Suction filtration/concentration method and suction filtration/concentration device

The technology of a concentration device and a concentration tank is applied in the directions of loose filter material filter, filtration separation, filtration treatment, etc., which can solve the problems of weak adhesion strength, no shape retention of concentrated sludge, and low concentration of concentrated sludge. To achieve the effect of preventing re-dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0120] In order to confirm the effect of the present invention, the present inventors conducted a siphon-type suction filtration concentration test using a filter cloth with the sludge of a water purification plant as a target for filtration and concentration, and used the peeling pressure obtained by using water as a peeling medium as a parameter. The relationship between time and peel rate was investigated.

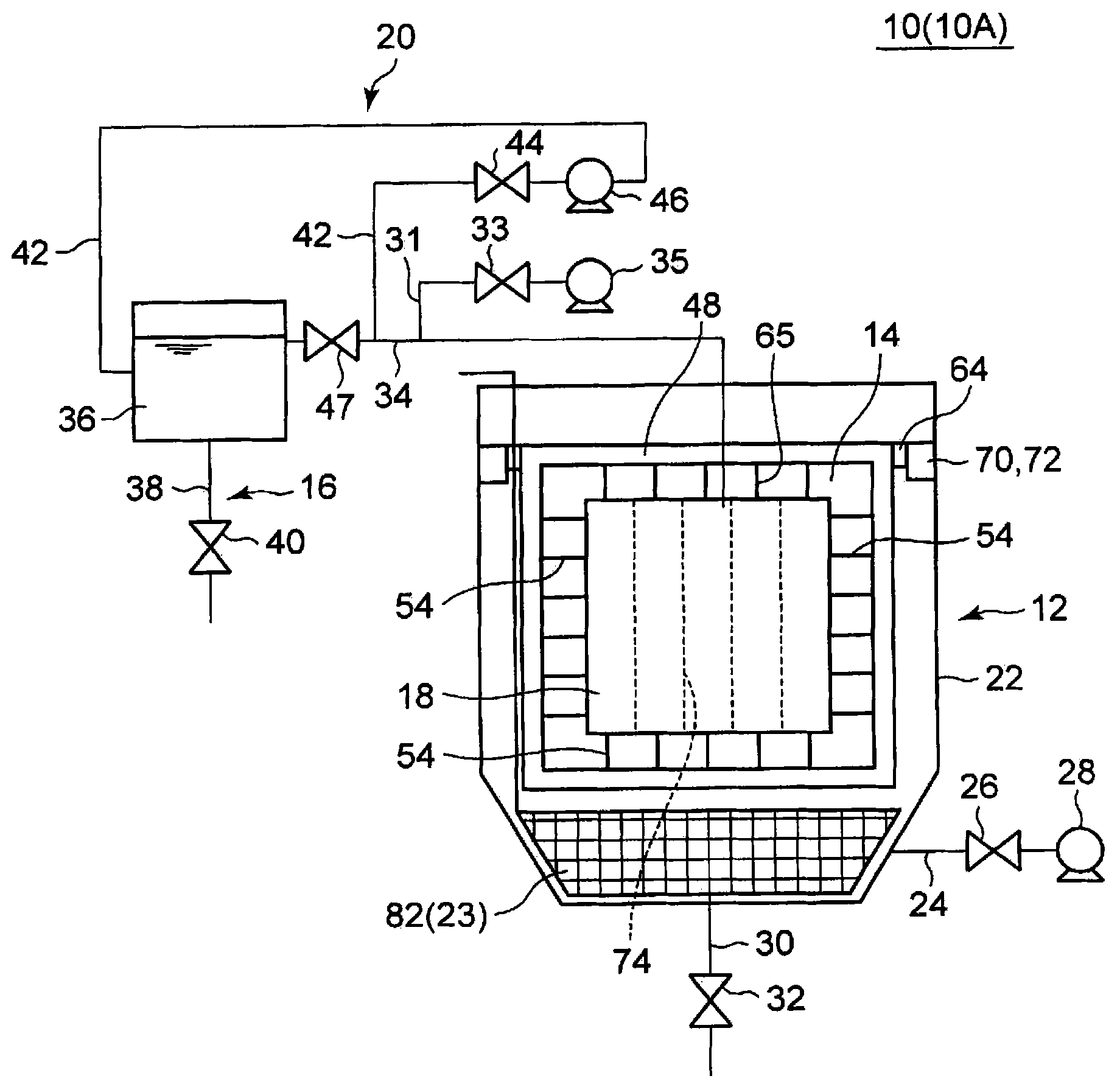

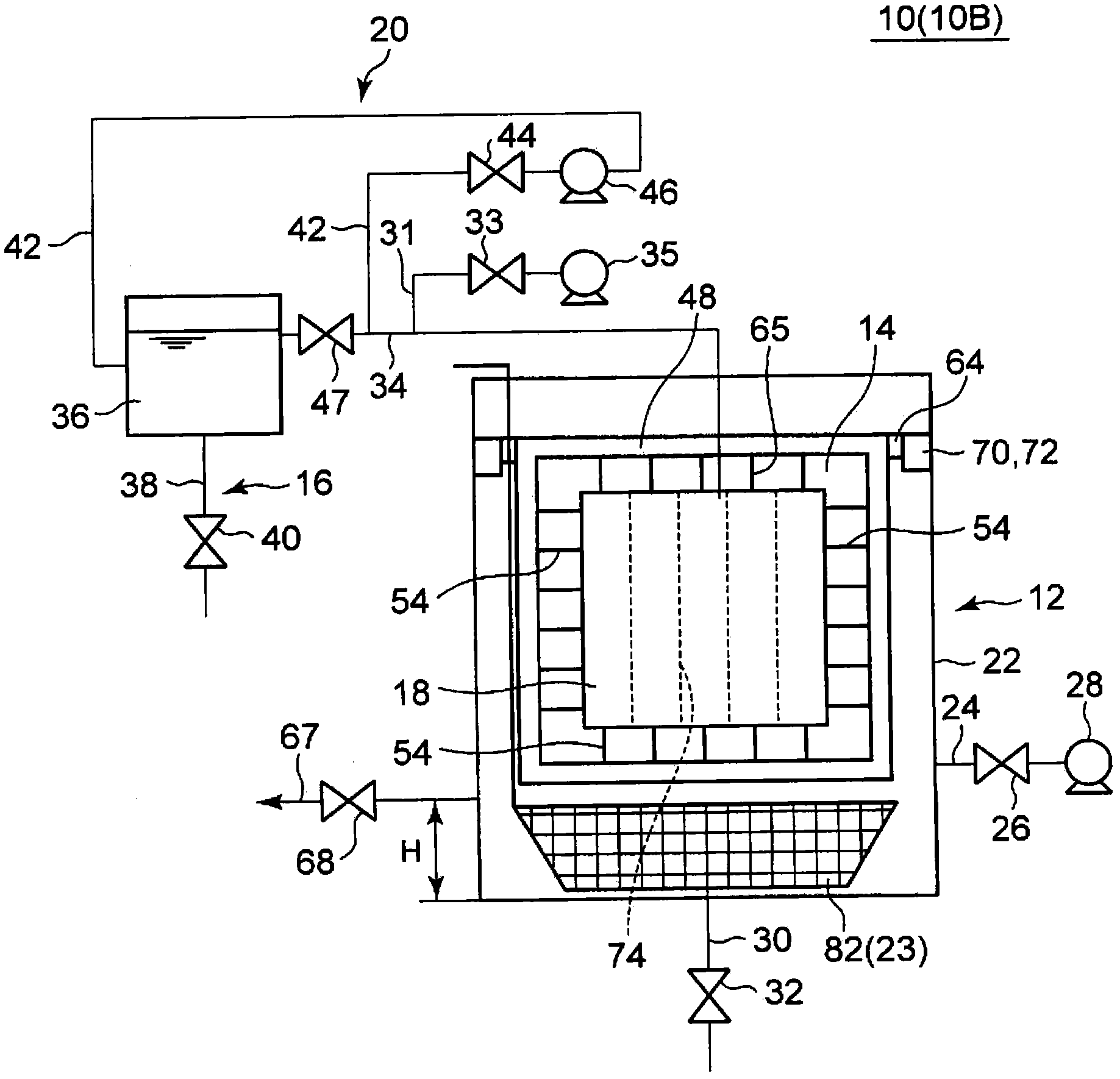

[0121] Figure 12 Indicates the entire test apparatus. Due to the basic structure and the Figure 2A The structure after removing the concentrated sludge scooping part 23 (mesh tray 82 ) is the same, so the detailed description thereof is omitted, but the water inflow pipe 42 is connected in the middle of the inverted U-shaped pipe whose one end communicates with the filter chamber 76 . 42 is provided with a peeling pressure regulating valve 150, and by adjusting the opening degree of the peeling pressure regulating valve 150, the pressure of water and the supply time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com