A high temperature resistant filter cloth

A high temperature resistant, filter cloth technology, applied in filtration and separation, fabric, textile and other directions, can solve the problems of poor temperature resistance of glass fiber, shorten the working effect and life of filter cloth, etc., achieve strong high temperature resistance performance, improve the use effect and effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

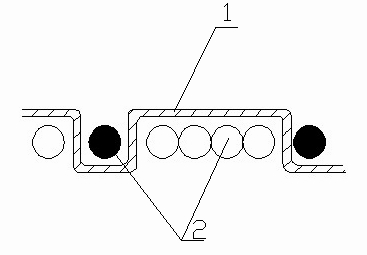

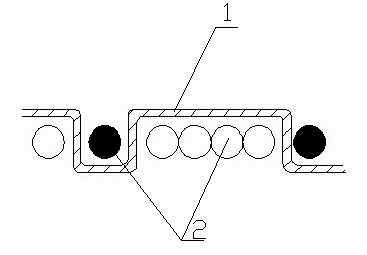

[0009] A high-temperature-resistant filter cloth, which is woven from warp 1 and weft 2, the warp 1 and weft 2 are made of 20s / 2 aramid single yarn, and the warp 1 and weft 2 are woven into 5 / 2 warp satin weave structure.

[0010] The reason why strands are used is that the aramid single yarn does not have strong and weak twists, and the cloth surface has a better style; the other is that the warping is easy to unwind in the axial direction.

[0011] According to the theoretical calculation strength, the warp strength is 1215N, and the weft strength is 878N. The heat shrinkage of the filter cloth in the warp and weft is below 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com