Upper die anti-cracking structure of closed type cold extrusion planetary gear die

A planetary gear and cold extrusion technology, which is applied in the direction of metal extrusion dies, etc., can solve the problems that affect the popularization and application of closed cold extrusion technology, large economic losses, and high manufacturing costs of closed cold extrusion dies, so as to avoid Cracking failure, increasing the diameter of the upper ejector pin, and the effect of increasing the diameter of the upper ejector pin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

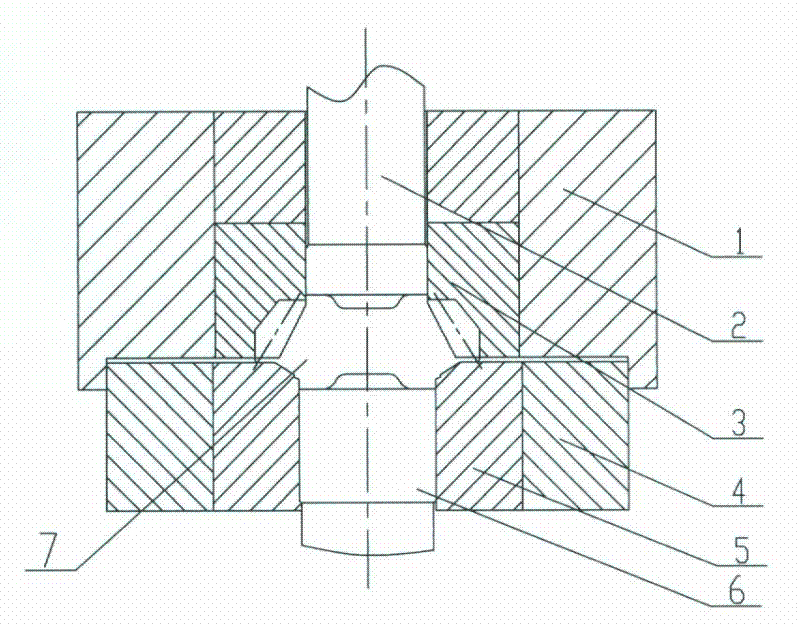

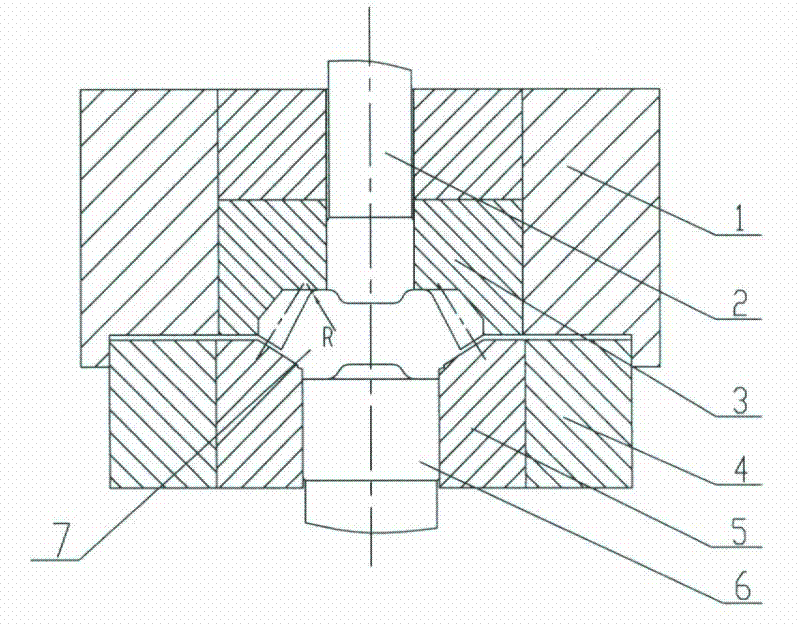

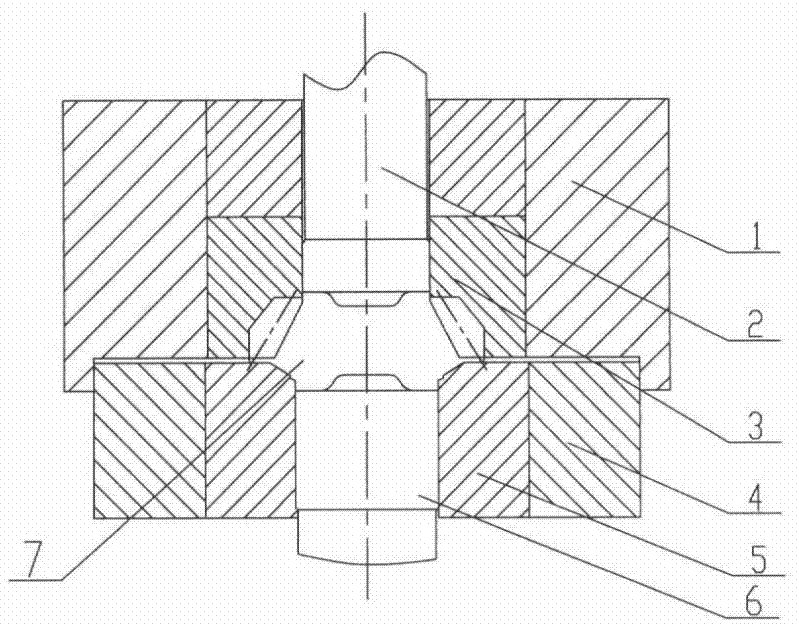

[0012] According to the attached figure 1 And the present invention will be further described in conjunction with embodiment.

[0013] figure 1 The upper die crack prevention structure of a closed cold extrusion planetary gear die is shown, which includes two parts: a fixed mandrel structure and a die body. The positioning structure is an outer sheath, which is composed of a vertical upper mold cover 1 and a lower mold cover 4 coaxially fitted together, and the upper mold cover 1 and the lower mold cover 4 have the same inner hole size. The mold body is composed of an upper mold 3, a lower mold 5, an upper ejector pin 2 and a lower ejector pin 6. The upper mold 3 is disc-shaped, and its mold cavity is tooth-shaped, and the middle longitudinal axis hole is in clearance fit with the upper ejector pin 2 , the lower mold 5 is also disc-shaped, the mold cavity is an inner pit, and the middle longitudinal axis hole is in clearance with the lower ejector rod 6. inner hole cleara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com