Excavation construction method for unsymmetrical small-space tunnel

A tunnel excavation and construction method technology, which is applied in the direction of tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as unfavorable structural stress, shortened construction period, and limited effect of partial pressure integrity, and achieve soil excavation and The support structure is simple, the stability of the surrounding rock is improved, and the overall effect is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

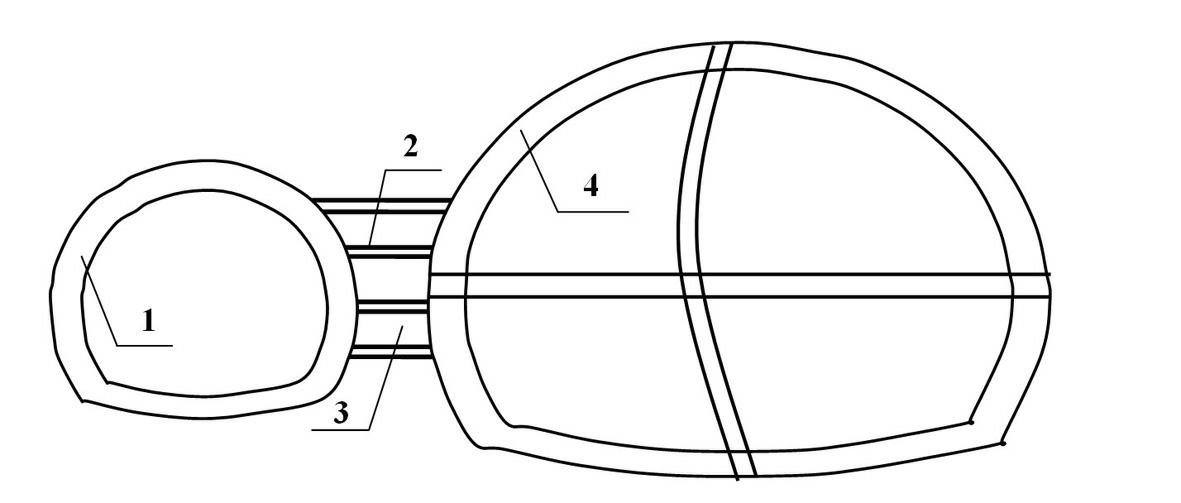

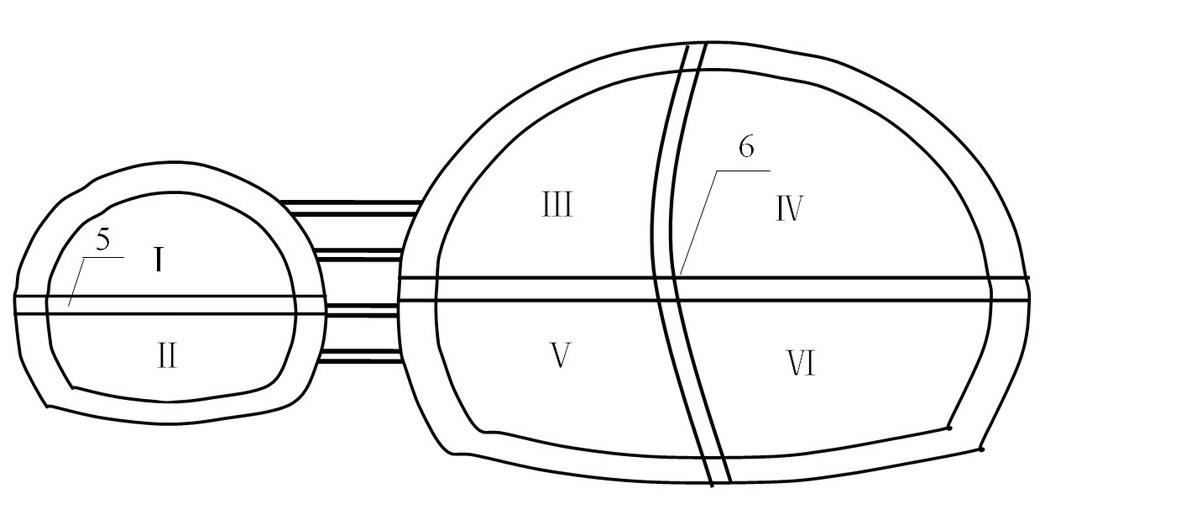

[0016] Taking the small-spacing tunnel composed of single-track and double-track tunnels as an example, the accompanying drawings illustrate that the single-track tunnel is excavated by the method of two upper and lower steps, and the double-track tunnel is excavated by two steps and four parts. Other relevant features are further explained in detail to facilitate the understanding of technical personnel in the same industry:

