Gel material for desert planting and preparation method and using method thereof

A technology of colloidal materials and plant fiber materials, which is applied in the field of materials for desert greening control, can solve the problems of destroying the biosphere, the natural environment, and the water system, and achieve the effects of reducing greening costs, good greening effects, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

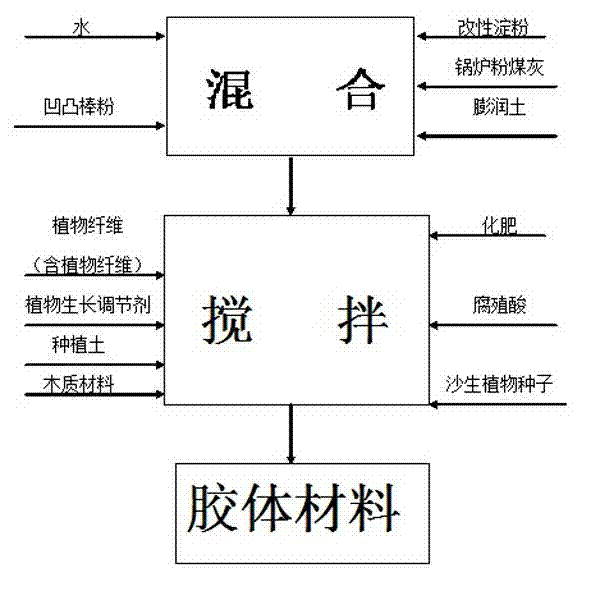

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: a kind of colloidal material that is used for desert planting, described colloidal material is made up of the material of following weight ratio:

[0044] Water 30%; Modified starch 1%;

[0045] Boiler fly ash 3%; Attapulgite powder 8%;

[0046] Bentonite 6%; Plant fiber material 16%;

[0047] Chemical fertilizer 0.5%; Plant growth regulator 0.0005%;

[0048] Humic acid 0.5%; Planting soil in farmland and orchard 30%;

[0049] Psammophyte seeds 0.0003%; woody materials 5%.

[0050] Described water refers to agricultural irrigation water, tap water, surface water, lake water, river water, domestic waste water;

[0051] The modified starch refers to modified grain starch, modified sweet potato starch, and modified potato starch produced in the food industry; the modified starch plays the role of water retention and binding.

[0052] The boiler fly ash refers to the fly ash removed from the smoke and dust removal of industrial boilers; the boiler fly ash...

Embodiment 2

[0063] Embodiment 2: Same as Embodiment 1, the difference is:

[0064] Water 40%; Modified starch 1.3%;

[0065] Boiler fly ash 2%; Attapulgite powder 5%;

[0066] Bentonite 4%; Plant fiber material 20%;

[0067] Chemical fertilizer 0.1%; Plant growth regulator 0.0003%;

[0068] Humic acid 0.1%; planting soil in farmland and orchard 25%;

[0069] Psammophyte seeds 0.0002%; Woody materials 2.4995%.

Embodiment 3

[0070] Embodiment 3: the same as Embodiment 1, the difference is:

[0071] Water 60%; Modified starch 0.1%;

[0072] Boiler fly ash 1%; Attapulgite powder 2%;

[0073] Bentonite 2%; Plant fiber material 10%;

[0074] Chemical fertilizer 0.001%; Plant growth regulator 0.0002%;

[0075] Humic acid 0.01%; Planting soil in farmland and orchard 24.39%;

[0076] Psammophyte seeds 0.0001%; woody materials 0.5%.

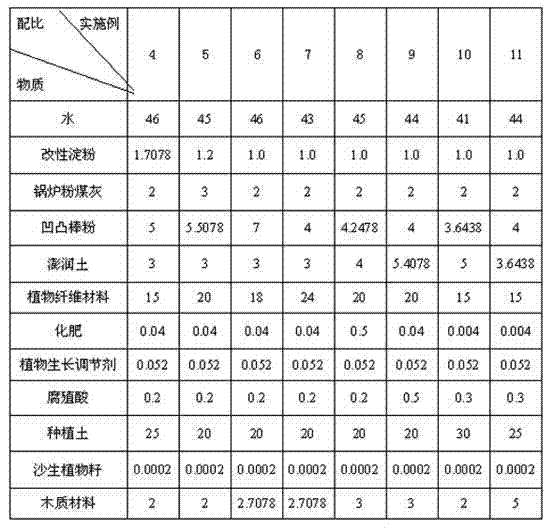

[0077] According to the natural conditions and landform conditions of the greening desert, the particle size of the desert sand, the pH of the sand layer, the amount of nitrogen, phosphorus, potassium and organic matter in the sand layer, the present invention can be properly adjusted during practical application and construction. Examples are as follows, as shown in Table 1:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com