Barrier type silicon-based thin film semi-laminated solar cell

A technology of silicon-based thin film and stacked sun, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing current, difficult selection of intermediate layers, and increasing spectrum absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

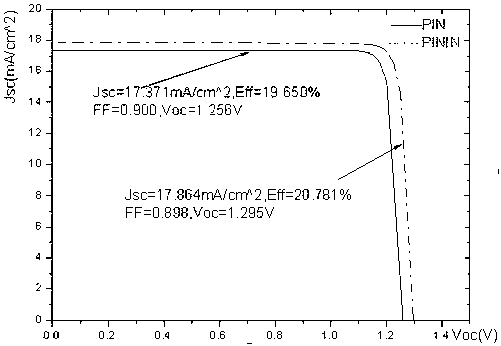

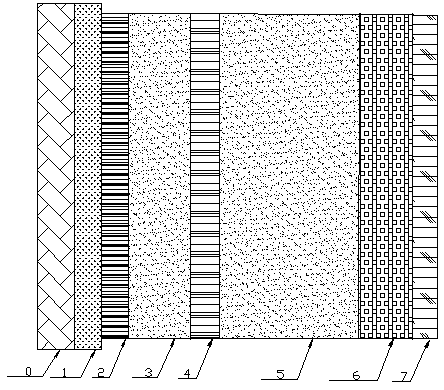

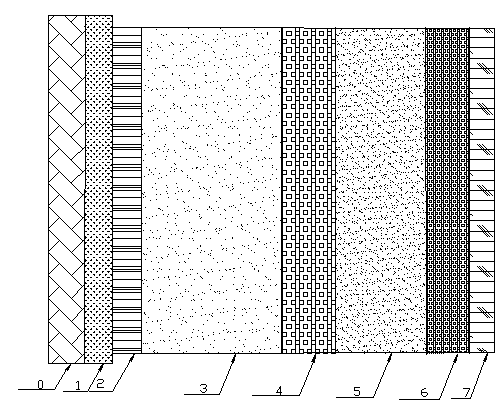

[0026] 1. Structural design of solar cells

[0027] Deposition of P on a transparent glass substrate 2 I 2 P 1 I 1 N 1 and P 1 I 1 N 1 I 2 N 2 Barrier type semi-stacked thin film solar cells with structure, where P 2 I 2 P 1 I 1 N 1 and P 1 I 1 N 1 I 2 N 2 The optical bandgap Eg of each layer in the P 2 I 2 P 1 I 1 N 1 structure, P 2 The doping concentration is taken as 3.0×10 19 cm -3 , Eg=1.96eV, I 2 Eg=1.8eV, P 1 The doping concentration is 3.0×10 17 cm -3 , Eg=1.96eV, I 1 Eg=1.7eV, N 1 The doping concentration is 3.0×10 19 cm -3 , Eg=1.6eV, at P 1 I 1 N 1 I 2 N 2 structure, P 1 The doping concentration is taken as 3.0×10 19 cm -3 , Eg=1.96eV, I 1 Eg=1.8eV, N 1 The doping concentration is 3.0×10 17 cm -3 , Eg=1.75eV, I 2 Eg=1.7eV, N 2 The doping concentration is 3.0×10 19 cm -3 , Eg=1.6eV, the band gap of each layer decreases in turn, which is conducive to the full absorption of the solar spectrum, thereby improving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com