Multipoint dispensing process and LED (light emitting diode) device

A technology for LED devices and dispensing technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven distribution of phosphors on the surface of the chip, uneven distribution of phosphor glue, affecting the uniformity of light output, etc. Excitation efficiency, increased contact area, good uniformity of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

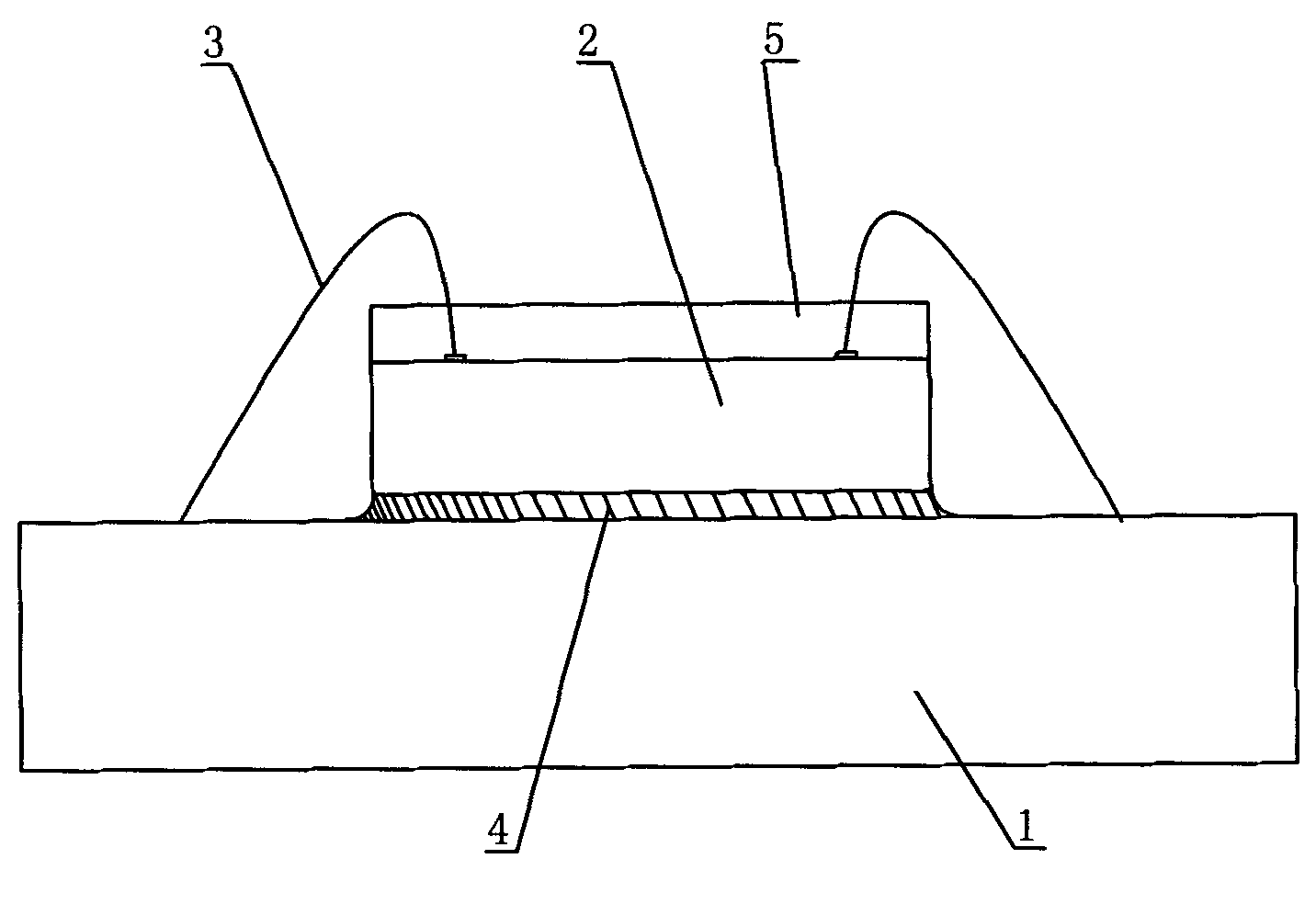

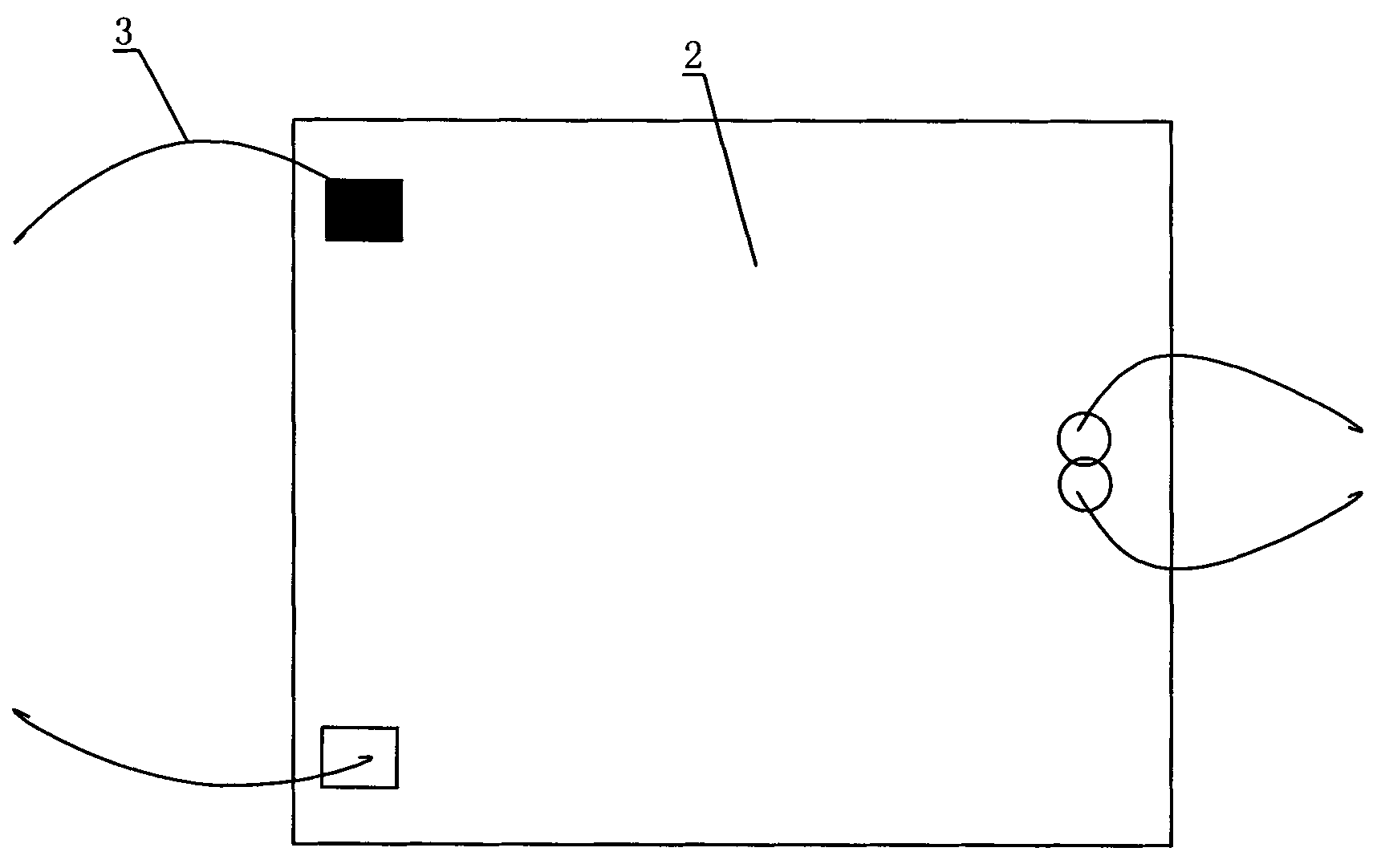

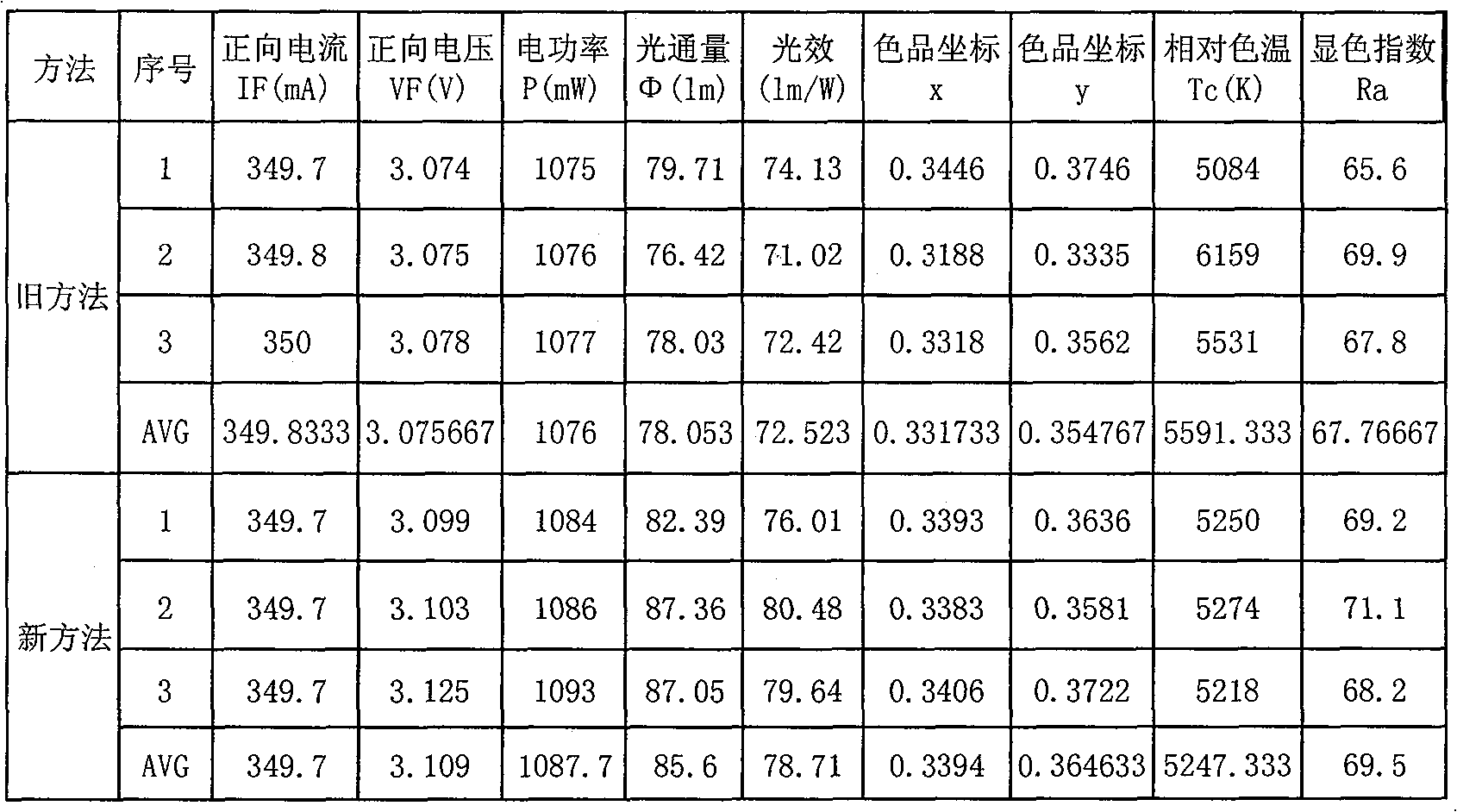

[0031] The manufacture of the above LED devices is completed by a multi-point dispensing process, and the specific steps are as follows:

[0032] (1) Perform dehumidification treatment on the bracket 1 before die bonding.

[0033] (2) Fix the chip 2 on the support 1 through silver glue, and fix it by baking to complete the fixing operation;

[0034] (3) Weld the positive and negative poles of the chip 2 to the support 1 through the gold wire 3 .

[0035] (4) Use the automatic glue dispensing equipment to put the fluorescent powder glue on the surface of the chip in multiple points. The distance between adjacent fluorescent powder glue points