Beverage preparation method

A beverage and injection head technology, which is applied in beverage preparation devices, household appliances, applications, etc., to reduce costs, avoid cost increases, and optimize structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

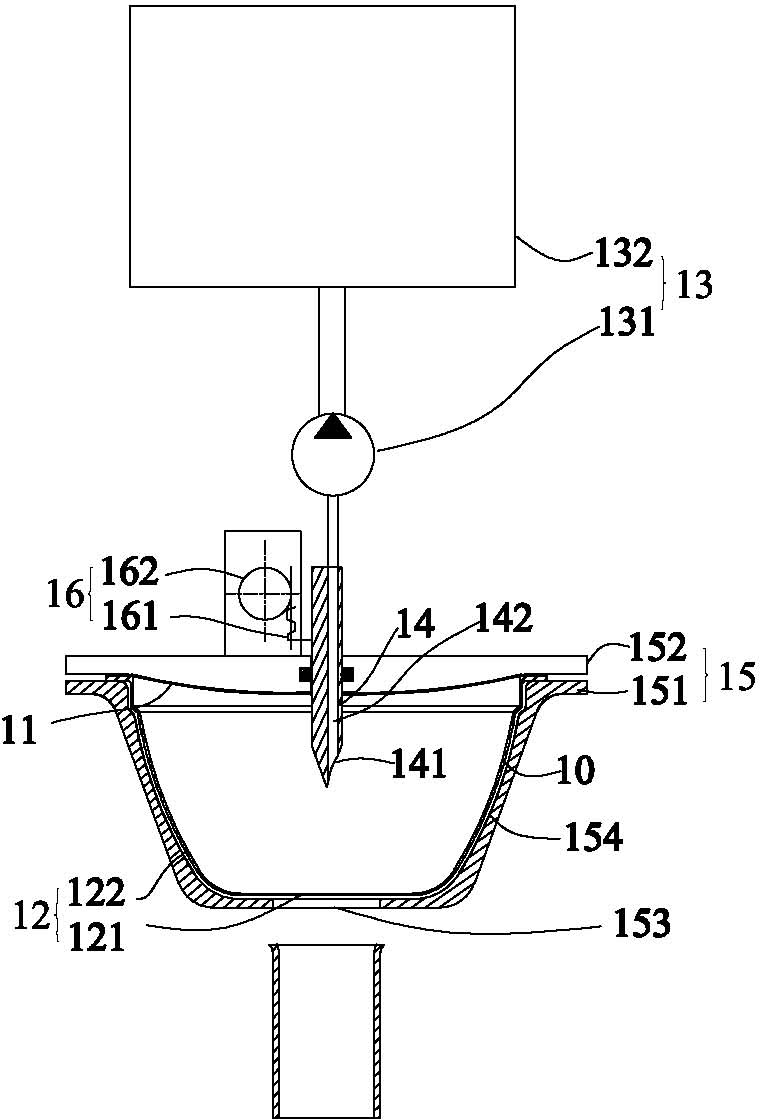

[0037] see figure 1 A first preferred embodiment of the method of beverage preparation according to the present invention is shown. In the beverage preparation method, the liquid in the liquid supply mechanism 12 is introduced into the bag 10 carried in the holder 15 through the needle 14 to make a beverage, and the holder 15 has a liquid outlet 153 . One end of the needle 14 communicates with the liquid supply mechanism 16 , and the other end is aimed at the material bag 10 .

[0038] The material bag 10 includes a membrane 11 and a container 12 , and the container 12 includes a bottom wall 121 and a side wall 122 extending upward from the bottom wall 121 .

[0039] The liquid supply mechanism 13 includes a liquid pump 131 and a water tank 132 . One end of the liquid pump 131 is connected to the water tank 132 , and the other end is in communication with the needle 14 .

[0040] The puncture needle 14 is a hollow needle-like member in this embodiment, and the needle-like ...

