Sealing ring for underwater experiment of stainless steel pipe

A stainless steel tube, experimental technology, applied in the direction of using liquid/vacuum to measure liquid tightness, using stable tension/pressure to test material strength, measuring devices, etc., can solve the problem that the sealing ring cannot meet the sealing requirements, only Can be replaced and other problems, to achieve the effect of using effect and life enhancement, reducing the number of replacements, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

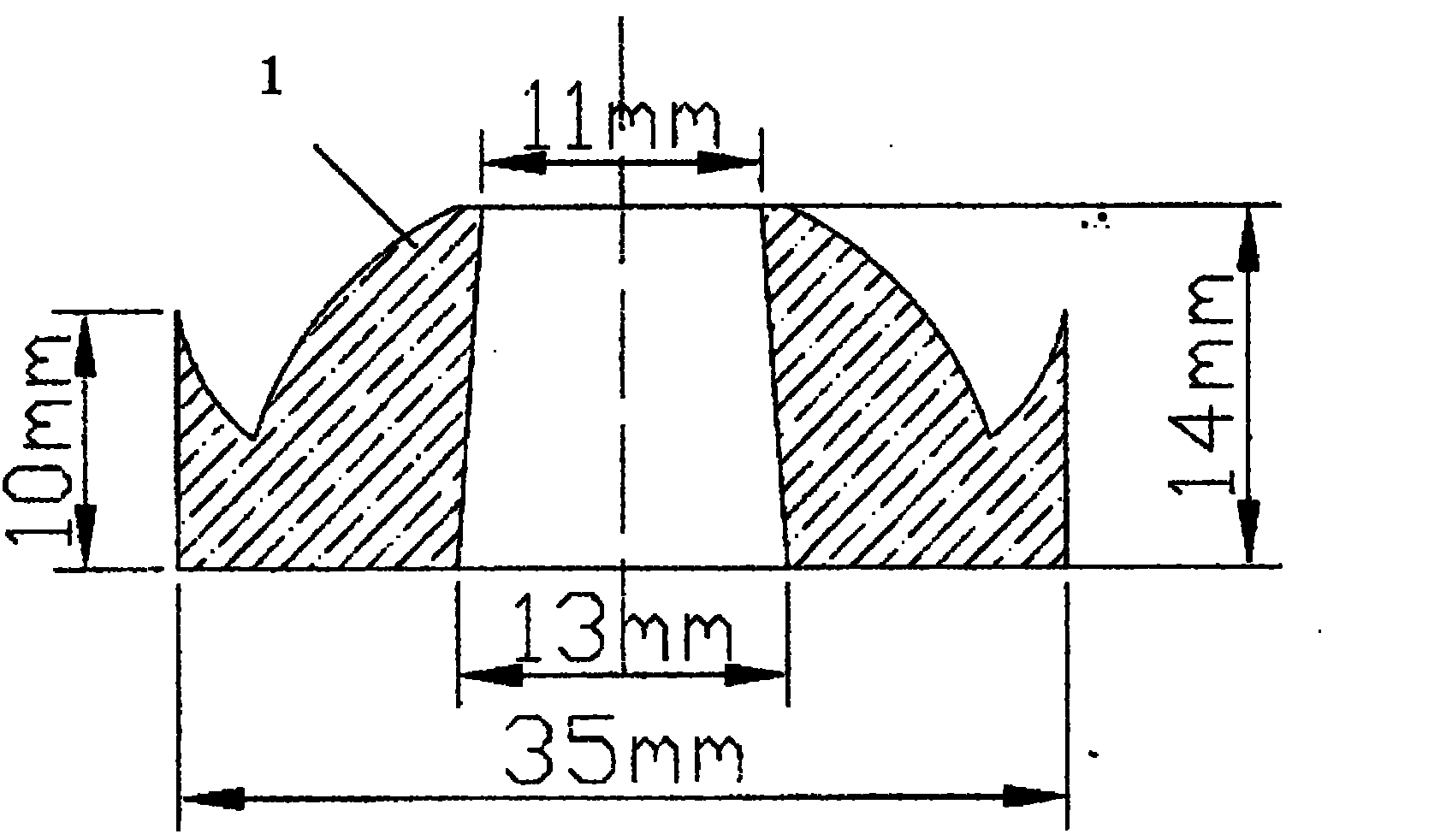

[0012] Depend on figure 1 It can be seen that the present invention includes: a body 1; the inner diameter of the body 1 gradually decreases in diameter from the flat end on one side to the tip on the other side.

