Equipment and method for assembling storage battery

An assembly method and technology for assembling equipment, which are applied in battery pack components, secondary battery manufacturing, circuits, etc., can solve problems such as poor battery quality, complicated manufacturing processes, and battery failures, improve consistency, production efficiency, and streamline The effect of butt welding and cap test procedures to avoid human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

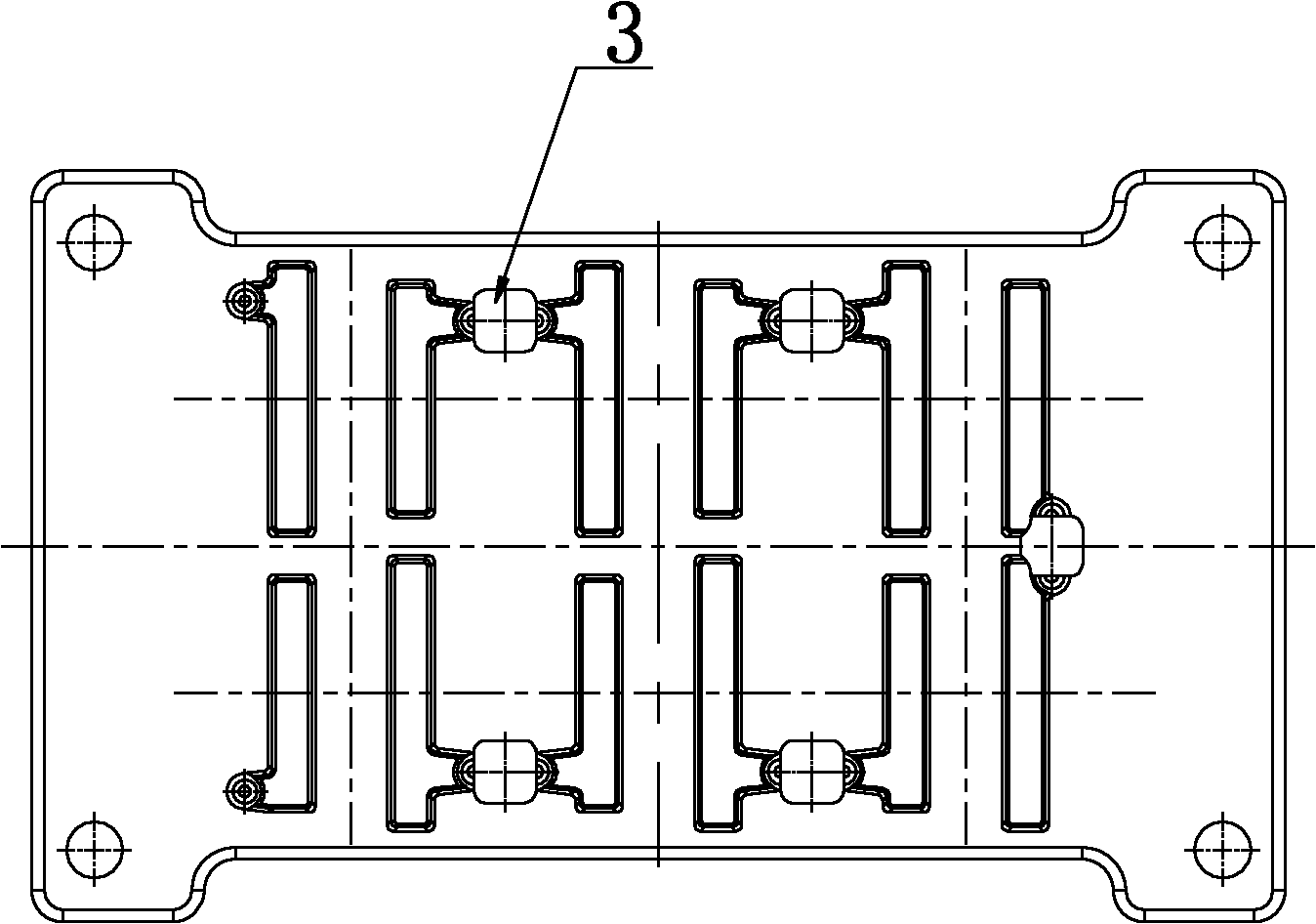

[0045] An embodiment of a storage battery assembly device disclosed in the present invention includes a pole group welding butt welding mold 1 and a tooling integration equipment 2, wherein the pole group welding butt welding mold includes a casting and welding mold box 11 for Load the paired pole group;

