Apparatus for shining shoes

A leather shoe and glossy technology, which is applied in household cleaning devices, boots and shoes cleaning, cleaning equipment, etc., can solve the problems of long time consumption and inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, an embodiment example of the present invention will be specifically described with reference to the drawings.

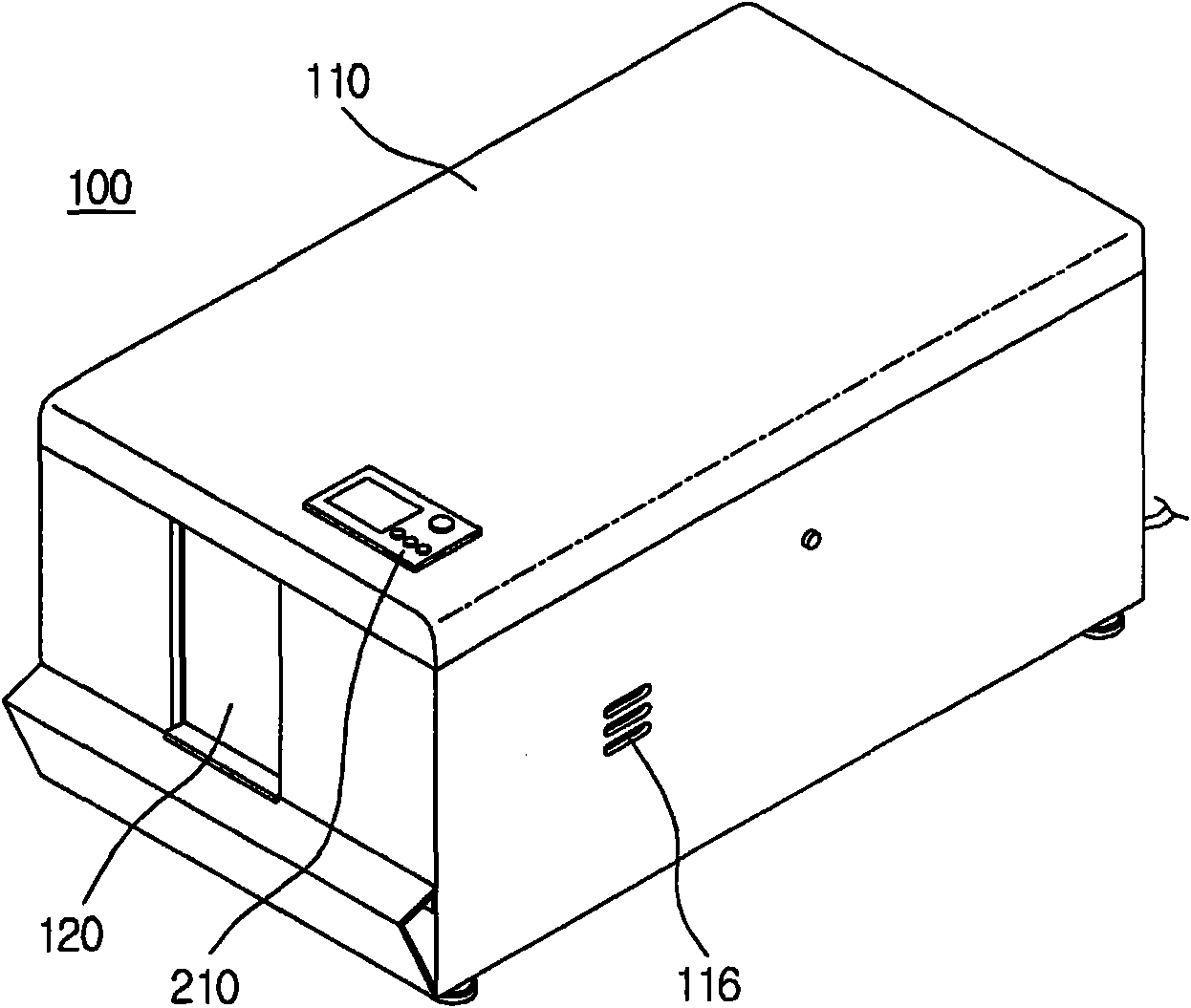

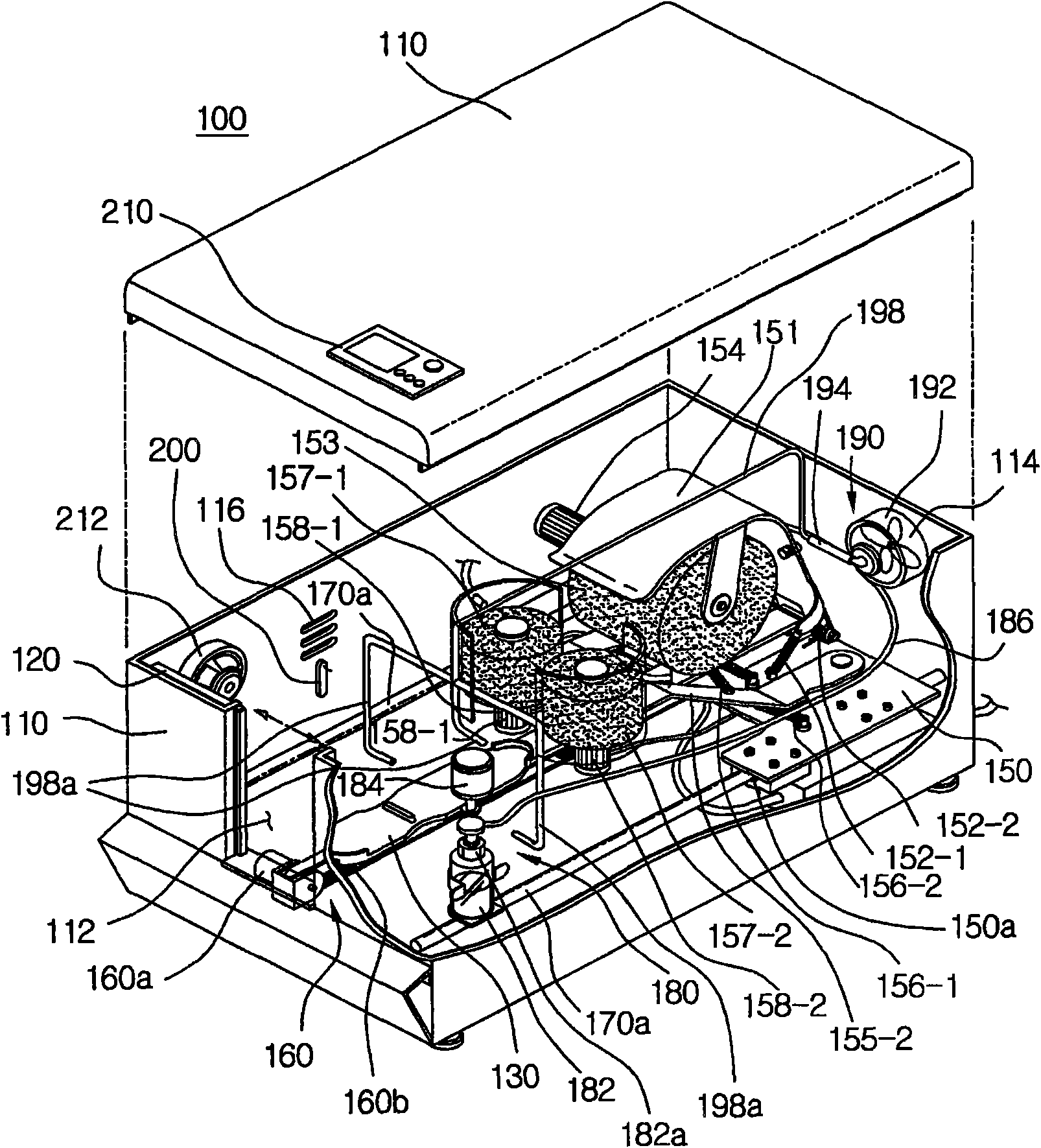