Embodiment approach 2

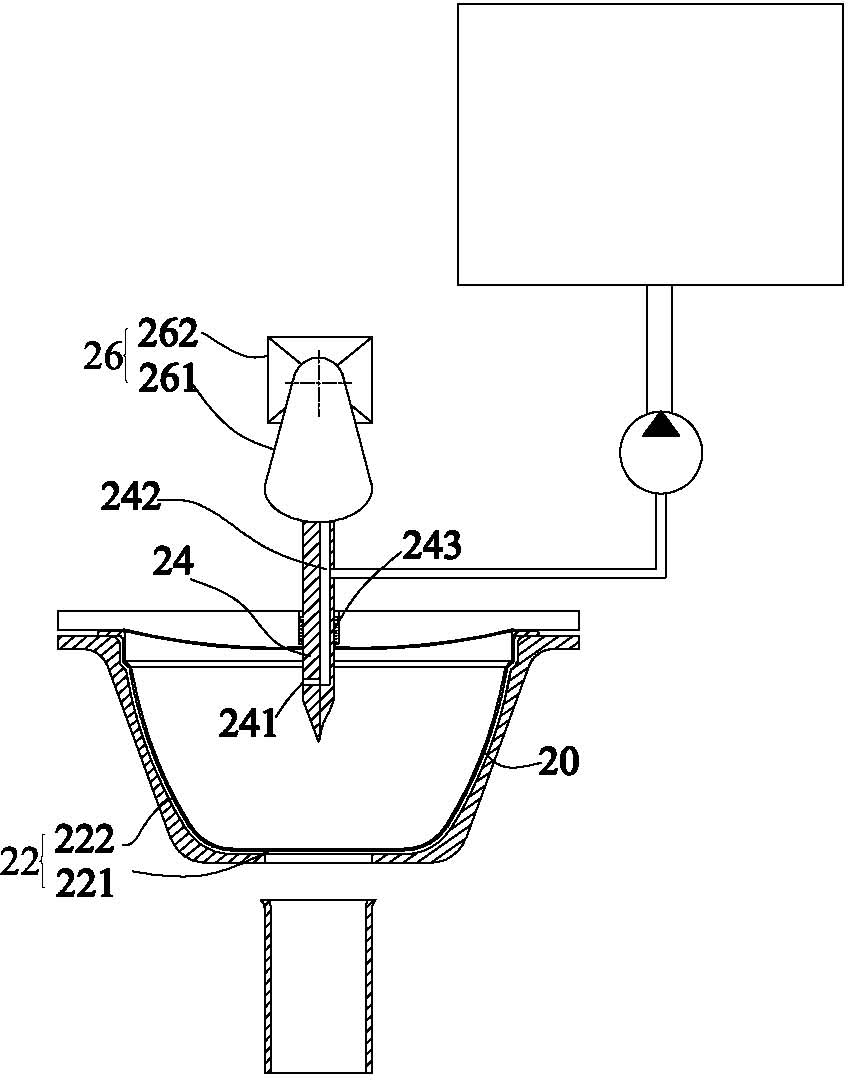

[0052] see figure 2 The second preferred embodiment of the beverage preparation method of the present invention is shown. The difference between this embodiment and the first embodiment is that: the transmission mechanism 26 is a cam mechanism, and the injection direction of the injection head 241 faces the direction of the container 22. The side wall 222 also includes a return spring 243 .

[0053] The transmission mechanism 26 includes a cam bracket 262 and a cam 261 , and the return spring 243 can be arranged on the needle 24 or separately from the needle 24 .

[0054] When using the material bag 20 to make a beverage, at least the following steps are included:

[0055] (1) The puncture process of the material bag;

[0056] (2) Brewing process.

[0057] In the beverage preparation method, the drive mechanism (not shown) drives the cam 261 to rotate, and at the same time compresses the return spring 243, thereby causing the needle 24 to move back and forth in a straight ...

Embodiment approach 3

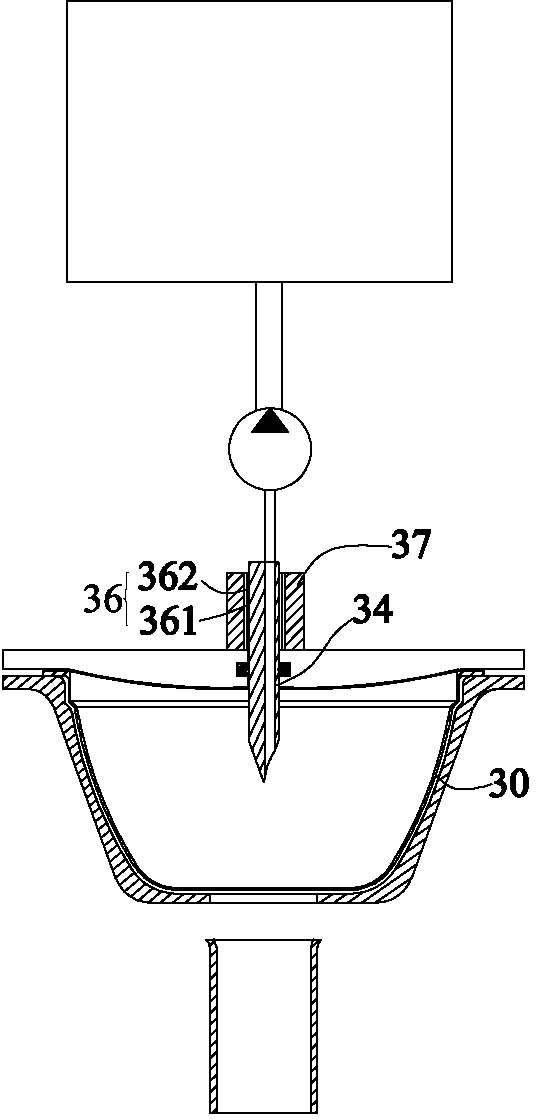

[0060] see image 3 The third preferred embodiment of the beverage preparation method of the present invention is shown. The difference between this embodiment and the first embodiment is that the transmission mechanism 36 is a threaded structure.

[0061] The transmission mechanism 36 includes an internal thread 362 and an external thread 361 provided on the needle 34 , the external thread 361 is provided on the guide block 37 , and the guide block 37 is provided on the holding cover 332 .

[0062] When using the material bag 30 to make a beverage, at least the following steps are included:

[0063] (1) The puncture process of the material bag;

[0064] (2) Brewing process.

[0065] In the beverage preparation method, the driving mechanism (not shown in the figure) drives the guide block 37 to rotate, and uses the thread structure to drive the needle 34. In addition, while reciprocating, the needle 34 also realizes the rotary motion, so that the needle punctures the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com