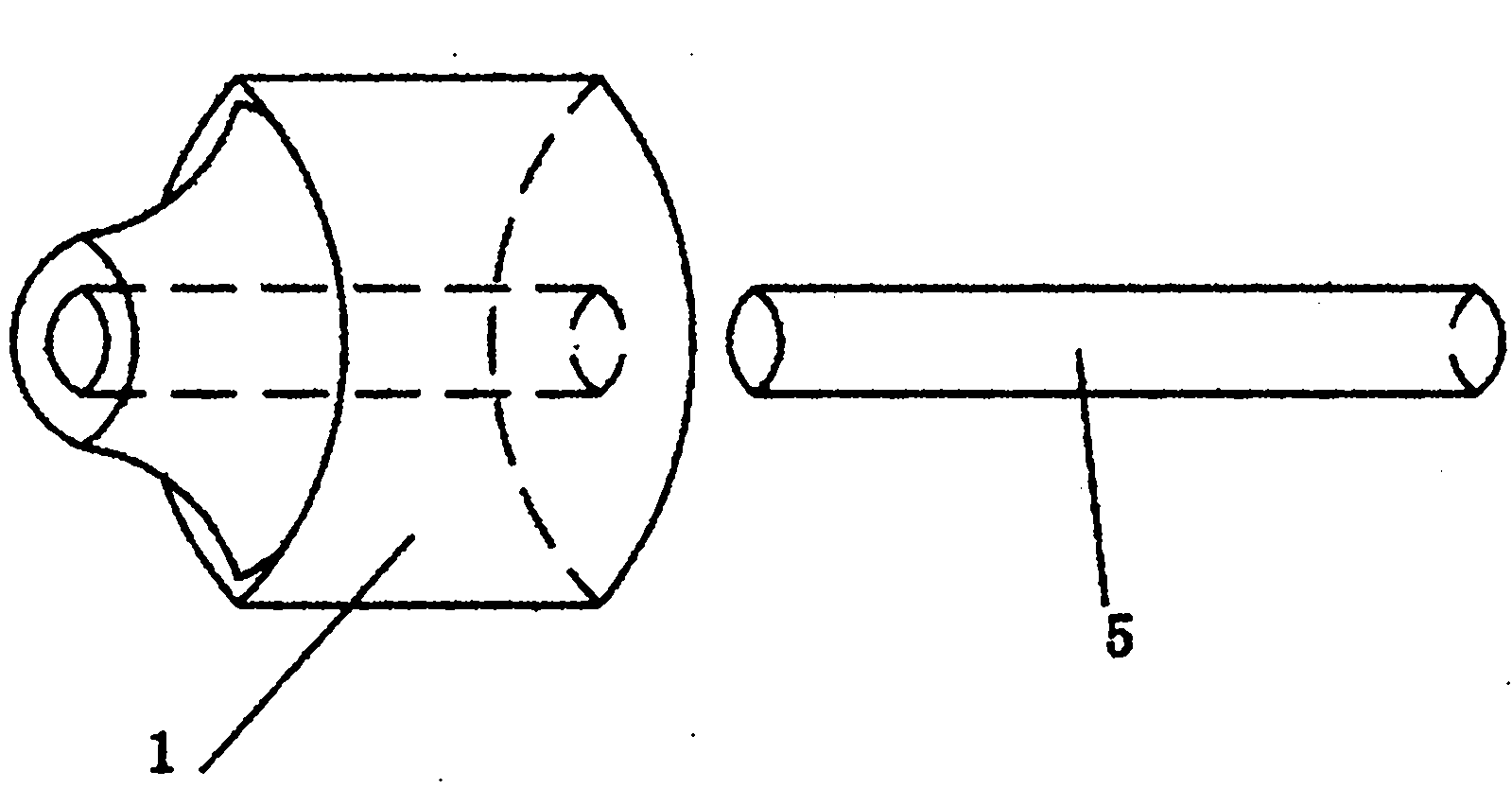

[0013] The present invention adopts the mode that the circle radius gradually decreases from one flat end to the tip, when the steel pipe is inserted into the sealing ring 1 for stamping ( figure 2 , in the picture: stainless steel pipe 5), due to the small radius of the tip, when the pressure is applied, the circle will shrink, and the steel pipe will be wrapped more tightly, ensuring the tightness of the sealing ring and making the hydrostatic test more efficient. high.

