Multiwinding series connection variable volume induction motor and control device thereof

A technology of induction motor and control device, applied in the direction of AC motor control, asynchronous induction motor, electromechanical device, etc., can solve the problems of low efficiency and power factor, little improvement, complicated control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

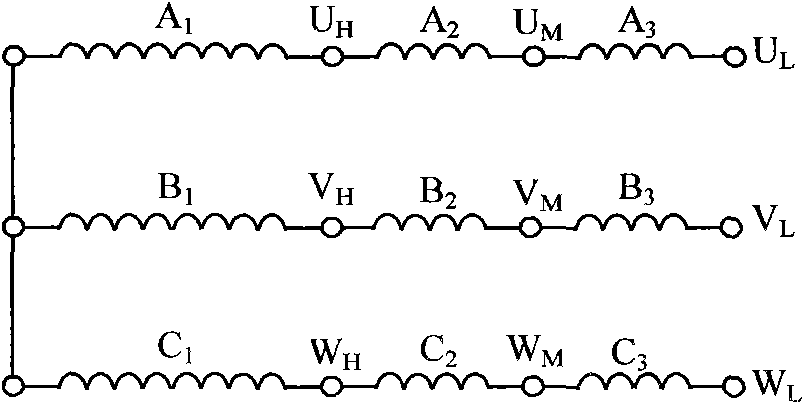

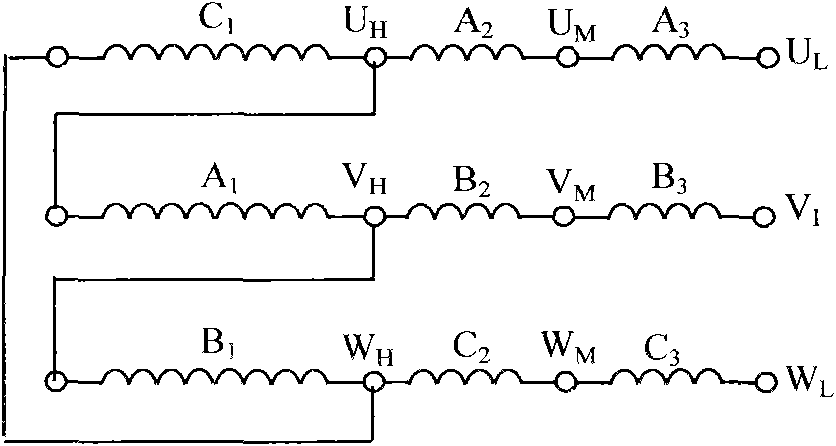

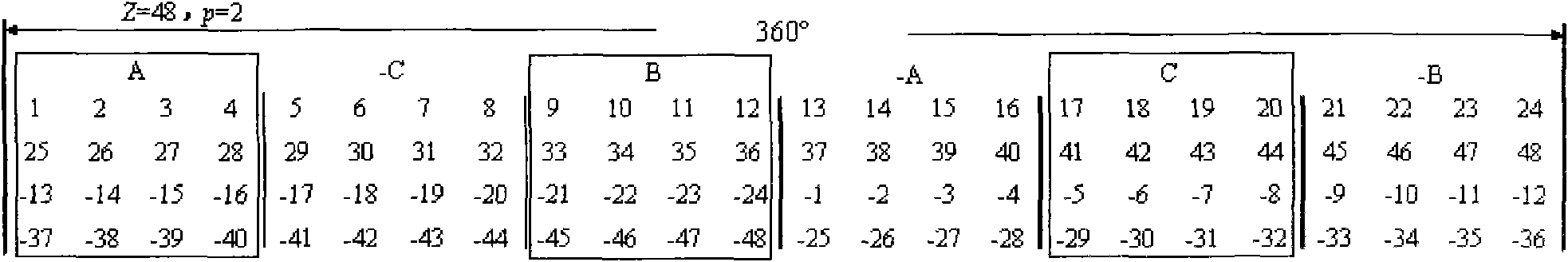

[0021] Such as figure 1 In the multi-winding series variable capacity induction motor shown, the stator winding of this motor is composed of three sets of three-phase windings, and the corresponding phases of the three sets of windings are connected in series, and the following subscripts are respectively "A1, B1, C1; A2, B2, C2 ; A3, B3, C3" are distinguished, each phase winding has 3 outlets, and there are 9 outlets in three phases, and the 9 outlets are respectively "UH, VH, WH" and "UM, VM, WM" and "UL, VL, WL" are distinguished, and the subscripts "H" and "M" and "L" represent high, medium and low capacity levels respectively. The three-phase power is connected from the outlet terminals "UH, VH, WH". At this time, the three-phase winding is Y-connected, corresponding to high-capacity gear; the three-phase power supply is connected from the outlet terminals "UM, VM, WM". At this time, the three-phase winding is Y-connected, which corresponds to the medium-capacity gear; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com