Quick assembling and disassembling heat-preserving device for christmas tree

A technology of thermal insulation device and Christmas tree, which is applied to isolation devices, earthwork drilling, wellbore/well components, etc., can solve the problems of multiple thermal insulation dead corners, waste of maintenance and maintenance costs, and difficulty in disassembly, so as to shorten the disassembly and assembly of thermal insulation devices. time, good internal and external sealing, and the effect of economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

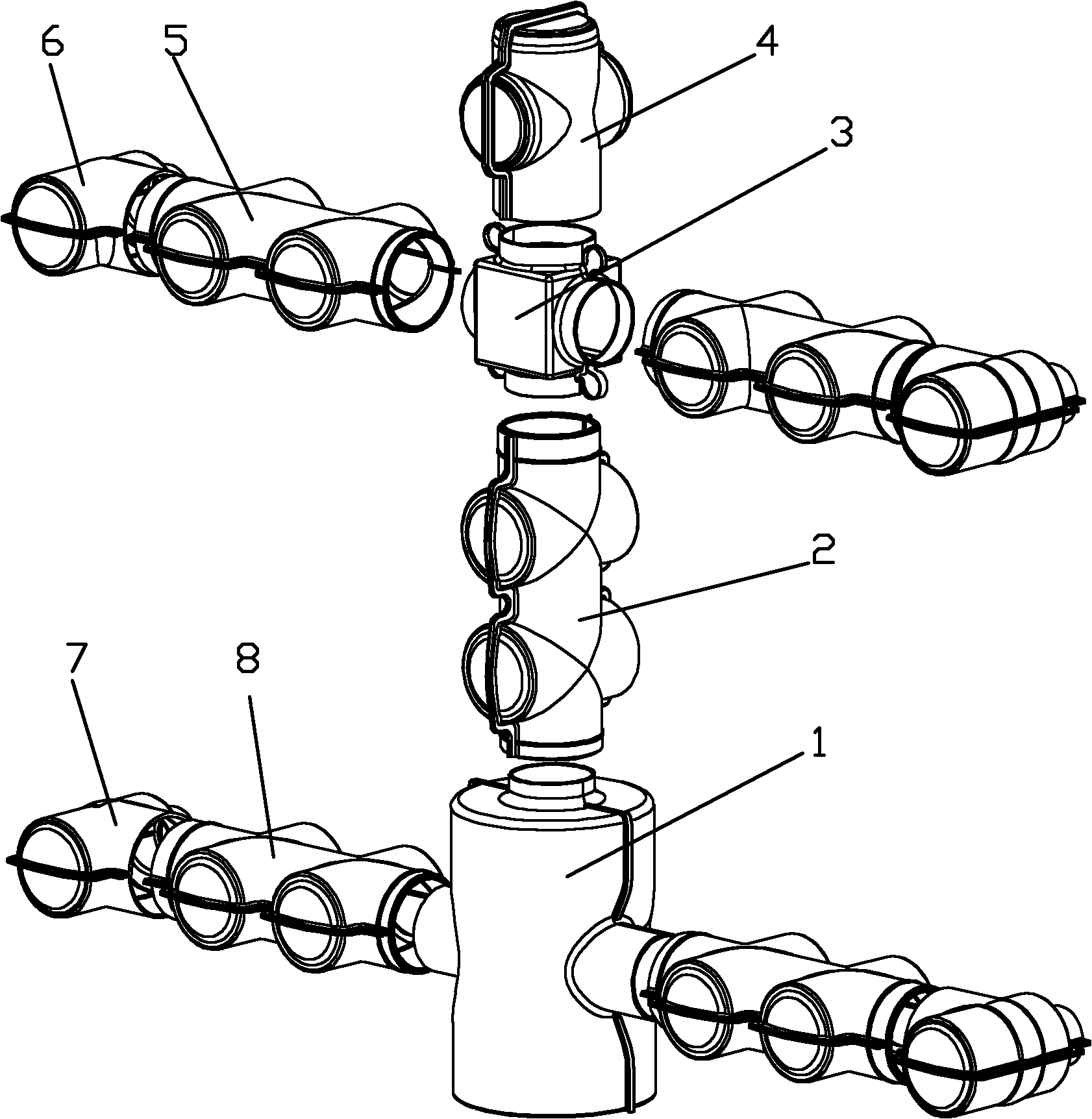

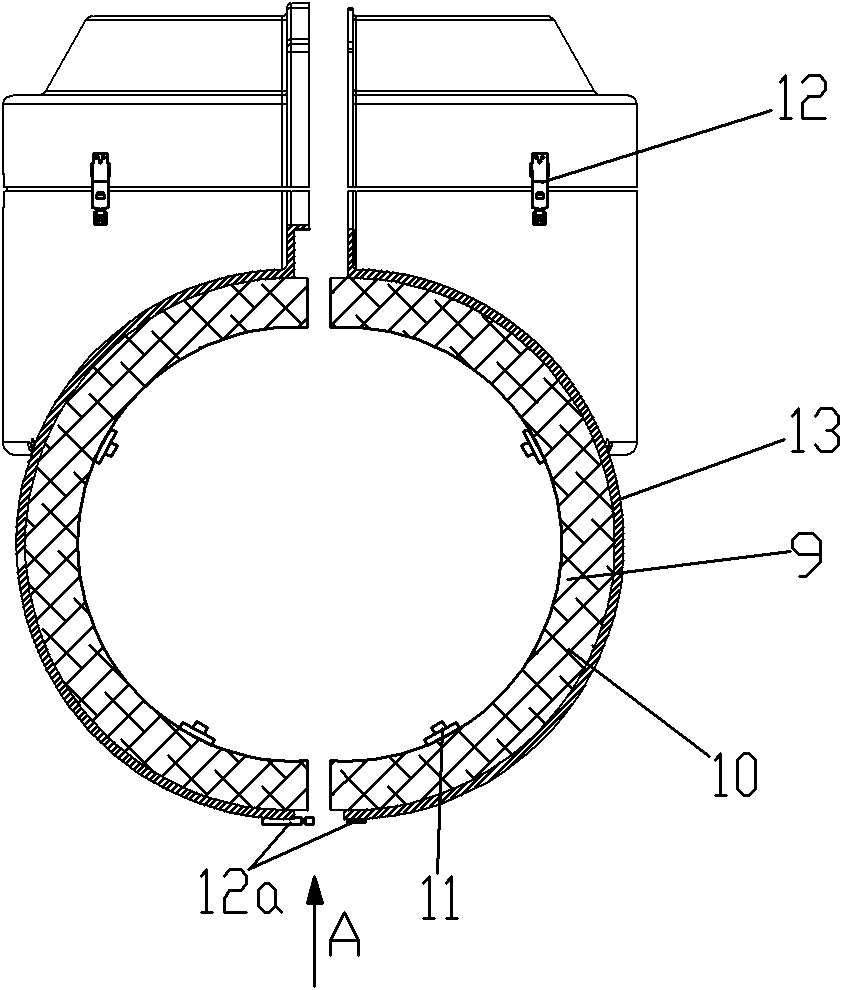

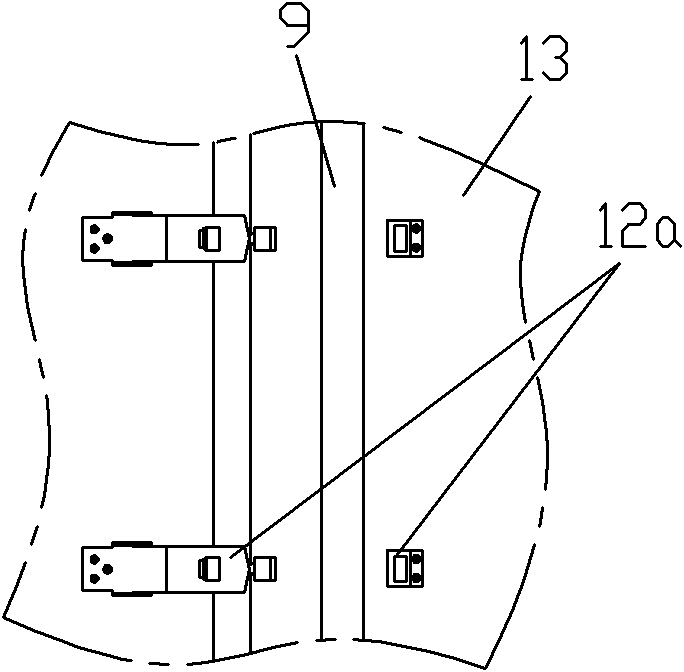

[0025] figure 1 It is a structural explosion schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the insulation cover of the present invention, image 3 for figure 1 View along direction A, Figure 4 It is a schematic diagram of the connection structure between the insulation sleeves. As shown in the figure: the gas tree quick disassembly heat preservation device, including the large four-way heat preservation cover 1 that can be put on the big four-way, the small four-way heat preservation cover that can be put on the small four-way 3, and can be put on the main The main gate valve group insulation cover on the gate valve group 2, the casing valve group insulation cover that can be placed on the casing valve group, the gas production valve group insulation cover that can be placed on the gas production valve group, and the pressure measuring valve The pressure measuring valve insulation cover 4 on the top; as shown in the figure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com