Channel-dividing compact-pushing auto-arranging tool for rotary powder forming presses

An automatic arrangement and rotation technology, which is applied in the field of forming tooling for soft ferrite blanks, can solve the problems of high wages and other costs, many production steps, poor mechanical strength, etc., and achieves reduced labor intensity, easy replacement of templates, and blanks. The effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

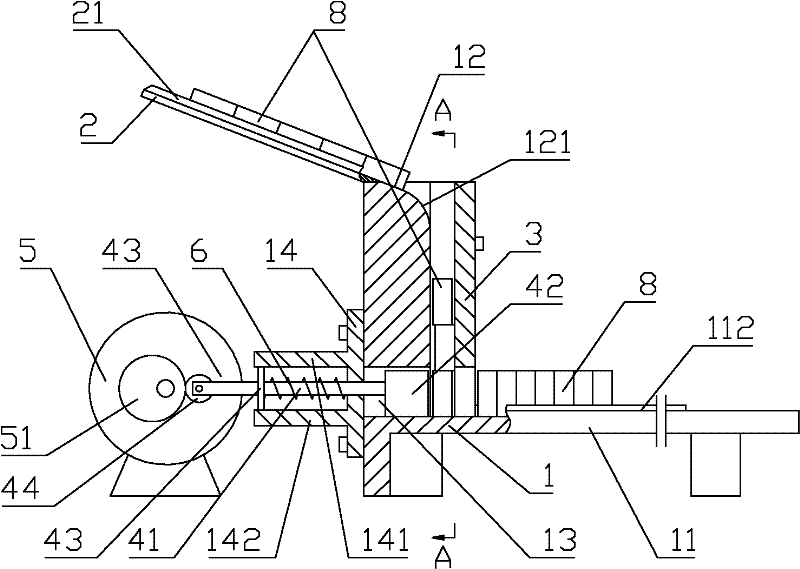

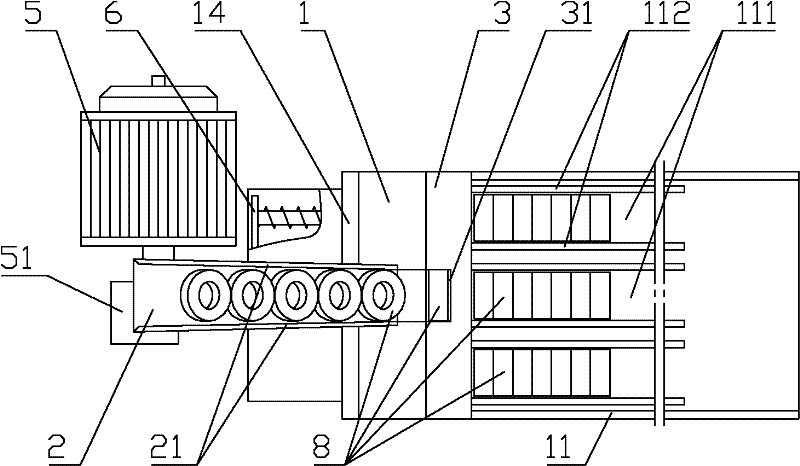

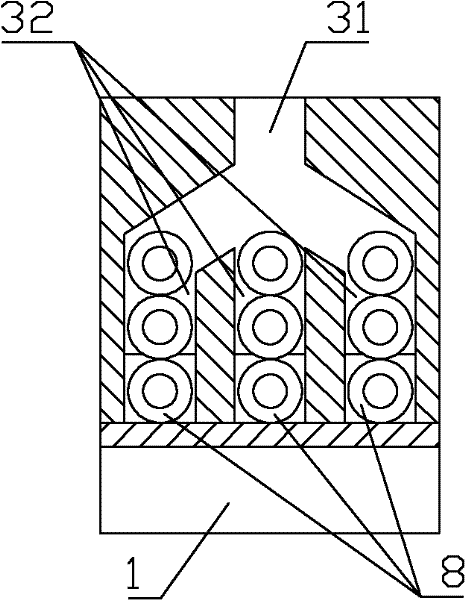

[0023] Such as Figures 1 to 3 Shown is a structural schematic diagram of an embodiment of the present invention, the rotary powder molding press is divided into lanes and pushes billets automatically arranged tooling, including a base 1, and a discharge slide rail 2 connected with the rotary press is arranged above the base. The seat is provided with a discharge platform 11 for the green compact 8 to slide, and a discharge platform 11 is provided between the discharge slide rail and the discharge platform so that the single-track sliding of the green compact on the discharge slide rail becomes multiple on the discharge platform. The lane-sliding lane structure, there is also an inverted structure between the discharge slide rail and the lane-divided structure to make the green compact inverted into a vertical direction, and behind the discharge platform, there is a The reciprocating blank pushing mechanism that pushes the compact on the material platform forward.

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com