Optical detection device and detection method

A technology of optical detection and detection device, which is applied in the field of optical detection, can solve the problem that the collimator cannot generate a target with a limited distance, and achieve the effect of a reliable measuring instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

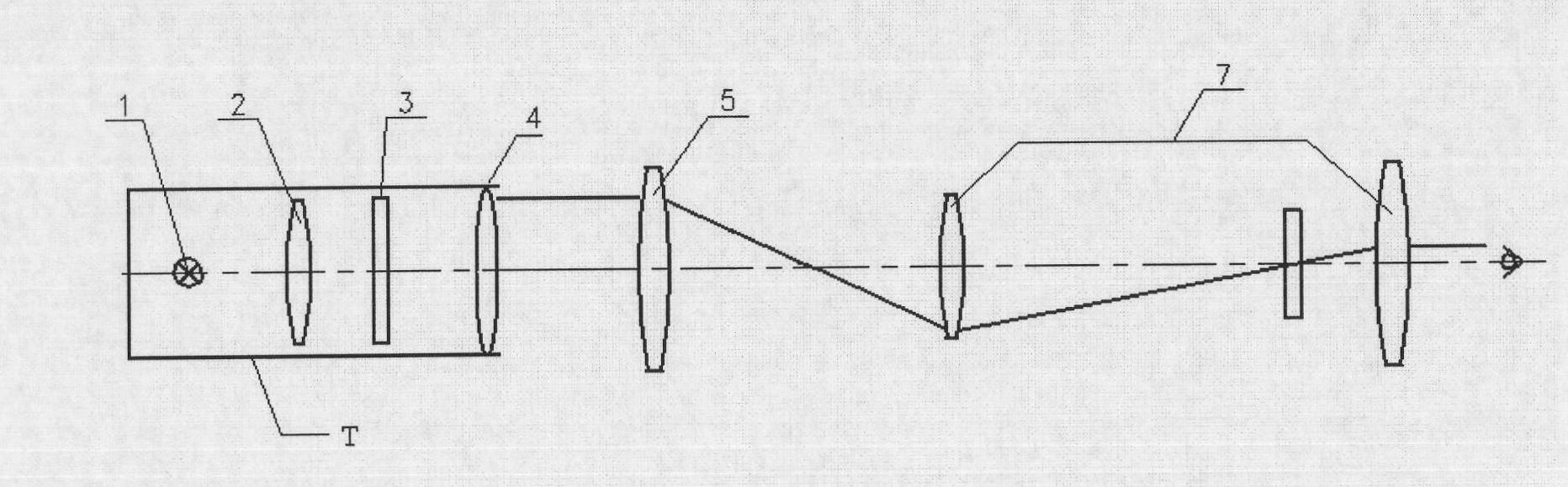

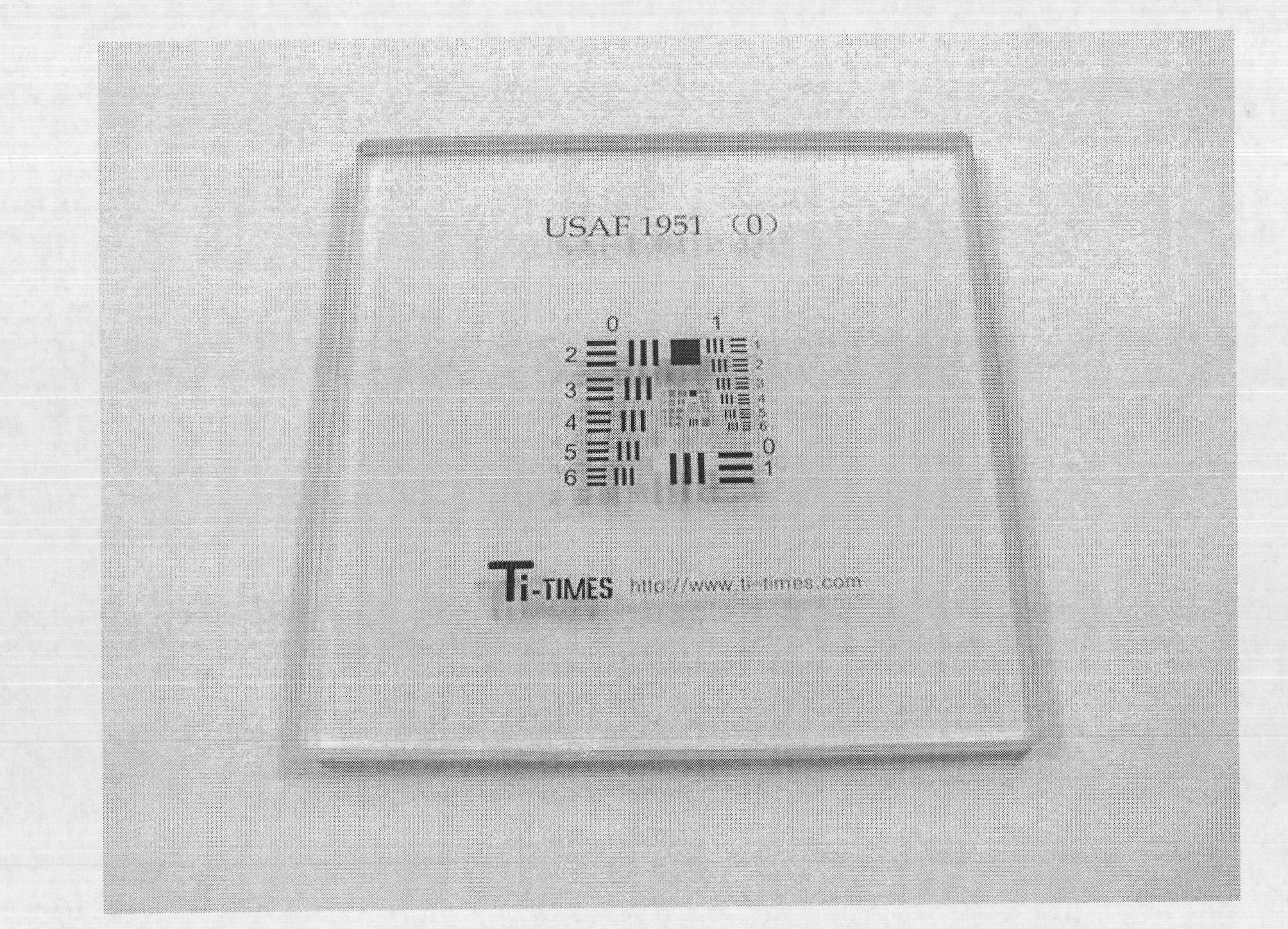

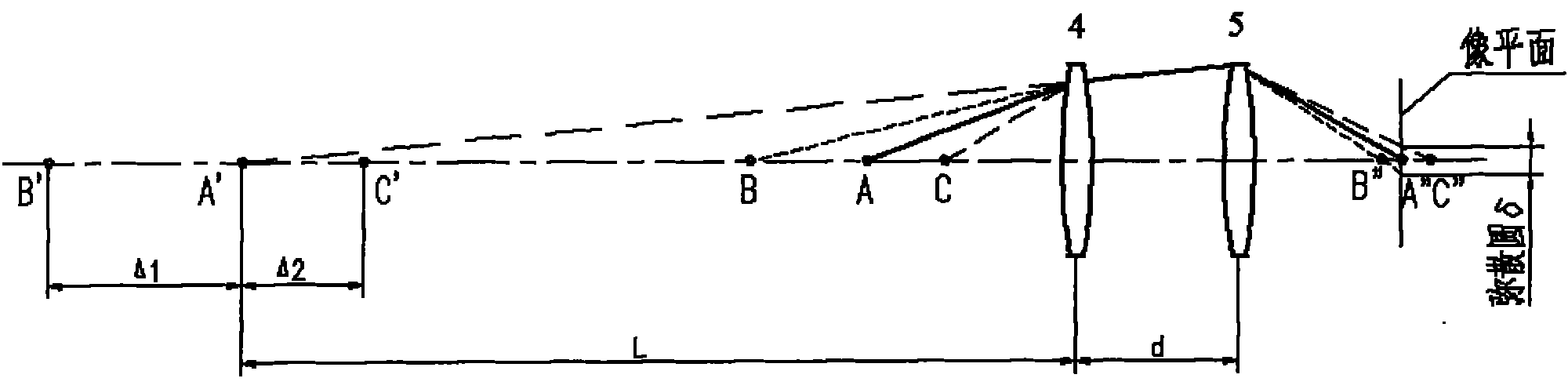

[0033] like Figure 4 As shown, the depth of field detection device of the present invention is composed of guide rail group g1, illuminator group g2, resolution plate group g3, collimator mirror group g4, lens mount group g5, measuring microscope group g6, and slide seat group g7. The guide rail group g1 is the base of the detection device, on which are set the resolution plate group g3 and the collimator mirror group g4, the resolution board group g3 can move relative to the collimator mirror group g4, the resolution board group g3 and the collimator mirror group g4 It is used to generate the imaging target of the inspected lens, that is, an object formed at a limited distance from the inspected lens. A measuring microscope group g6 is installed on the guide rail group, and the measuring microscope is used to perform resolution detection on the inspected lens. A lens mount group g5 is arranged between the collimating lens group g4 and the measuring microscope group g6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com