Air curtain design method for sealing transmission channel in laser

A technology of transmission channel and design method, applied in lasers, laser parts, electrical components, etc., can solve problems such as difficulty in obtaining technical details, achieve stable flow field conditions, increase sealing performance, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

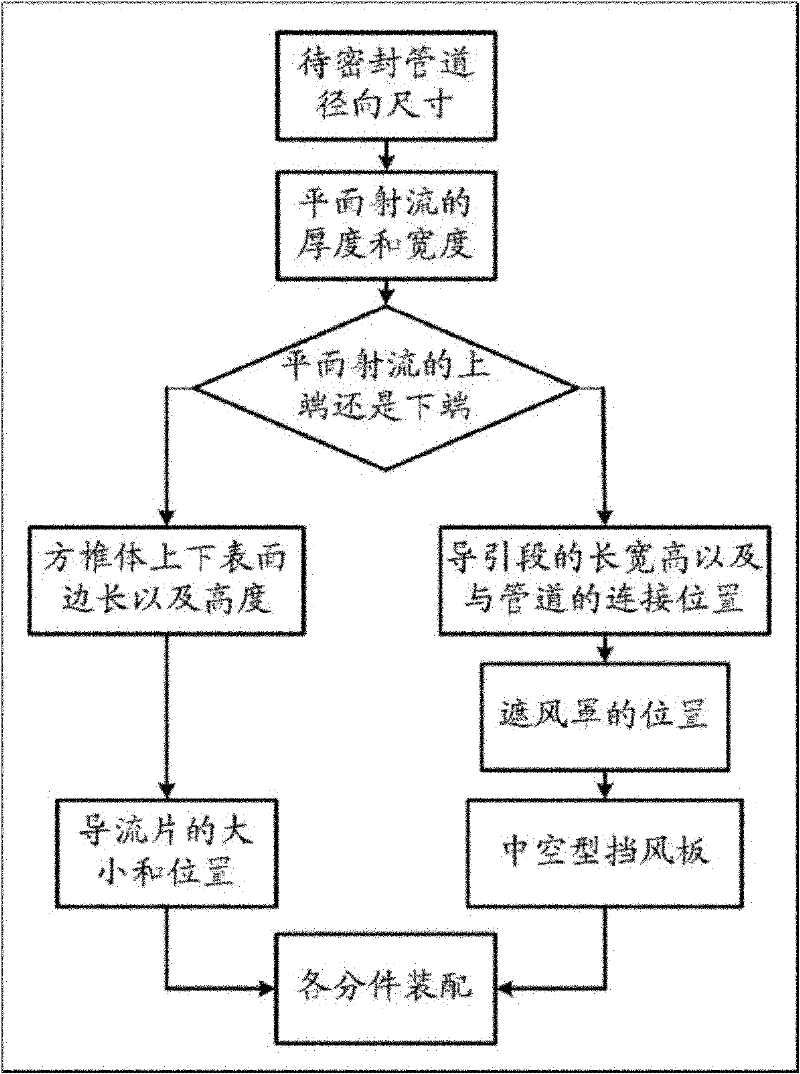

[0038] The specific steps are as figure 1 Shown:

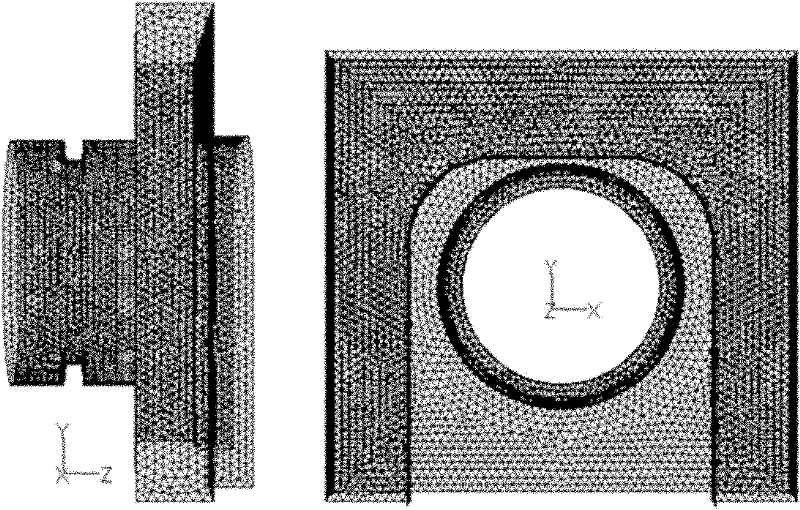

[0039] (1) Structural modeling

[0040] The first step is to determine the thickness b=L / 4=30mm of the plane jet tube according to the diameter L=120mm of the inner transmission channel of the laser. The width of the plane jet tube is taken as: d=1.83*L=220mm.

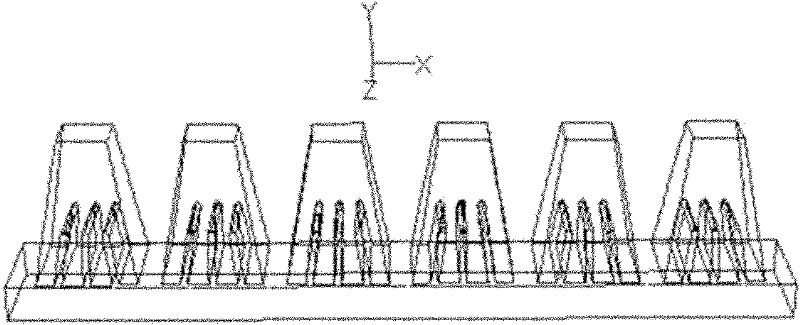

[0041] The second step is to establish a square cone structure, considering matching with the existing gas supply pipeline. The side length of the upper surface is taken as 14mm, the side length of the lower surface is taken as 28mm, and the height is taken as 40mm.

[0042] The third step is to place three deflectors in the square cone. The thickness of the deflector is 1mm, the height is 20mm, the distance between the deflectors is 7mm, and the inclination angle of the deflectors on both sides is θ=arctan(0.16) .

[0043] In the fourth step, the number of square cones is taken as n=6, and the distance between the square cones is 7 mm, and the square cones are place...

Embodiment 2

[0055] The specific steps are as figure 1 Shown:

[0056] (1) Structural modeling

[0057] In the first step, it is first assumed that the diameter of the laser inner transmission channel is L=180mm, and thus the thickness of the plane jet tube is determined as b=L / 4=45mm. The width of the plane jet tube is taken as: d=1.8*L≈330mm.

[0058] The second step is to establish a square pyramid structure. The side length of the upper surface is taken as 21mm, the side length of the lower surface is taken as 42mm, and the height is taken as 60mm.

[0059] The third step is to place three deflectors in the square cone. The thickness of the deflector is 1.5mm, the height is 30mm, the distance between the deflectors is 10.5mm, and the inclination angle of the deflectors on both sides is θ≈arctan( 0.16).

[0060] In the fourth step, the number of square cones is taken as n=6, and the distance between the square cones is 10.5mm, and the square cones are placed symmetrically and evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com