On-site hot smoke test equipment and method for subway station and inter-station tunnel

A technology for subway stations and section tunnels. It is applied to mining equipment, fire alarms that rely on smoke/gas effects, and earth-moving drilling. It can solve the problems of fire compliance that needs to be improved, few indicators, and inability to comprehensively test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

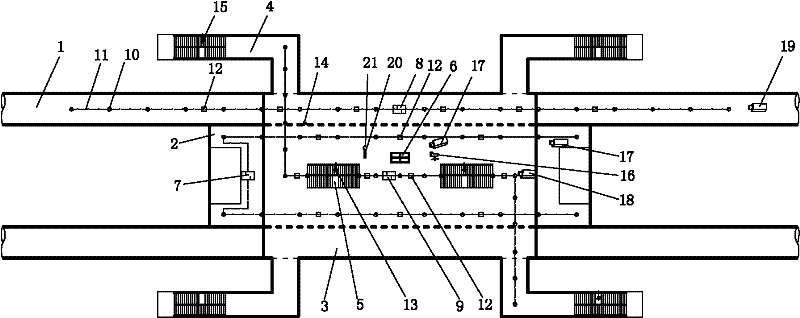

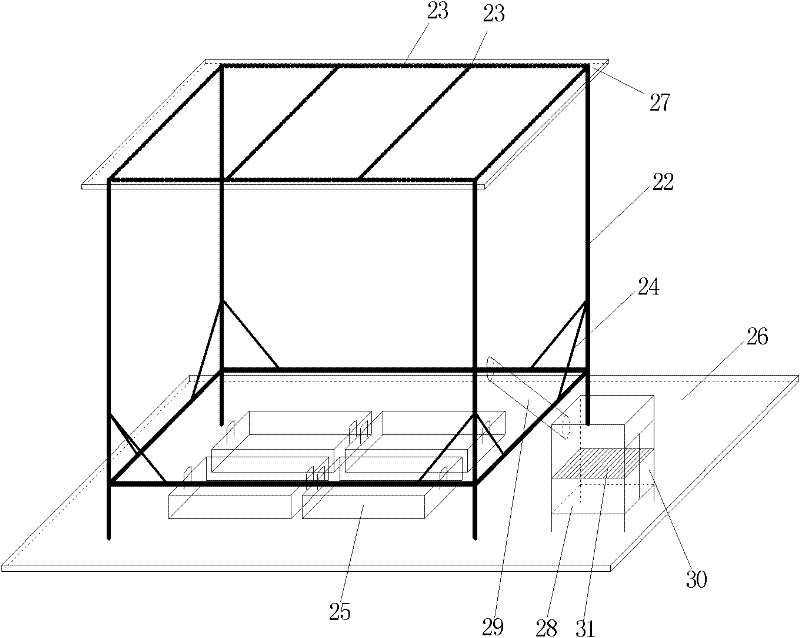

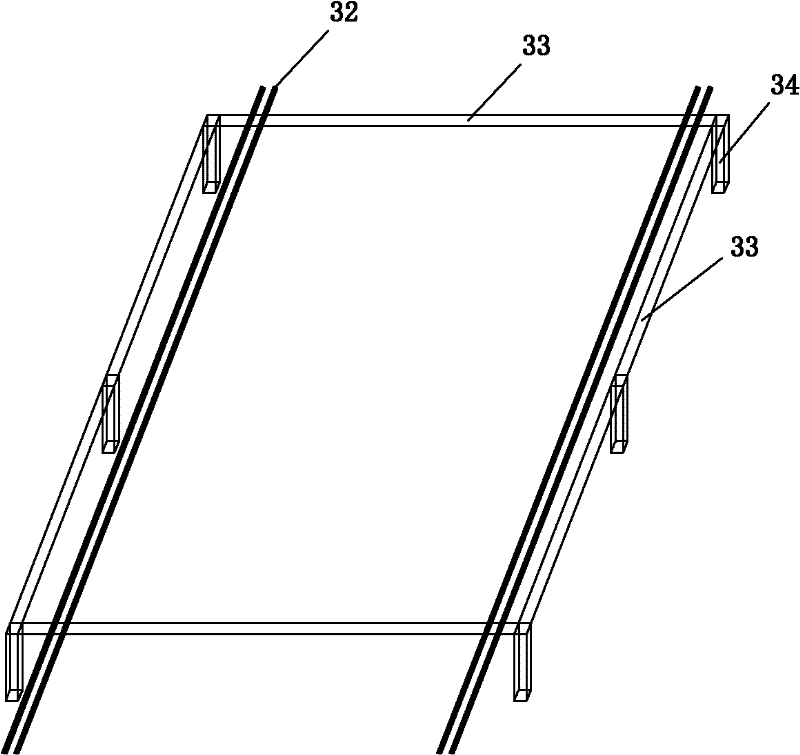

[0047] as attached figure 1 As shown, it is a schematic diagram of the distribution of on-site hot smoke testing equipment in a subway station and a section tunnel according to an embodiment of the present invention, which is used in a subway station and a section tunnel. The subway station includes tunnel 1, station platform 2, station hall 3, and station 4 entrances and exits, 5 openings for escalators on platforms / halls. The fire source system 6 can be set in the tunnel 1, the station platform 2, and the station hall 3. The fire source system 6 is used to simulate fire scenes with different powers to generate hot smoke close to the real fire. In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com