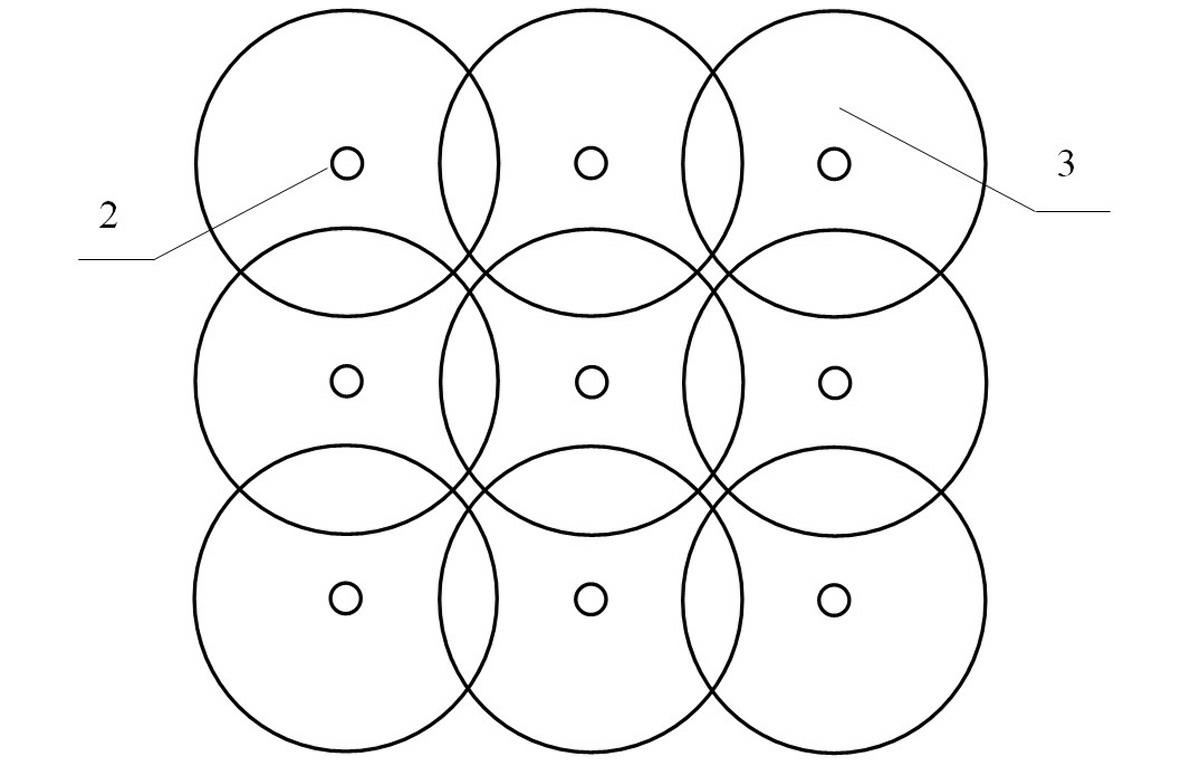

[0017] Such as Figure 1-3 As shown, the labels respectively indicate: small-span tunnel support 1, grouting anti-tension, anti-tension anchor 2, grouting reinforcement rock formation 3, initial support of long-span tunnel 4, temporary support for small-span tunnel excavation 5, large Temporary support for span tunnel excavation 6; upper excavation of small-span tunnel , The lower part of the small-span tunnel is excavated II, and the four parts of the long-span tunnel are excavated III, IV, V, VI.

[0018] An asymmetric small-spacing tunnel excavati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com