Method and device for increasing sucking capability and distance of suction opening

A technology of suction capacity and suction port, which is applied in pump devices, liquid variable capacity machinery, machines/engines, etc., can solve the problems of small fresh air shielding capacity, weak jet rotation strength, and reduced suction efficiency, and achieves the scope of application. Wide, strong suction ability, improve the effect of suction ability and distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

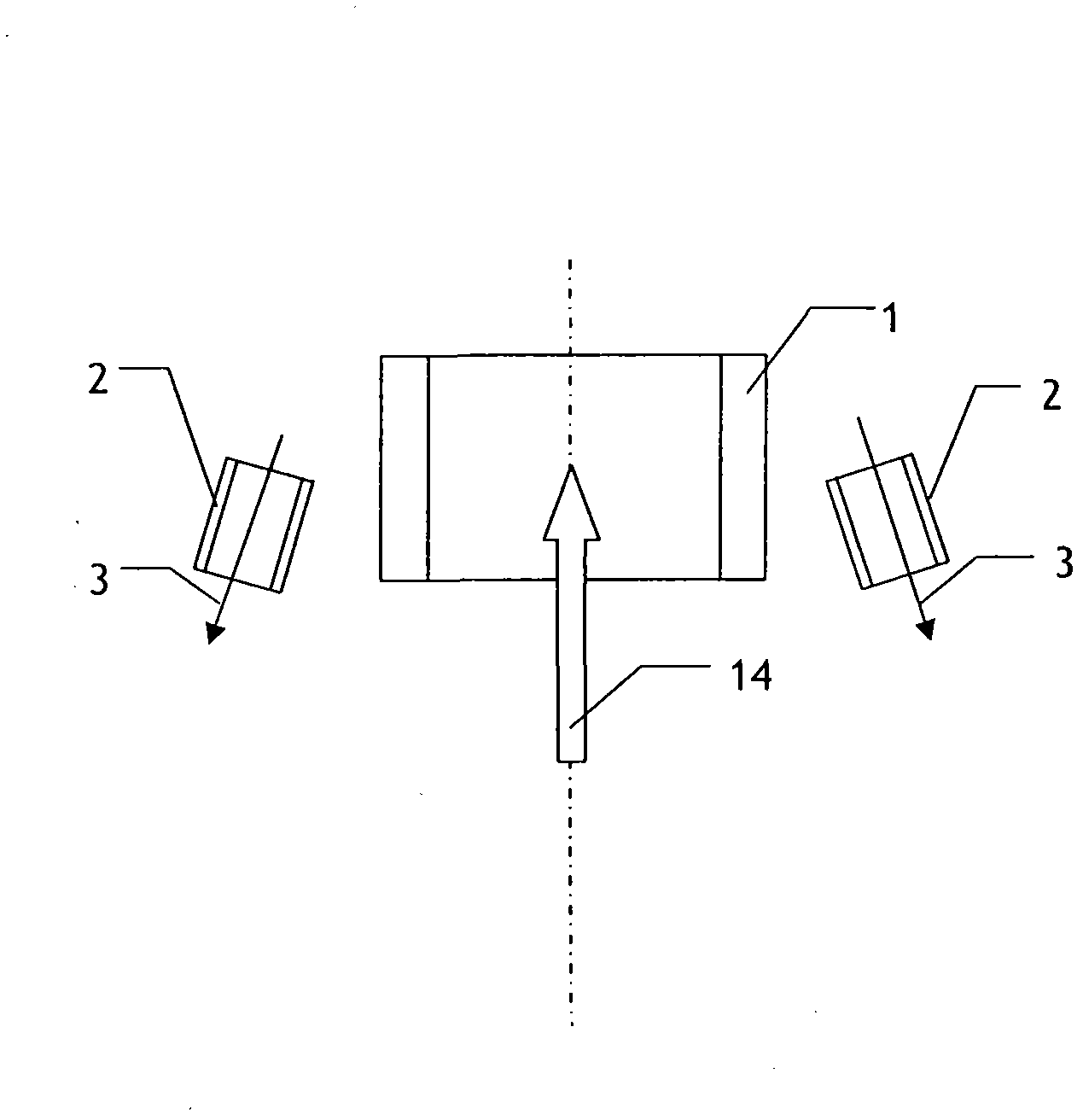

