Tobacco stem polishing machine

A polishing machine and tobacco stem technology, applied in tobacco, tobacco processing, application, etc., can solve problems affecting the quality of tobacco stem products, pollution of the working environment, and inability to control quality, so as to achieve smooth material passages and dust distribution passages, and ensure cleanliness Hygienic, structurally simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

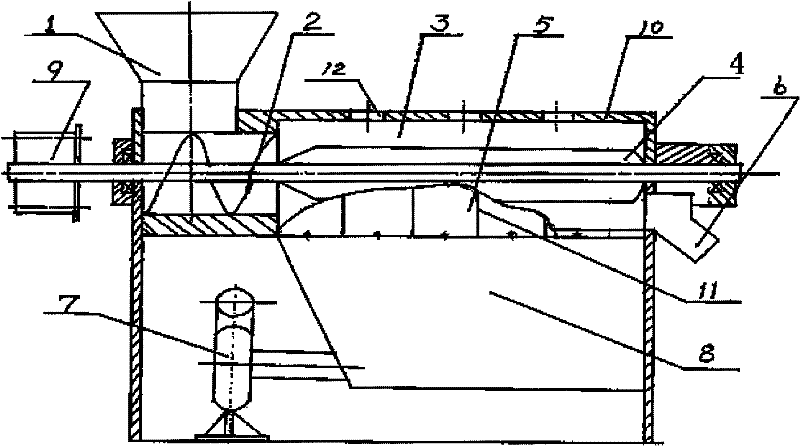

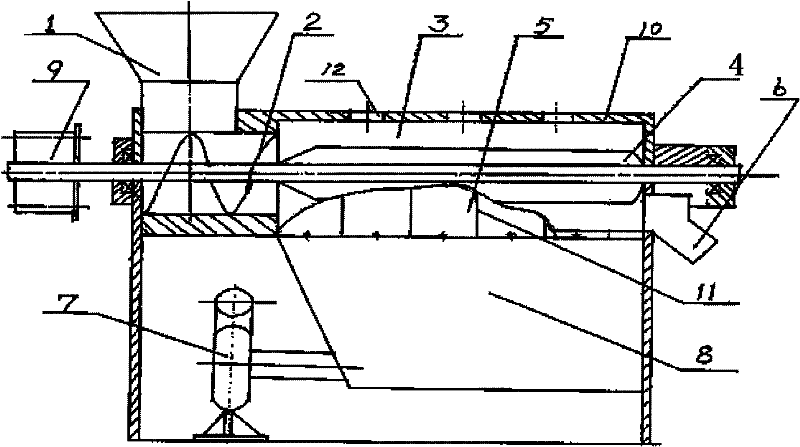

[0023] A tobacco stem polishing machine, comprising a frame on which a material pusher 2 and a polishing chamber 3 are mounted, the material pusher 2 is located at the feeding end of the polishing chamber 3, and the material pusher 2 and the polishing chamber 3 have mutual Unicom channel, the upper end of the material propeller 2 is provided with a hopper 1, and a spiral propulsion shaft is installed in the material propeller 2, and the polishing chamber 3 is composed of a cavity surrounded by an upper cover plate 10 and a lower dust sieve plate 5 , the cover plate 5 is provided with three convex ribs and three air inlets 12, and the air inlets 12 are respectively provided with regulating dampers, the dust sieve plate 5 is a semicircular mesh plate with holes, and is fixed on the The lower part of the polishing chamber 3 is provided with a sealed chamber 8 under the dust sieve plate 5, the dust removal fan 7 is connected outside the sealed chamber 8, and the polishing roller 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com