Heat dissipating device of electric welding machine

A heat dissipation device and electric welding machine technology, which is applied in the direction of household refrigeration devices, auxiliary devices, applications, etc., can solve the problems of complex air-cooled heat dissipation structure, affecting the service effect and life of the radiator, and easy dust accumulation at the joints of components, etc., to achieve Solve the complex structure of air cooling and heat dissipation, improve the effect of use and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

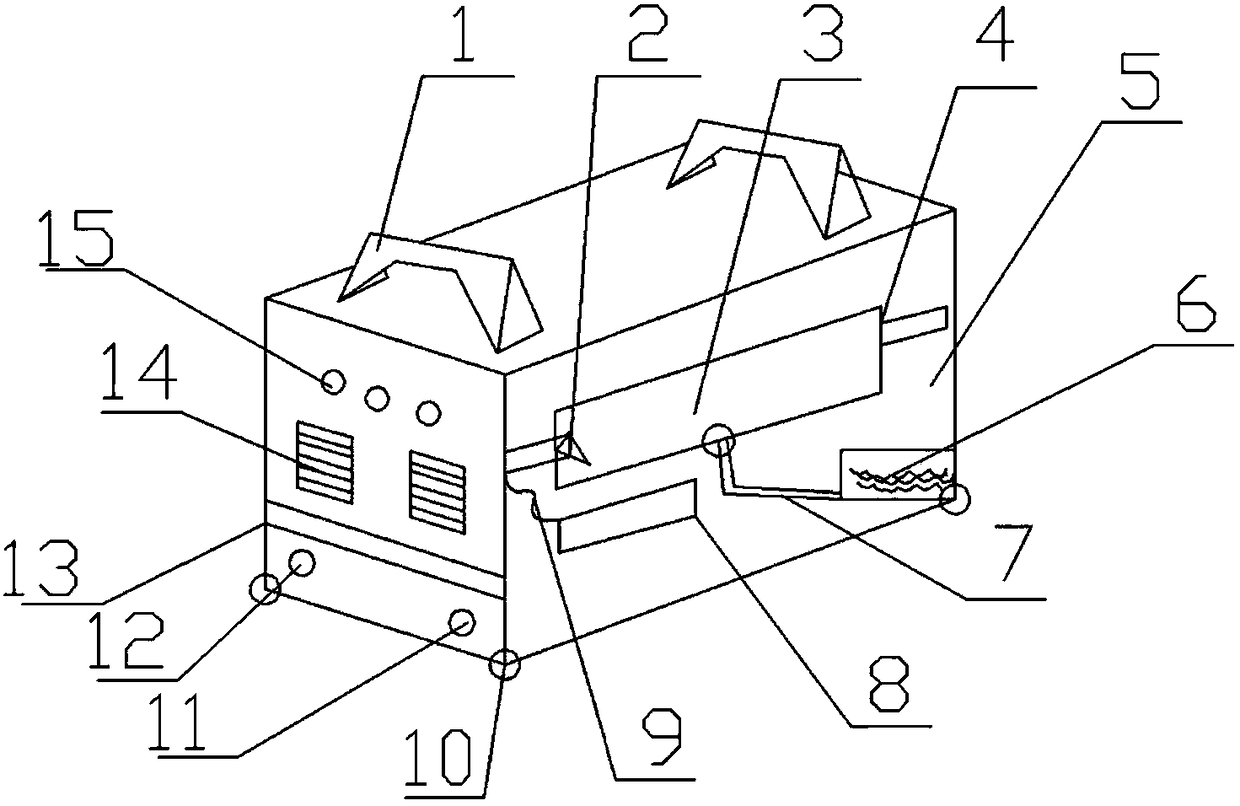

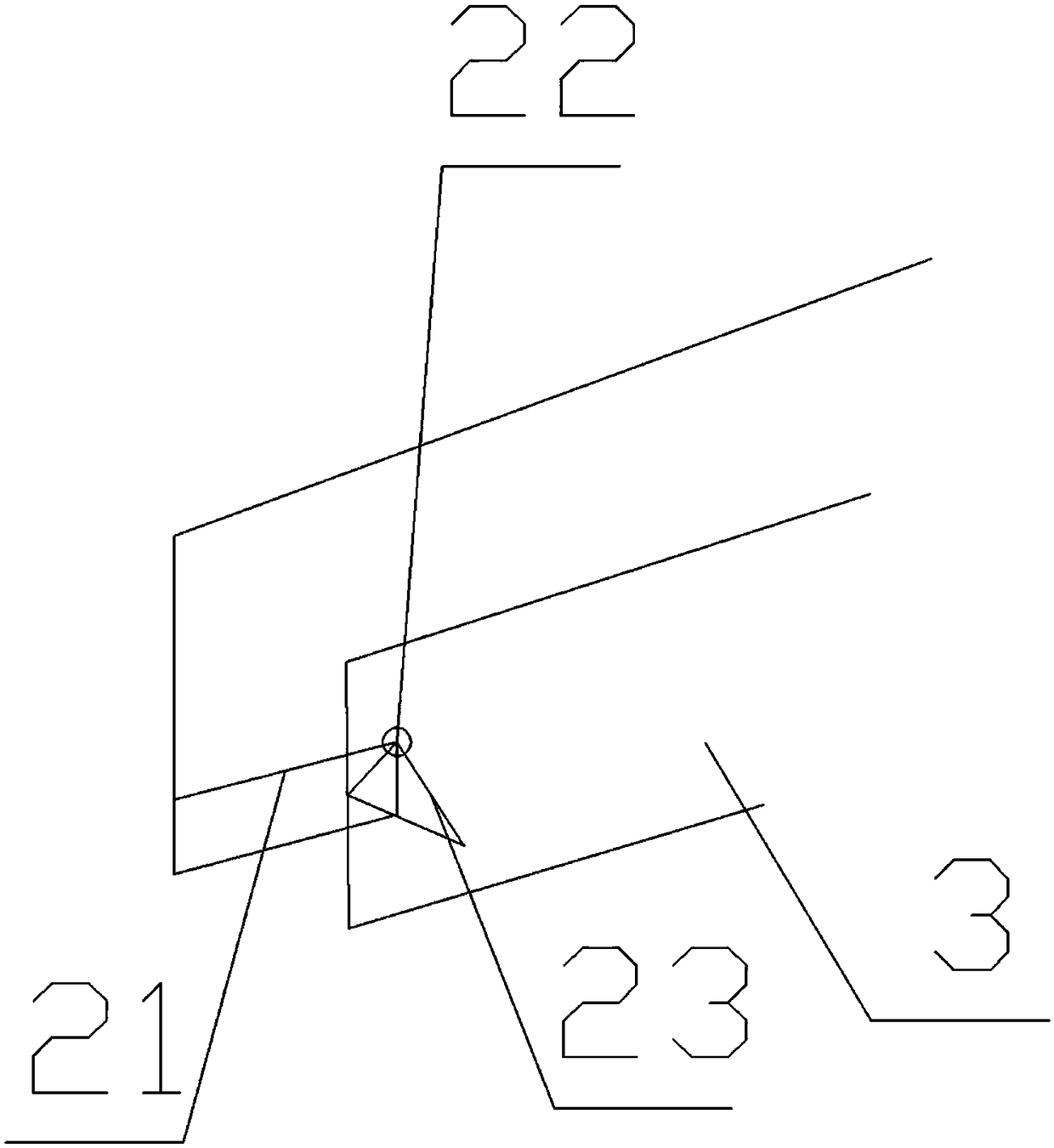

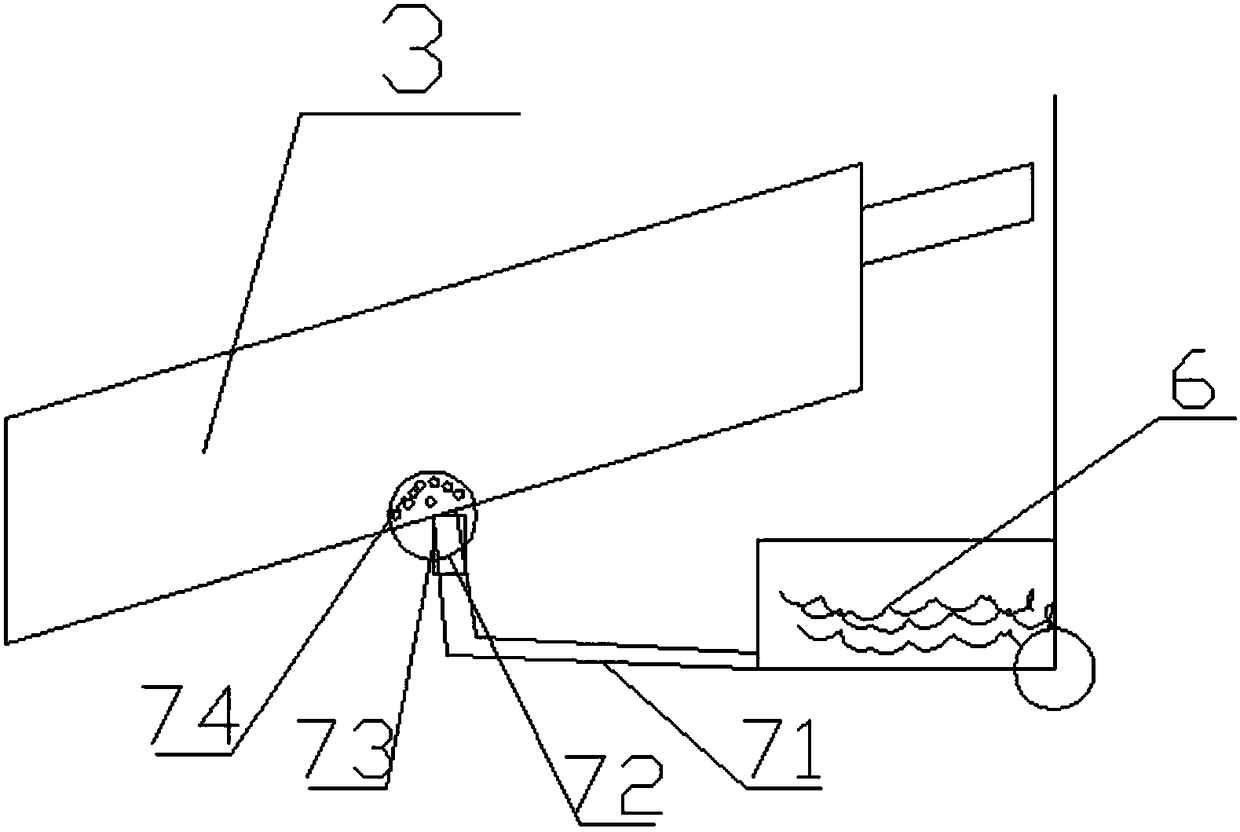

[0020] as attached figure 1 to attach image 3 shown

[0021] The invention provides a heat dissipation device for an electric welding machine, which is characterized in that the heat dissipation device for an electric welding machine includes a handle 1, a slider 2, a heat dissipation pipe 3, a heating element 4, a casing 5, a cold water tank 6, and a water vapor inlet pipe device 7 , slider motor 8, slider motor connecting wire 9, scroll wheel 10, electric welding machine positive current 11, electric welding machine negative current 12, plastic seal 13, heat dissipation port 14 and switch control key 15, and the bottom of the handle 1 is provided with Slider 2, the slider 2 is connected to the radiating pipe 3, the radiating pipe 3 is connected to the heating element 4, the lower part of the heating element 4 is provided with a cold water tank 6, and the cold water tank 6 is connected with water vapor The tube devices 7 are connected to each other, and the left side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com