Automatic water-storage and irrigation combined module vertical-face greening device

A greening device and combined technology, applied in watering devices, container cultivation, gardening, etc., can solve the problems of high planting cost of hydroponic plants, difficult to popularize facades, complex and expensive, etc., to increase greening effect and save greening occupation The effect of land area and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

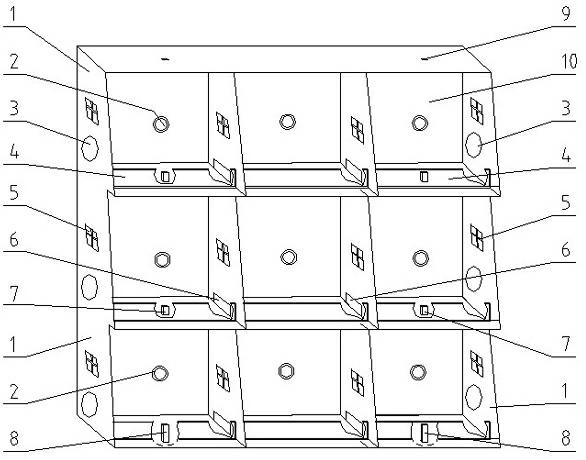

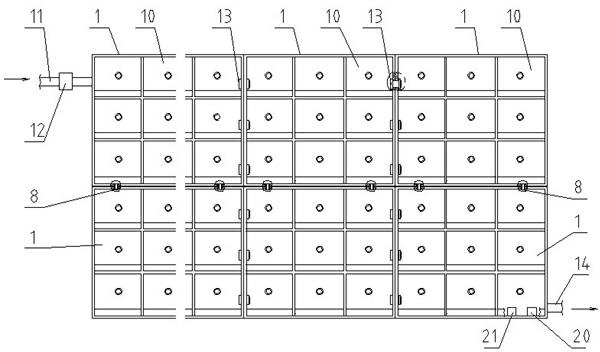

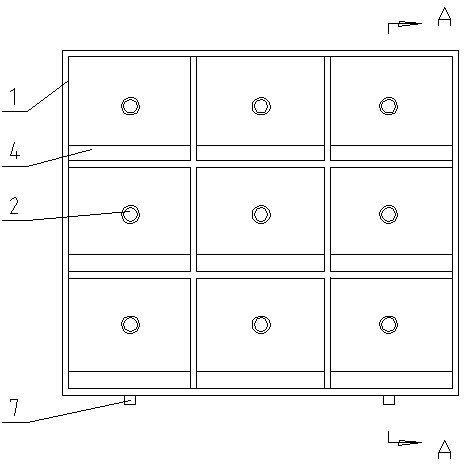

[0018] Example 1 is attached Figure 1-8 Shown: a combined modular façade greening device for automatic water storage and irrigation is composed of the same base plate 1 through the arrangement and connection of hollow connecting pipes 13 with nuts 15 and sealing gaskets 16, and the inner cavity of the base plate 1 is covered by a partition plate Divided into evenly distributed unit spaces 10; the back of the base plate 1 is closed, the outer facade is open, and the side is in a zigzag shape that matches the unit spaces 10; the middle of the rear vertical plate of the unit spaces 10 is provided with a convex shape with a through hole Conical mounting seat 2, a water barrier 4 is provided on the outside of the bottom of the unit space 10, a ventilation grill 5 is provided at the middle of the side of the unit space 10, and an intercommunication hole 6 is provided at the bottom of the side of the adjacent unit space 10; the upper part of the two sides of the base plate 1 There i...

Embodiment 2

[0022] Example 2 When carrying out hydroponic plant cultivation, no automatic irrigation system and plant planting pot are needed, only the water inlet pipe at the top of the base plate and the drain pipe at the bottom and the water pump need to be connected to form a water circulation system, and the water retaining vertical plate and The water-limiting overflow pipe increases the water storage level and installs a plant fixing plate to realize the circulation of the nutrient solution of the hydroponic plant and carry out the three-dimensional cultivation of the hydroponic plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com