Conductive contact surface performance online diagnosing and repairing system and using method thereof

A technology for repairing systems and contact surfaces, applied in circuit breaker testing, circuits, electrical switches, etc., can solve the problems that the matching clearance is difficult to ensure the restoration of the best state, the fully sealed switchgear is scrapped and replaced, and the technical requirements are high. Repair efficiency and reliability, convenience and ease of operation, and the effect of reducing wear rate and cost expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

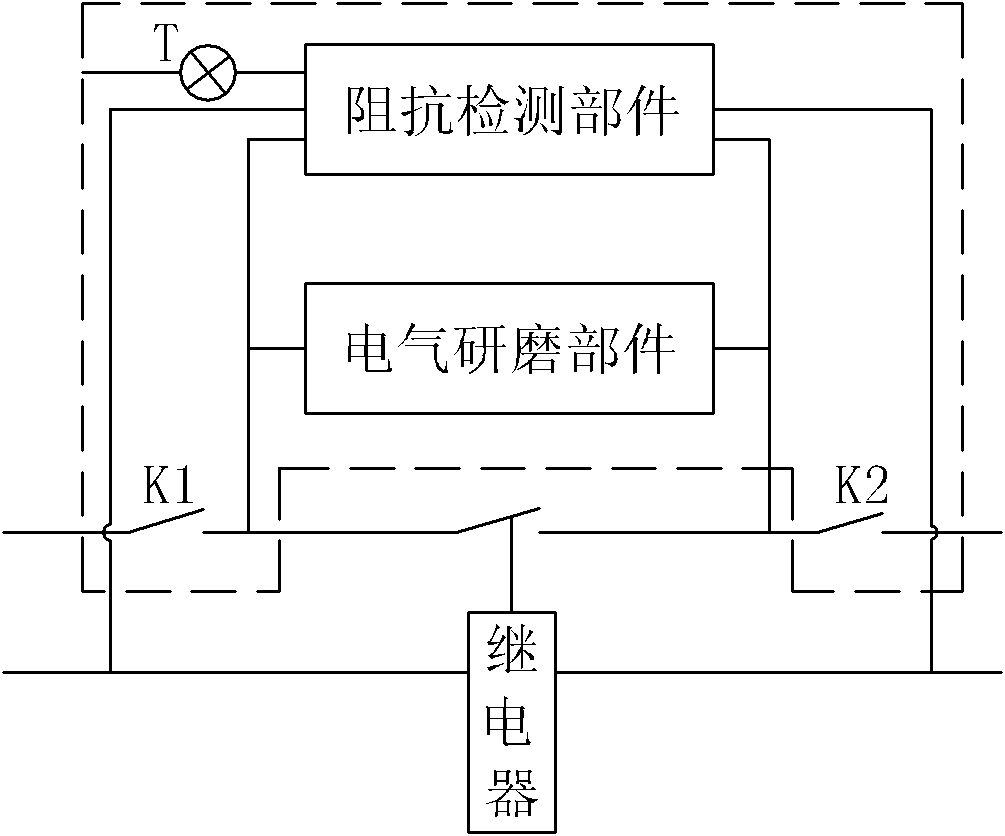

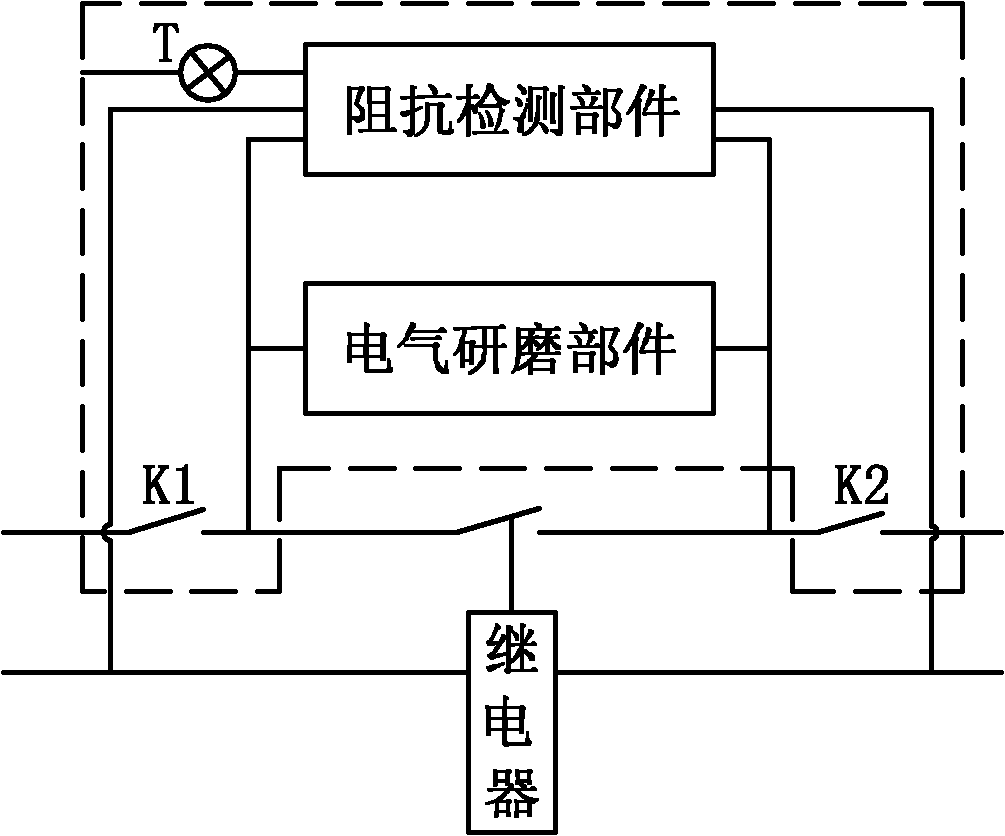

[0023] Such as figure 1 As shown, the online diagnosis and repair system for the performance of the conductive contact surface of the present invention includes an impedance detection component and an electrical grinding component, and the impedance detection component and the electrical grinding component are connected to the contacts of the relay under test, and the terminals are respectively passed through The isolating switch is connected to the external circuit, and the two ends of the impedance detection component are respectively connected to the tested relay coil to control the opening and closing of the relay contact and detect the electrification of the relay coil. Further, the isolating switch includes a first isolating switch K1 and a second isolating switch K2, both of which are controlled to be opened and closed by an electrical grinding component. Preferably, the impedance detection part is provided with an alarm indicator light T for indicating the fault state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com