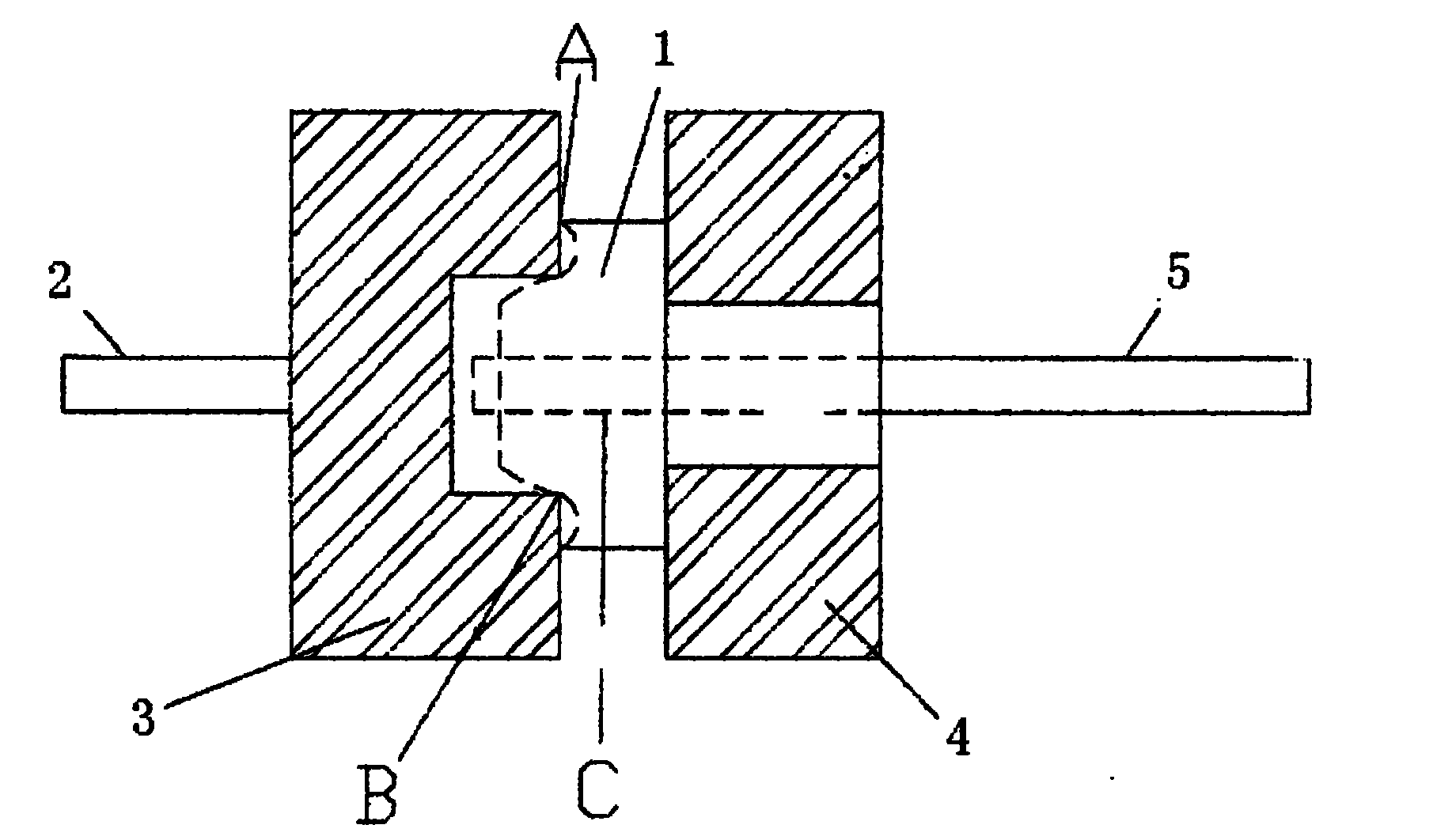

[0014] Depend on image 3 Visible: C refers to the stainless steel pipe 5 and the contact surface of the seal ring 1, and simultaneously under the thrust of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com