LED (light emitting diode) pluggable pipe

A technology for plugging and unplugging tubes and light source components is applied in the cooling/heating device, lighting device, light source and other directions of lighting devices, which can solve the problems of LED lamps and lanterns, such as heat dissipation, performance, electrical stability, waste mercury pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

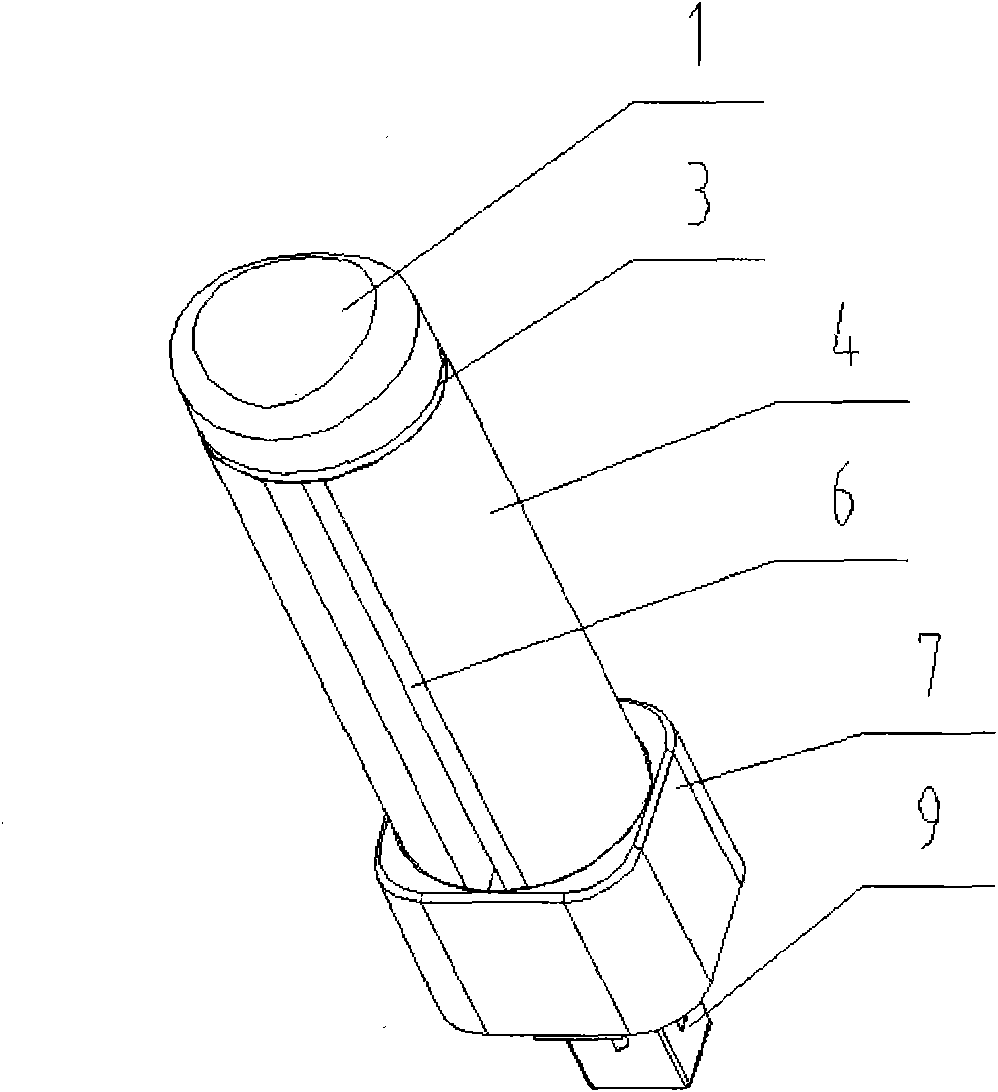

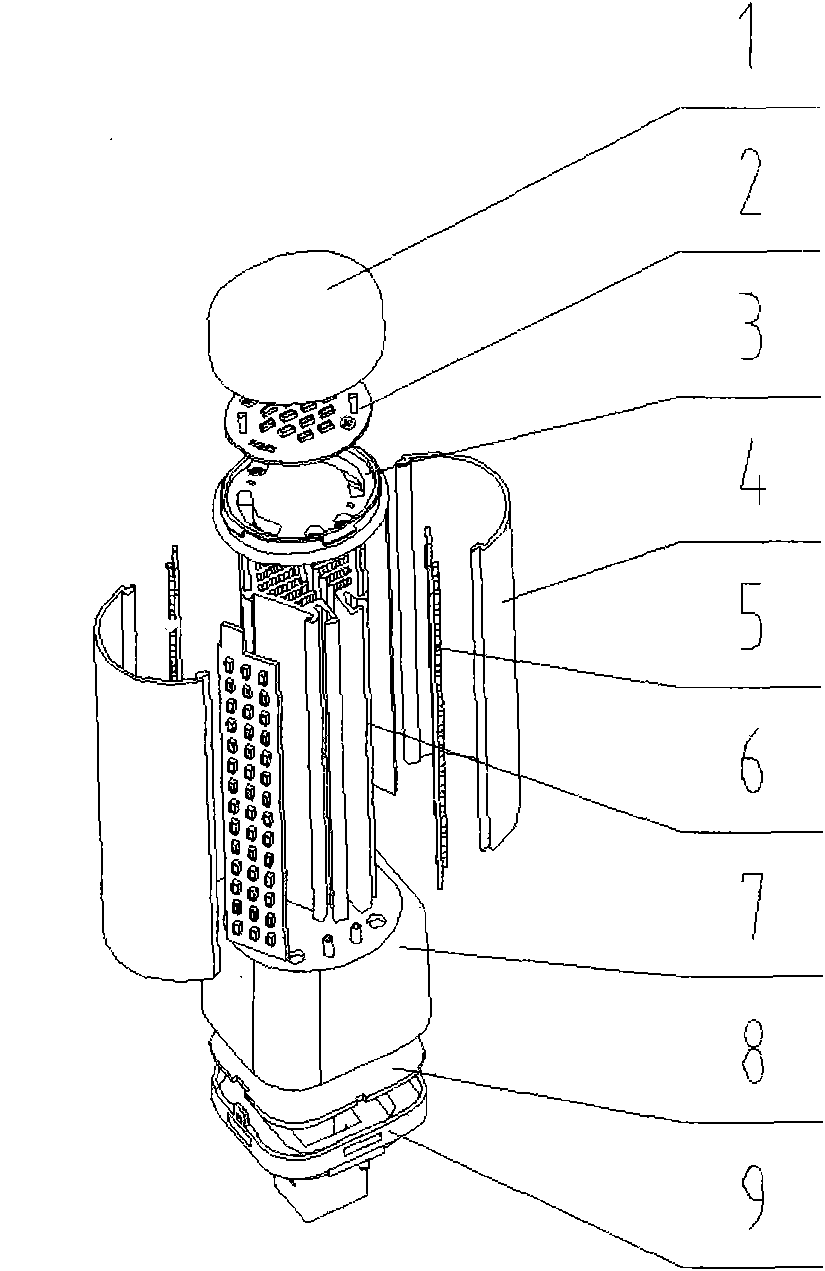

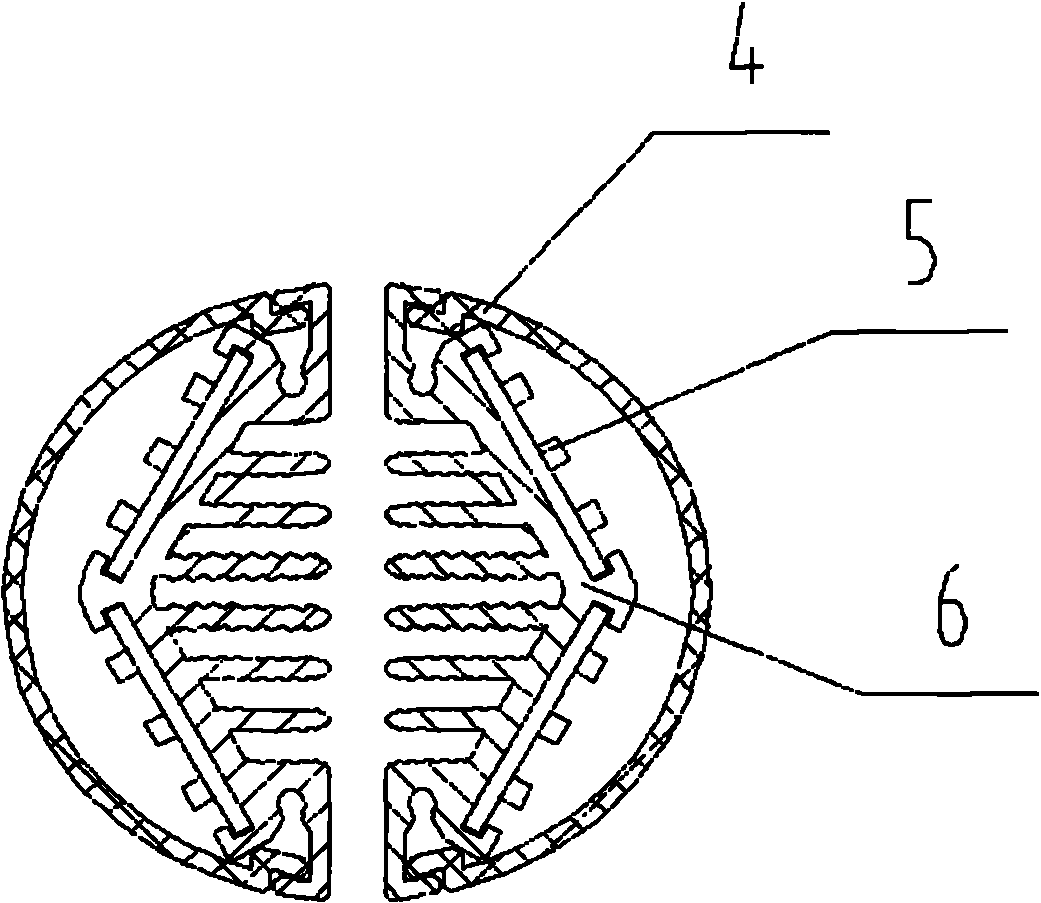

[0017] This embodiment is 11W. The top light transmission cover (1), the top light source assembly (2), and the top light source assembly mounting part (3) form an elliptical light source module. The side light transmission cover (4), the side light source assembly (5 ), heat dissipation profiles (6) to form a bar-shaped light source module, the present embodiment uses three bar-shaped light source modules plus the top elliptical light source module, and each bar-shaped light source module is provided with two The side light source assembly (5) is pasted on the "V"-shaped heat dissipation profile (6). Each side light source assembly (5) uses 84 pieces of 0.06W LED light sources, which are welded on the aluminum substrate, and the back of the aluminum substrate is coated with heat-conducting silicone grease Attached to the radiator, there is a ventilation gap between the radiators to effectively dissipate heat.

[0018] The above is only a preferred embodiment of an LED plug-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com