Method and device for arranging matrix array assembly

A technology of matrix columns and components is applied in the field of components and devices of matrix column components, which can solve the problems of wasting component placement time and reducing production efficiency, and achieve the effect of saving component placement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

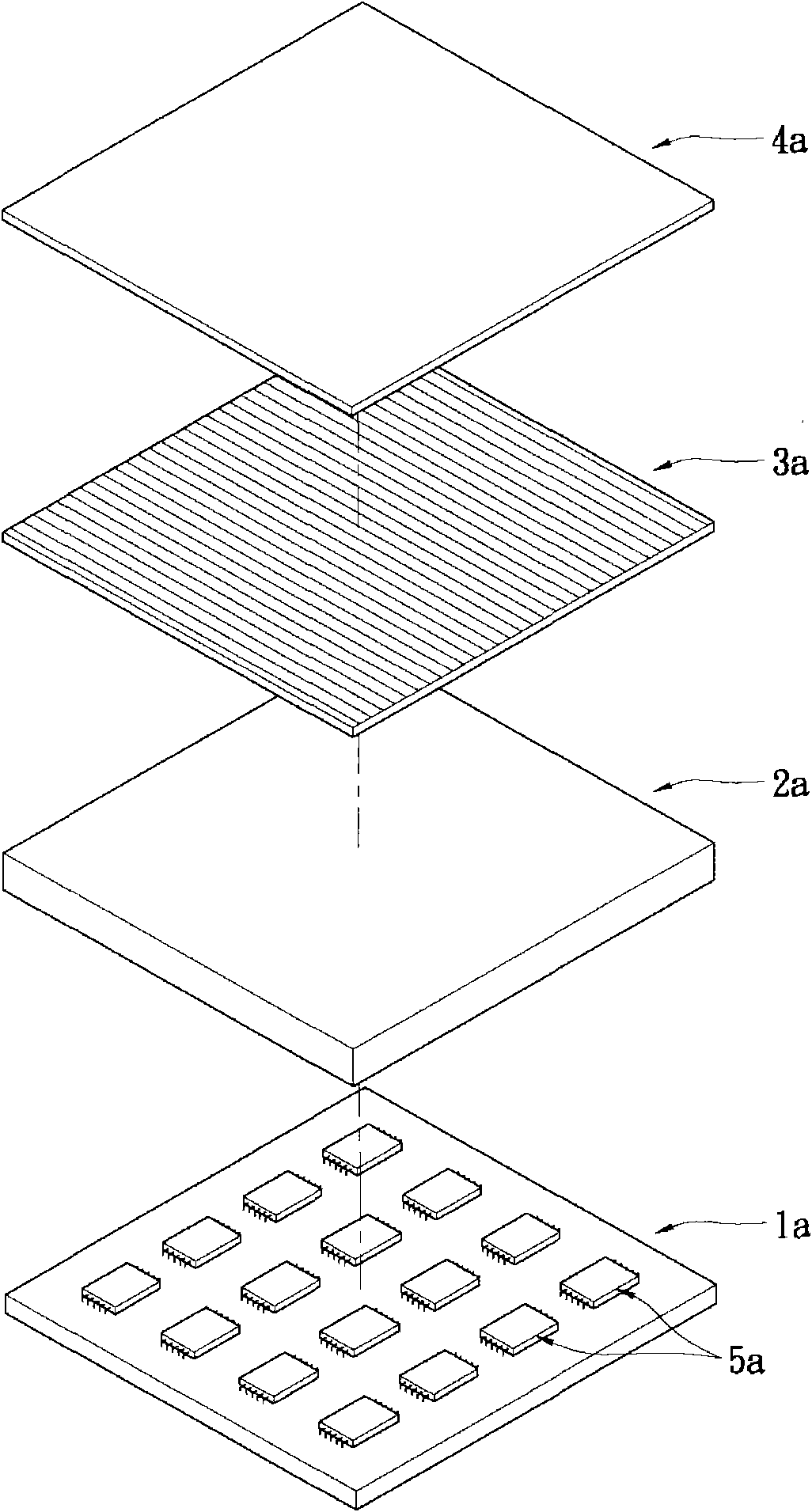

[0028] see figure 2 , the present invention provides a kind of inserting method of matrix column component, comprises steps and has:

[0029] S101, providing a substrate (PCB or FPC), where a control circuit is arranged on the substrate.

[0030] S103, using a solder paste printing machine to form a plurality of pads (Pads) on the substrate, the pads are electrically connected to the control circuit, and the position of the pads corresponds to the position on the substrate where the component is to be placed, so as to adhere and fix the component to the substrate superior. The solder pad is mainly composed of tin powder, flux and anti-sagging agent, and the solder pad can also be called solder. The particle size and composition of tin powder affect the melting point temperature and solderability of the solder pad. Smaller and more uniform tin powder has better fluidity and is easier to form.

[0031] S105, using an optical positioning device to identify the position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com