Magnetization method and magnetization component of permanent magnet motor

A magnetization method and technology of permanent magnet motor, which are applied in the direction of magnetic circuit rotating parts, magnetic circuit static parts, magnetic circuit shape/style/structure, etc. The effect of avoiding safety hazards, simple assembly and low power supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

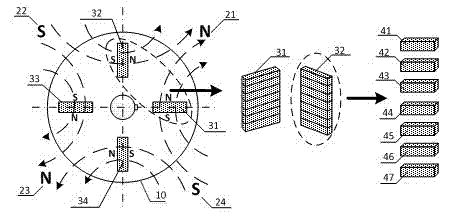

[0037] The first embodiment concerns the fabrication and composition of the magnetizing assembly.

[0038] The magnetizing assembly mainly includes two parts: an unmagnetized permanent magnet and a coil, wherein the unmagnetized permanent magnet is processed into a desired shape by an unmagnetized permanent magnet block, and Fig. 5 (a) shows that the magnetizing assembly 141, 142 has been installed on the Situation on the permanent magnet motor rotor 170; Fig. 5 (b) has shown a kind of method that the non-magnetized permanent magnet 150 and the magnetized coil 160 are assembled into the magnetized assembly, and its method is that the coil 160 is directly set to the non-magnetized permanent magnet. on the magnet 150.

[0039] Fig. 5 (c) shows that the magnetizing assembly 142 is made of an unmagnetized permanent magnet 150 and a coil 160, wherein the cuboid unmagnetized permanent magnet 150 is bonded by 6 unmagnetized permanent magnet blocks 151 to 156, and the coil 160 is Acc...

no. 2 example

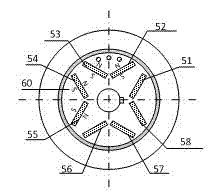

[0041] Figure 6 Taking the permanent magnet motor with the permanent magnet on the inner rotor as an example, when the permanent magnet is located on the internal moving parts of the motor in the present invention, a method for installing and magnetizing the permanent magnet motor is described. The installation and magnetizing method is first Install the magnetizing components 201 to 206 into the corresponding slots of the permanent magnet motor rotor 210 without components installed, and assemble the complete rotor 220, then assemble the permanent magnet motor stator 230 and the rotor 220, and use the support 250 to support the rotor 220, and then the magnetizing coils of the magnetizing components 201 to 206 are connected to the magnetizing power supply 240 after being connected in series, the power supply is discharged, and the magnetizing coils generate a magnetizing magnetic field to realize the magnetization of unmagnetized permanent magnets into permanent magnets. Fina...

no. 3 example

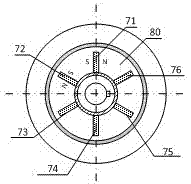

[0043] Figure 7 Taking the permanent magnet motor with the permanent magnet on the outer rotor as an example, when the permanent magnet is located on the external moving parts of the motor in the present invention, a method for installing and magnetizing the permanent magnet motor is described. The installation and magnetizing method is first Install each magnetizing assembly 300 to 309 into the corresponding slot of the permanent magnet motor outer rotor 310 without assembly, assemble to obtain a complete outer rotor 320, and then assemble the end cover 340, the permanent magnet motor stator 330 and the outer rotor 320 together , so as to complete the assembly of the entire motor 350, and then connect the magnetizing coils of the magnetizing components 300 to 309 in series to the magnetizing power supply 360, the power supply is discharged, and the magnetizing coils generate a magnetizing magnetic field to realize the magnetization of the unmagnetized permanent magnet for pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com