Heating system for treating a fibrous material web

A heating system and web technology, applied in the direction of textiles and papermaking, paper machines, dryers, etc., can solve the problems of high consumption of cooling water, and achieve the effect of reducing cooling water consumption, reducing energy costs, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

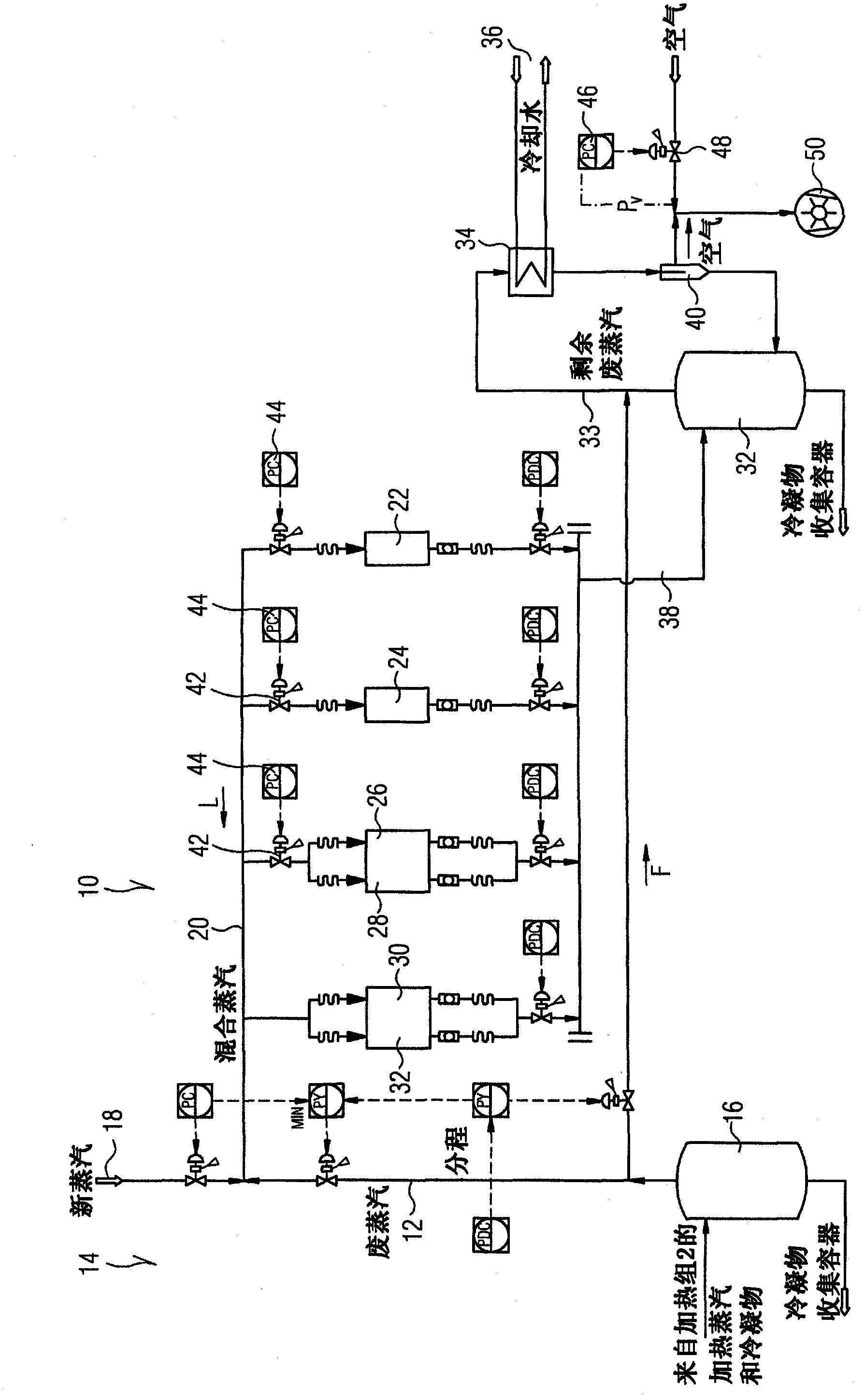

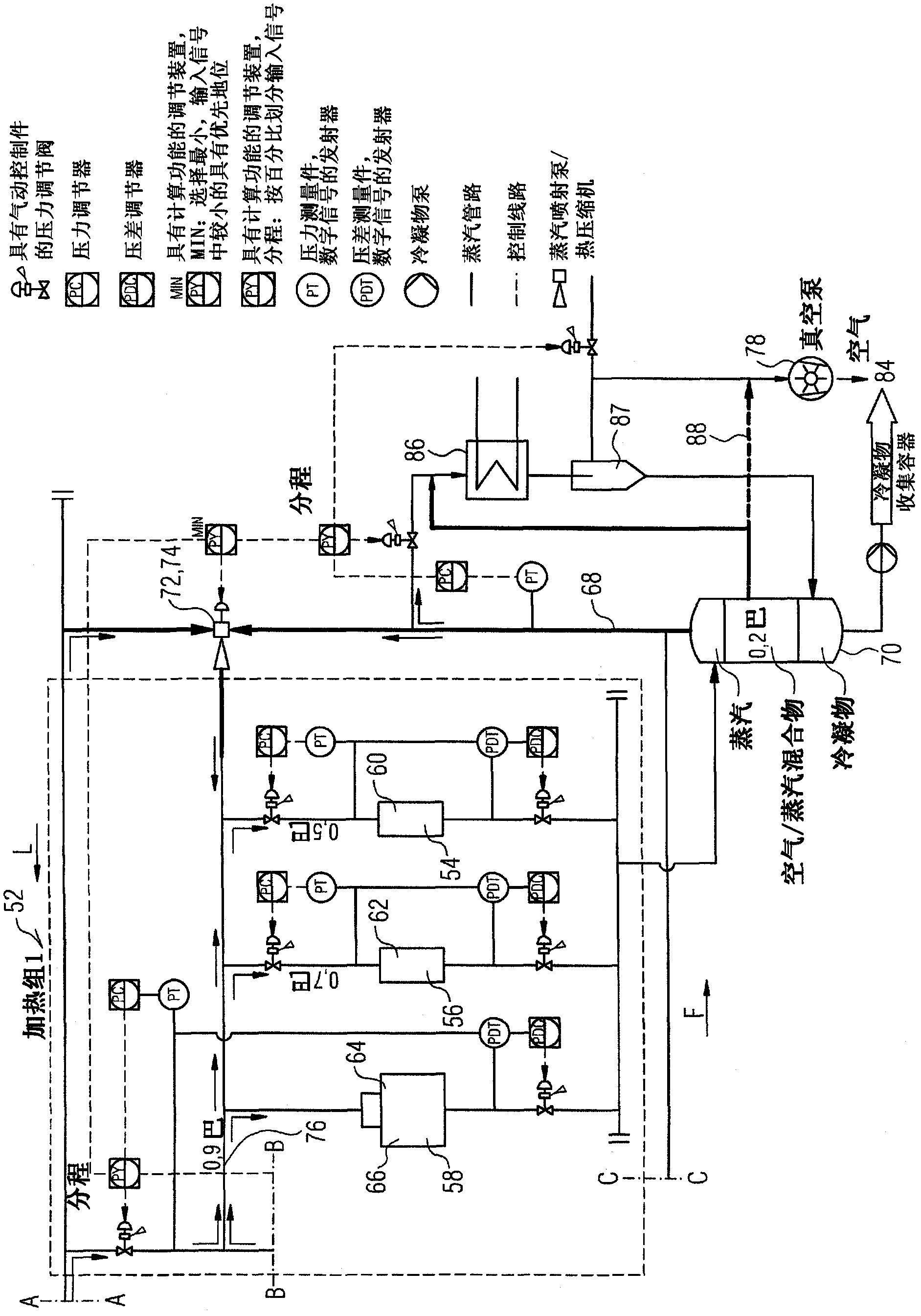

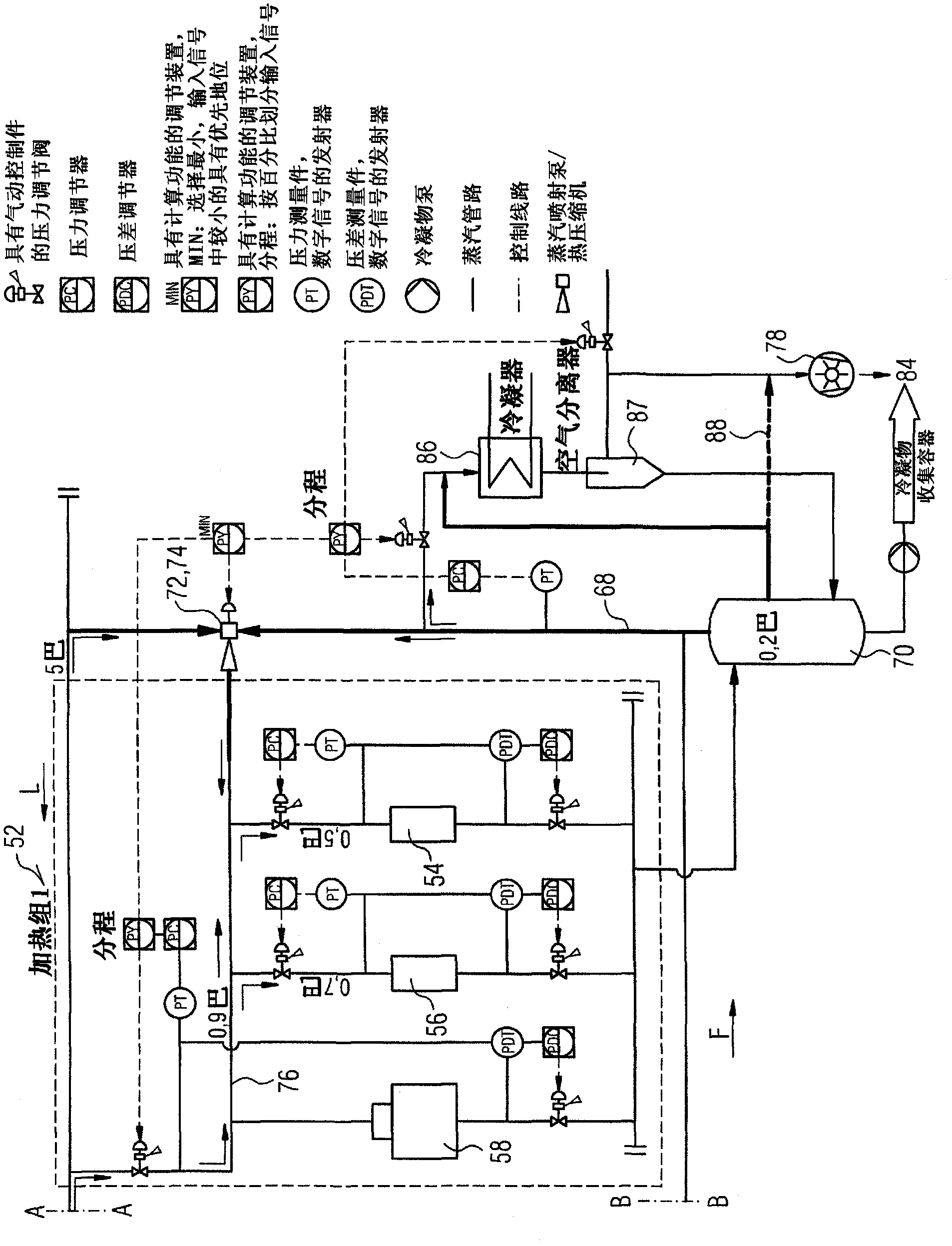

[0035] figure 2The first heating group 52 viewed in the direction of web travel L of an exemplary embodiment of the heating system according to the invention is shown in a simplified schematic diagram. The heating system is used, for example, for treating fibrous webs, especially paper, cardboard or tissue webs, and comprises one or more heating groups, each comprising one or more heating stages , the heating stages each comprise one or more drying cylinders heated with steam.

[0036] If according to figure 2 It can be seen that the first heating group 52 comprises, for example, three heating stages 54-58. In this case, the two first heating stages 54 , 56 each include, for example, only one drying cylinder 60 or 62 , while the third heating stage 58 here includes, for example, two drying cylinders 64 and 66 .

[0037] Means are provided for compressing the residual waste steam 68 remaining after the last heating stage or heating group 52 of the heating system seen along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com