackets 21, 210 and connected with the reset gear assembly. The switch gears 23, 230 meshed with the gear assemblie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com