is 10-1000 μm, and 10 μm is selected in this embodiment; wherein, phosphor powder and glue are added to the glue mixing container according to the ratio of 1.5:1 to 1:1000, and the centrifugal mixer After stirring and vacuumizing, the degree of vacuum during vacuuming is 0.01-1000 Pa, and 0.01 Pa is selected in this embodiment.

[0036]...

Embodiment 2

[0039] The manufacture of the above LED devices is completed by a multi-point dispensing process, and the specific steps are as follows:

[0040] (1) Perform dehumidification treatment on the bracket 1 before die bonding.

[0041] (2) The chip 2 is fixed on the support 1 by silver glue, and fixed by baking to complete the fixing operation.

[0042] (3) Weld the positive and negative poles of the chip 2 to the support 1 through the gold wire 3 .

[0043] (4) Use the automatic glue dispensing equipment to put the fluorescent powder glue on the surface of the chip in multiple points. The distance between adjacent fluorescent powder glue points is 10-1000 μm, and 1000 μm is selected in this embodiment, and no phosphor powder glue is placed at the position of the gold wire; wherein, the phosphor powder glue is composed of phosphor powder and glue according to the ratio of 1.5:1 to 1: The ratio of 1000 is added to the glue mixing container, and it is formed after being stirred and...

Embodiment 3

[0047] The manufacture of the above LED devices is completed by a multi-point dispensing process, and the specific steps are as follows:

[0048] (1) Perform dehumidification treatment on the bracket 1 before die bonding.

[0049] (2) The chip 2 is fixed on the support 1 by silver glue, and fixed by baking to complete the fixing operation.

[0050] (3) Weld the positive and negative poles of the chip 2 to the support 1 through the gold wire 3 .

[0051] (4) Use the automatic dispensing equipment to put the fluorescent powder glue on the surface of the chip in multiple points. The distance between adjacent fluorescent powder glue points is 10-1000 μm, and in this embodiment, 520 μm is selected, and no fluorescent powder glue is placed at the position of the gold wire; wherein, the fluorescent powder glue is composed of phosphor powder and glue according to the ratio of 1.5:1 to 1: The ratio of 1000 is added to the glue mixing container, and it is formed after being stirred and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com