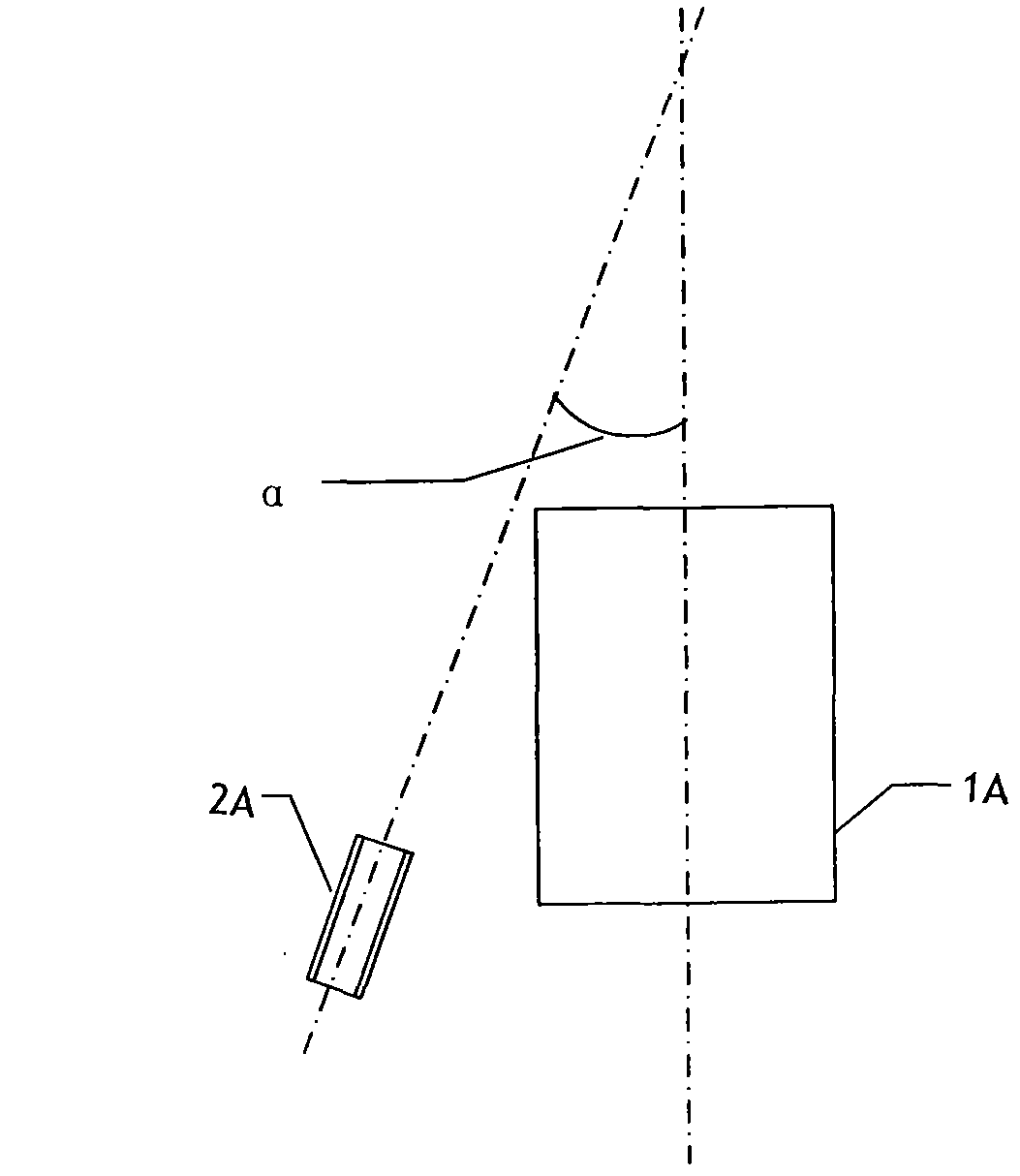

[0015] figure 1 It is a schematic diagram of the principle of the method of the present invention. see figure 1 The method for improving the suction capacity and distance of the suction port in the present invention is to set a number of jet nozzles 2 around the suction port driven by the power source to rotate around the suction port and to eject jets. The axis of the jet nozzle is inclined to the axis of the suction port. Jet flow is air flow (or steam or gas-liquid mixture).

