Multiple-motor control circuit with link arm bridge

A technology of multiple motors and control circuits, which is applied in the direction of controlling multiple DC motors, etc., to achieve the effect of reducing cost and volume and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

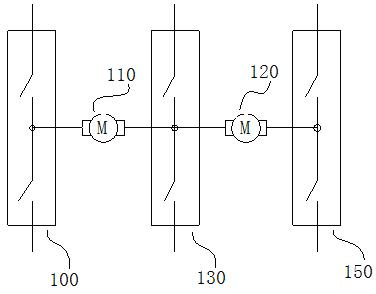

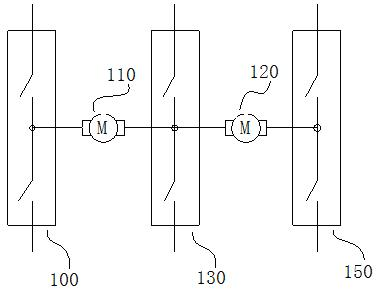

[0017] figure 1 It is a block diagram of multi-motor control circuit with link bridge driving 2 motors.

[0018] The half-bridge switching drive circuit 100 is composed of two electronic switches. These two electronic switches can select the appropriate electronic device according to the voltage, power, PWM frequency required by the application. One end of the bridge arm is connected to the positive power supply, and each bridge arm can share the same power supply. The other end of the bridge arm is connected to ground or a negative supply. Other bridge arms are similar. When the DC motor 110 is required to run, the half-bridge switching drive circuit 100 and the half-bridge switching drive circuit 130 are combined to form a bridge circuit to control its rotation direction and speed, and the half-bridge switching drive circuit 150 is turned off at the same time. When the DC motor 120 is required to run, the half-bridge switching drive circuit 100 and the half-bridge switc...

Embodiment 2

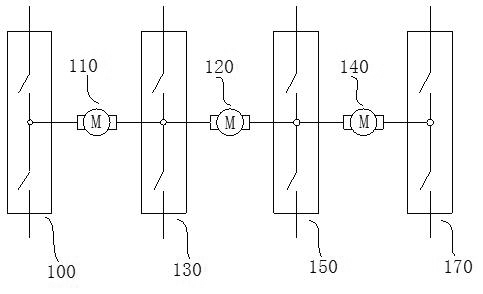

[0020] figure 2 It is a block diagram of multi-motor control circuit with link bridge driving 3 motors.

[0021] The figure includes a half-bridge switching drive circuit 100 ; a half-bridge switching drive circuit 130 ; a half-bridge switching drive circuit 150 ; a brushed DC motor 110 ; a brushed DC motor 120 ; and a brushed DC motor 140 . When the DC motor 110 is required to run, the half-bridge switch drive circuit 100 and the half-bridge switch drive circuit 130 are combined to form a bridge circuit to control its rotation direction and speed, and at the same time, other half-bridge switch drive circuits are turned off. When the DC motor 120 is required to run, the half-bridge switch drive circuit 100 and the half-bridge switch drive circuit 150 are combined to form a bridge circuit to control its rotation direction and speed, and the other half-bridge switch drive circuits 130 are turned off at the same time. When the DC motor 140 is required to run, the half-bridge sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com