[0046] The pole group welding butt welding mold also includes a welding casting-butt welding bottom mold 12 for spraying a release agent in its cavity;

[0047] Described welding casting-butt welding bottom mold 12 is also used for filling lead therein after heating;

[0048] The pole group welding butt welding mold also includes a scraper for scraping off excess lead in the welding casting-butt welding bottom mold 12 .

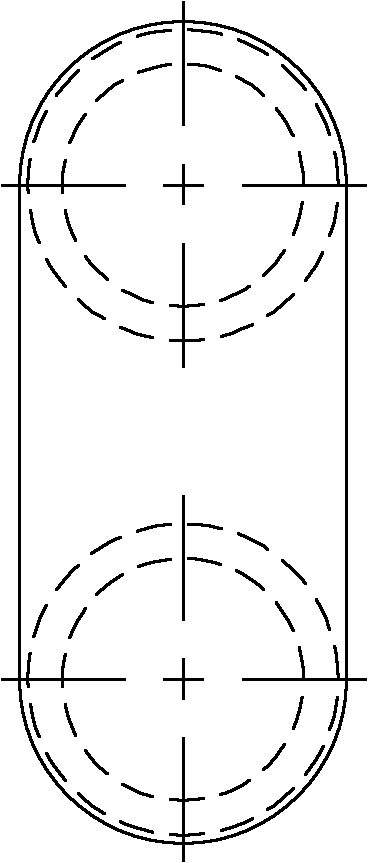

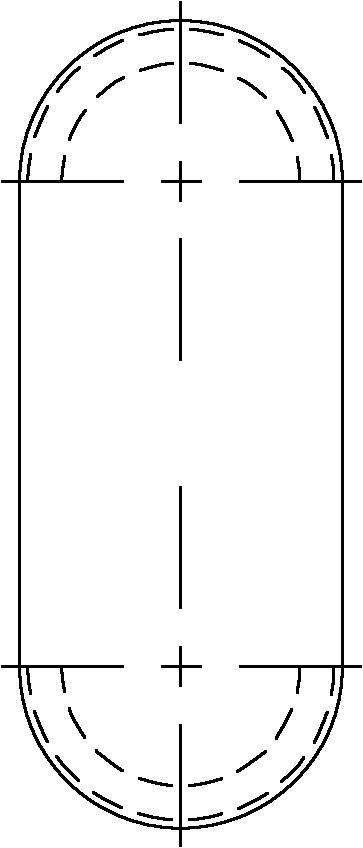

[0049] In an embodiment of the storage battery assembly equipment disclosed in the present invention, the butt welding part 3 of the pole group welding butt welding mold is in a semicircular structure.

[0050] In an embodiment of the battery assembly equ...

Embodiment 2

[0056] The invention discloses a storage battery assembly method, comprising the following steps:

[0057] Extreme group welding and butt welding;

[0058] Demoulding, shelling.

[0059] Wherein, the pole group welding and butt welding are carried out as follows:

[0060] Step 101, put the assembled pole groups into the casting and welding mold box 11, and perform pretreatment before welding.

[0061] The pre-treatment before welding includes cutting ears, brushing ears, and immersion casting flux for matching groups of poles.

[0062] Step 102, spray a release agent in the mold cavity of the cast-butt-weld base mold 12 .

[0063]Step 103, heating the welding cast-butt welding bottom mold 12 sprayed with release agent.

[0064] Step 104, filling the heated cast-butt weld bottom mold 12 with lead.

[0065] Step 105, use a scraper to scrape off excess lead in the cast-butt weld bottom mold 12, and put it on the workbench for cooling.

[0066] Step 106 , after cooling to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com