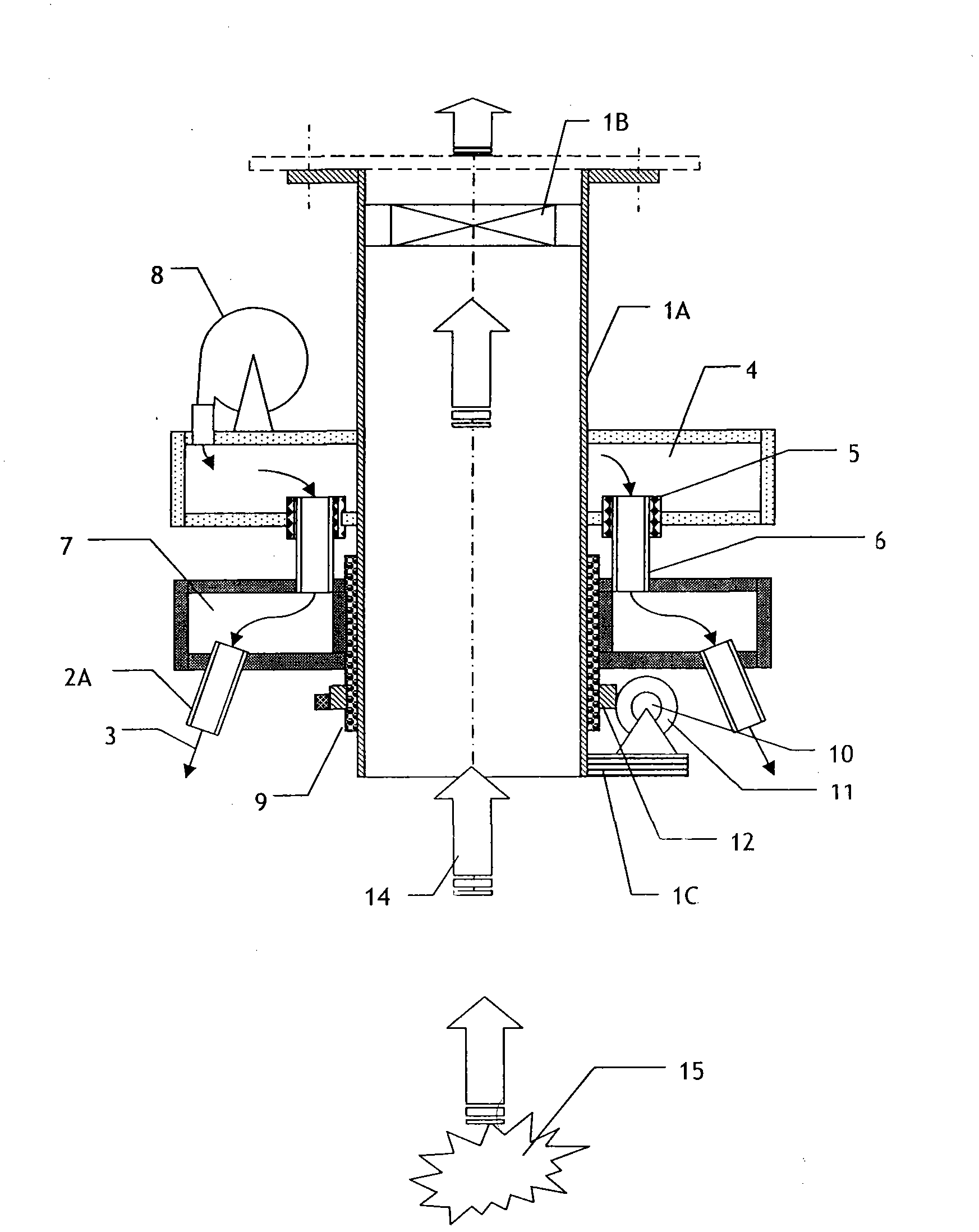

[0016] figure 2 , image 3 It is a schematic diagram of the device structure of the present invention. see Figure 2 ~ Figure 3 The device of the present invention comprises an exhaust pipe 1A, an exhaust fan 1B installed at the outlet of the exhaust pipe, which is successively installed on the outer periphery of the exhaust pipe and is installed on the exhaust pipe through an outsourced rotary bearing 9, a gear reduction transmission mechanism 12 and a worm gear reducer 11. The rotating bellow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Radial angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com