Truck scale sensor for detecting quantity of automobile tires

A technology for automobile tires and sensors, applied in the field of sensors, can solve the problems of permanent damage, sensitive components cannot be accurately detected, and sensitive components are easily damaged, and achieves the effect of stable and reliable work, accurate movement and solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

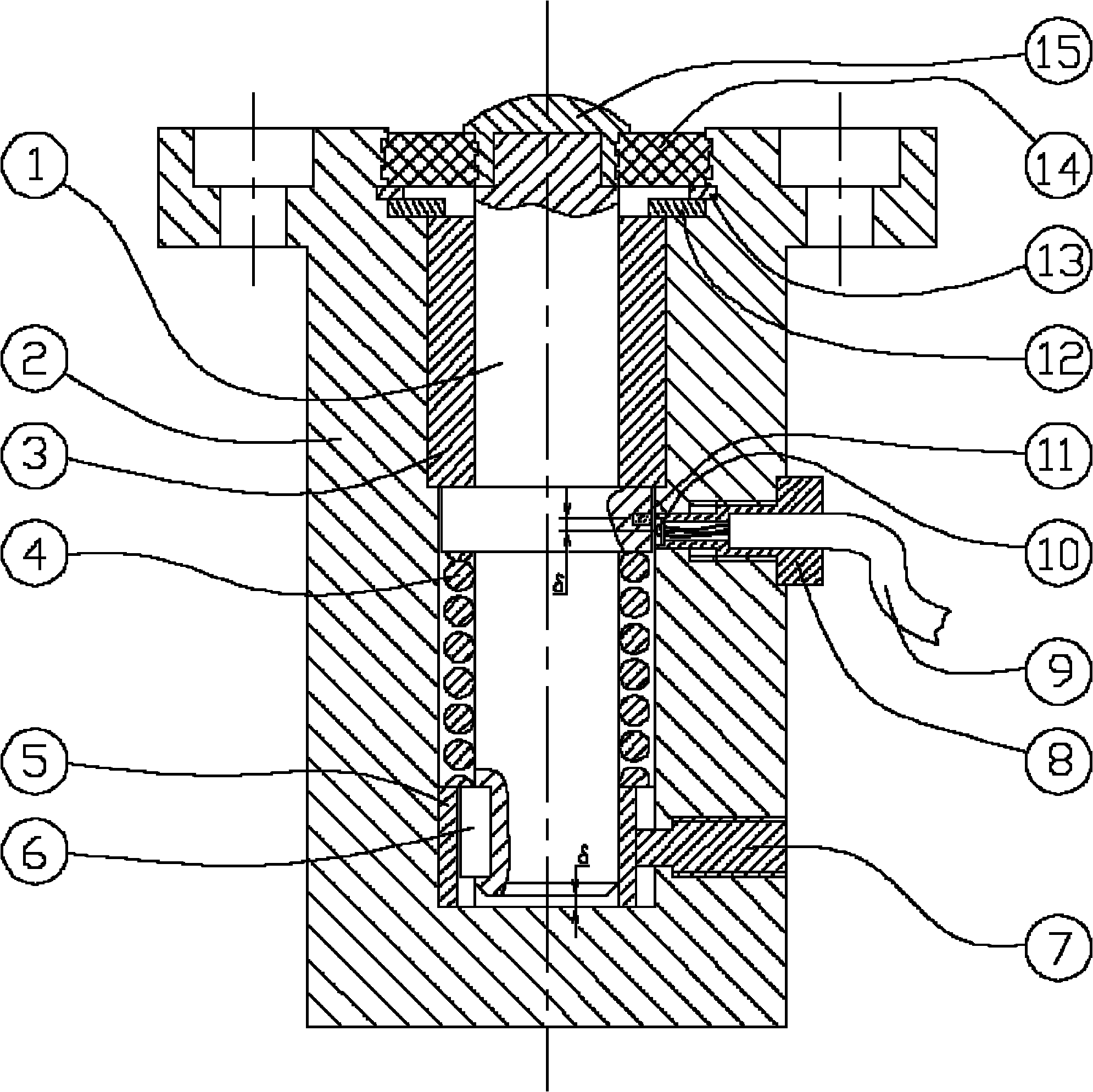

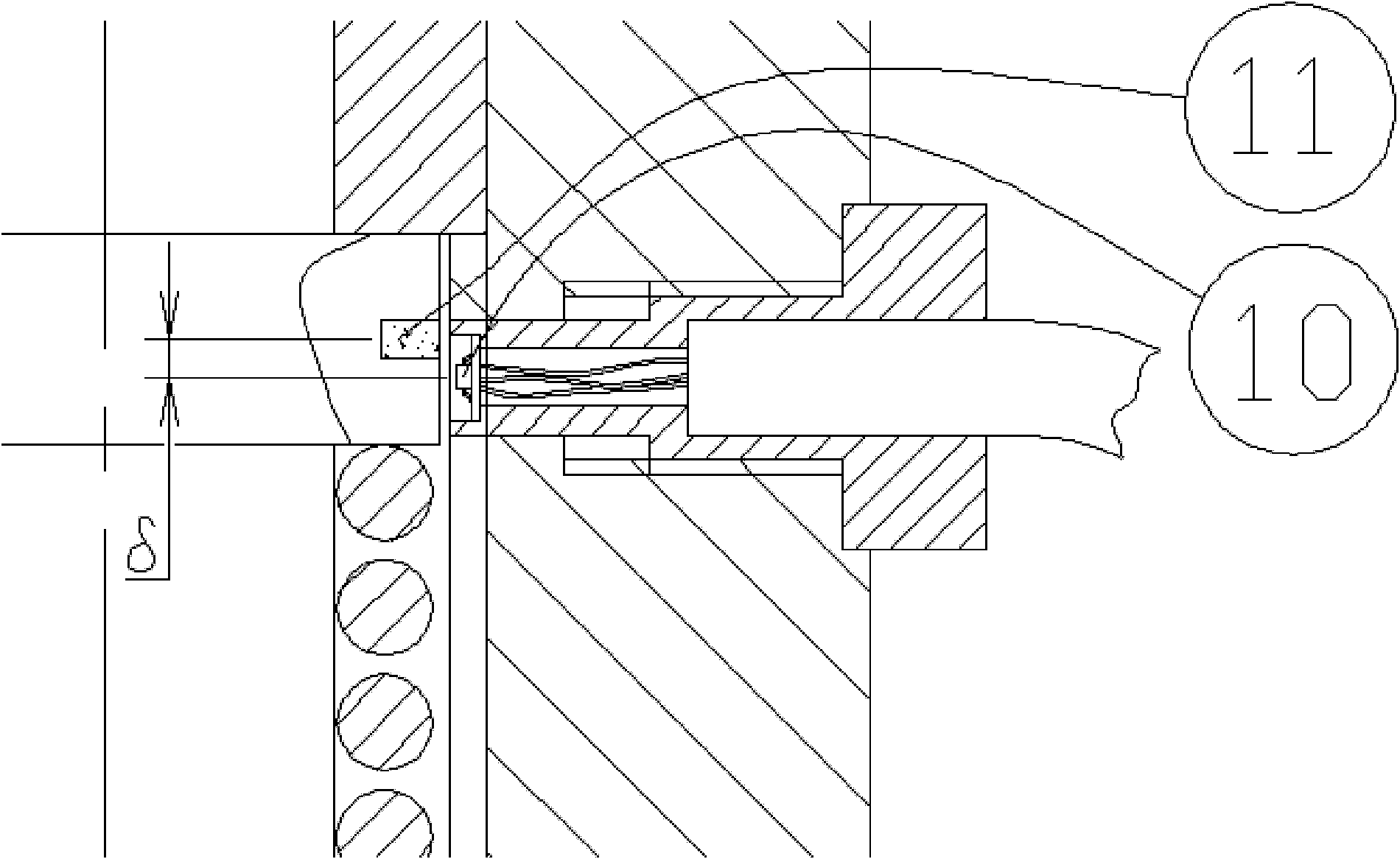

[0024] An embodiment of the sensor of the present invention is as figure 1 , 2 shown.

[0025] The base (2) is installed on one end of the truck scale or on a special support, and its upper surface is flush with the road surface; the middle and lower part of the support shaft (1) is installed inside the base (2); the upper bushing (3) and the inner hole of the lower bushing (5) and the support shaft (1) are clearance fit, and the inner circular surface of the bushing should be provided with an oil guide groove; the lower end of the lower bushing (5) and the inner cavity of the base (2) contact with the bottom, and fixed by the screw (7); the upper bushing (3) is fixed in the vertical direction by the washer (12) and the stop ring (13); one end of the return spring (4) pushes against the lower bushing (5) The upper end of the upper end of the support shaft (1) and the other end against the flange in the middle of the support shaft (1); the key (6) and the keyway on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com