Combustion turbine in which combustion is intermittent

A gas turbine and turbine technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as unbalanced flow, power output, loss, etc., to avoid output loss, compact and linear structure, and improve acoustics. coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

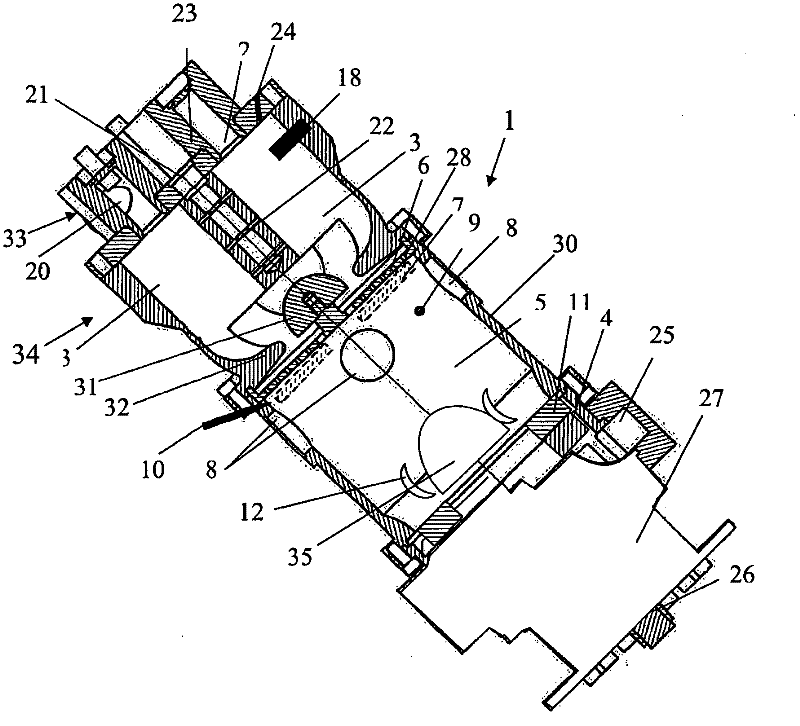

[0036] figure 1 Shown is a longitudinal section through a possible embodiment of the invention. The depicted gas turbine 1 essentially consists of a primary valve head 33 , a combustion chamber region 34 , a subsequent flow chamber 5 , a turbine 4 and a drive shaft 26 with a bearing housing 27 .

[0037] The primary valve head 33 is firmly connected to the combustion chamber region 34 and it delineates the upper side of the combustion chamber 3 . The inlet valve 2 arranged in the valve holder 23 is housed inside the primary valve head 33 .

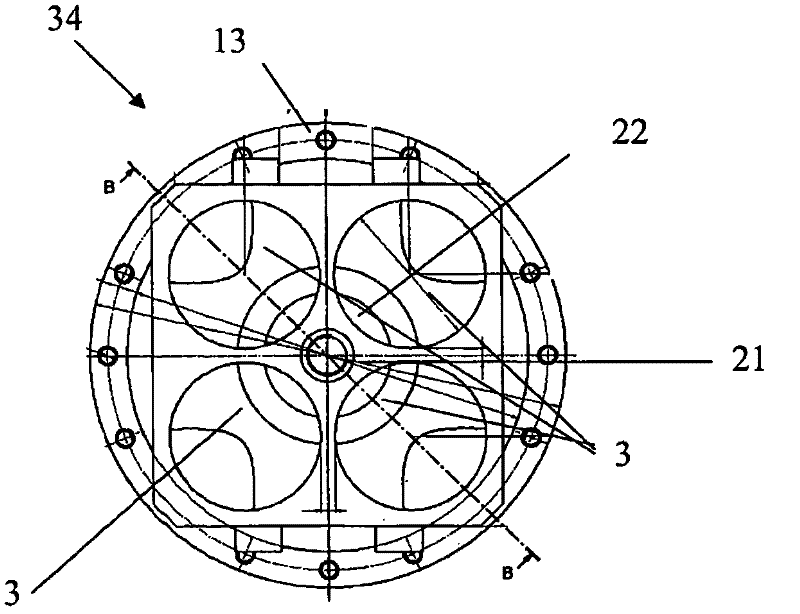

[0038] In the present example, the combustion chamber area 34 comprises four cylindrical combustion chambers 3 into which air is fed via air inlet openings 20 , inlet valves 2 , and fuel via a fuel supply system 24 , respectively. The fuel supply system 24 can be designed as one or several injection nozzles (a single nozzle or a bank of nozzles, such as piezoelectric injectors).

[0039]It is also conceivable to add fuel to the air outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com