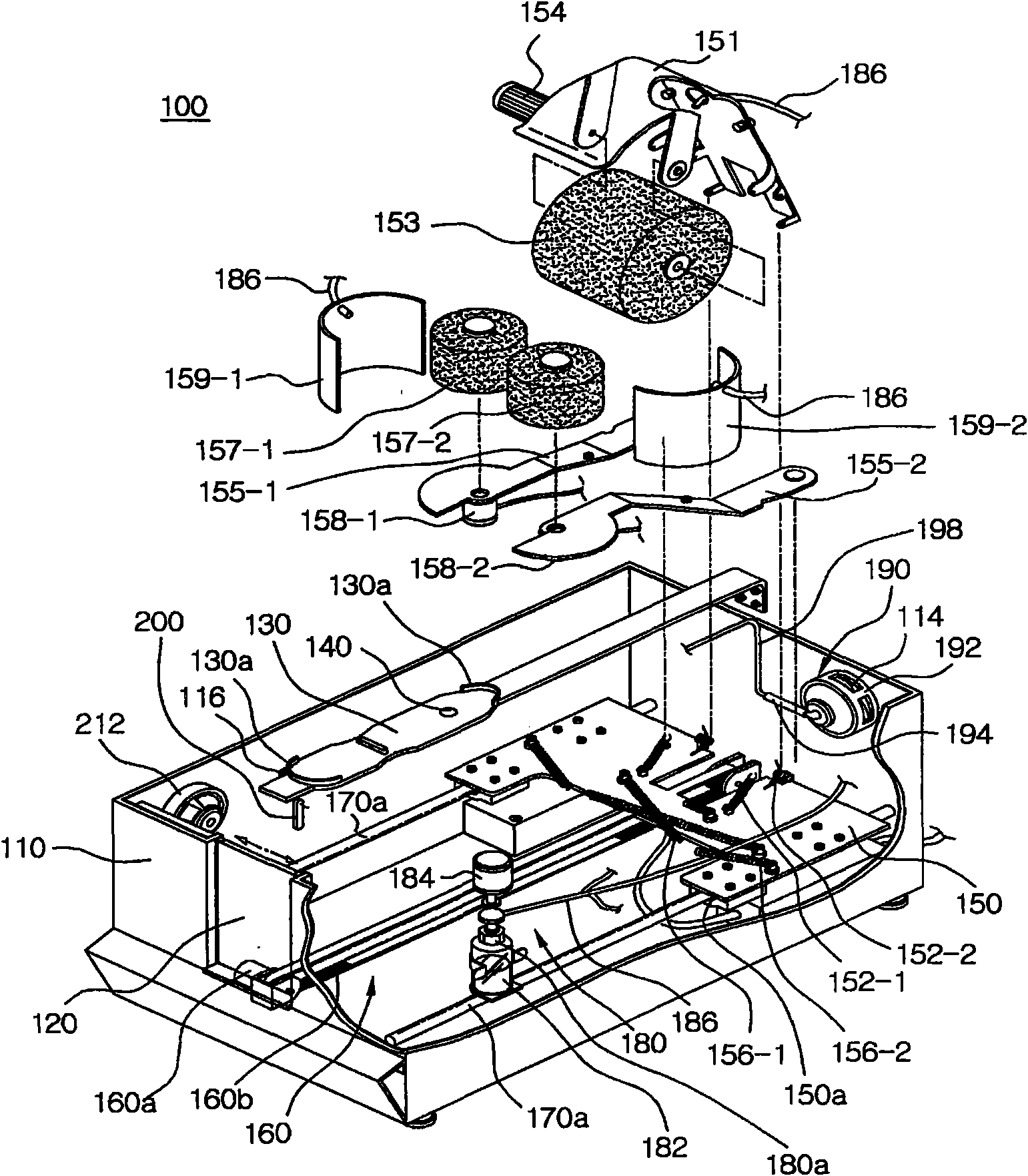

[0054] figure 1 It is a schematic perspective view showing the appearance of the shoe gloss device of the present invention. figure 2 It is a perspective view showing the inner device of the shoe gloss device of the present invention. image 3 It is an exploded oblique view showing the internal device of the leather shoe gloss device of the present invention.

[0055] The light-emitting principle of the leather shoe gloss device (100) used in the present invention is to add mink oil, castor oil, jojoba oil and other oil components to the conventional liquid shoe polish, and configure it into an oily shoe cream with a volume content of 5-20%. , through the sea surface, rub it evenly on the leather shoes, and after a certain period of time (3-10 minutes) in a high-temperature atmosphere of 60-80 ° C, it will naturally emit a high degree of gloss....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com