Cantilever casting construction cradle with underlaid main truss

A main truss and truss hanging technology is applied in the field of hanging and pouring construction hanging baskets under the main truss, which can solve the problems of occupying upper construction space, insufficient construction space, lag in the construction period of continuous beam pouring, etc., so as to save construction space and move forward the process. The effect of stable and convenient hanging basket elevation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

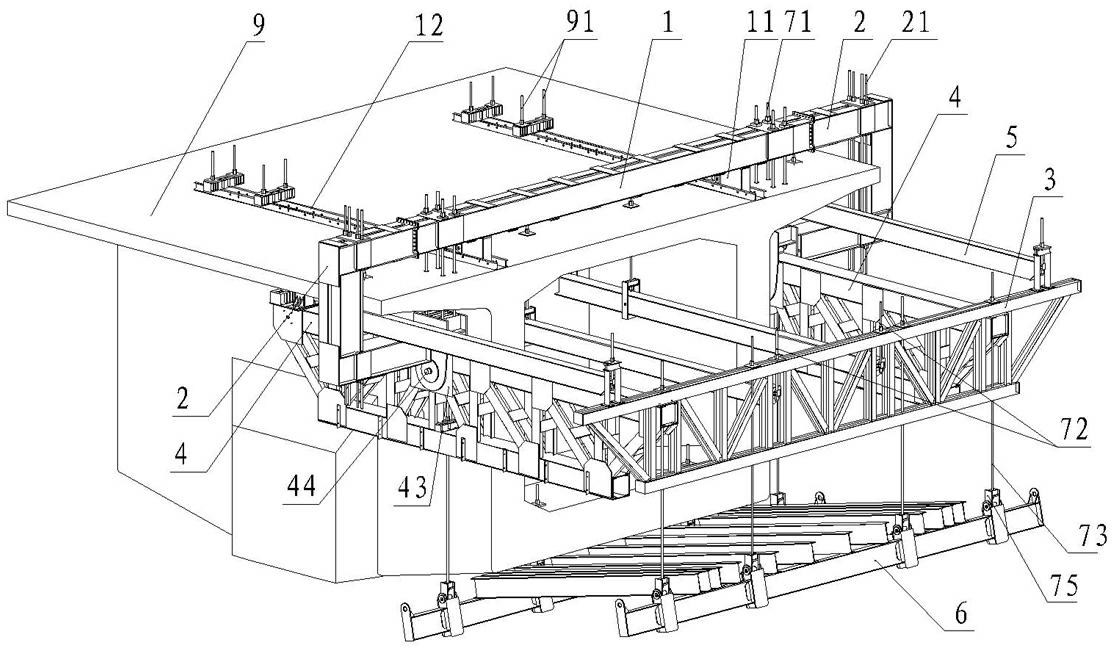

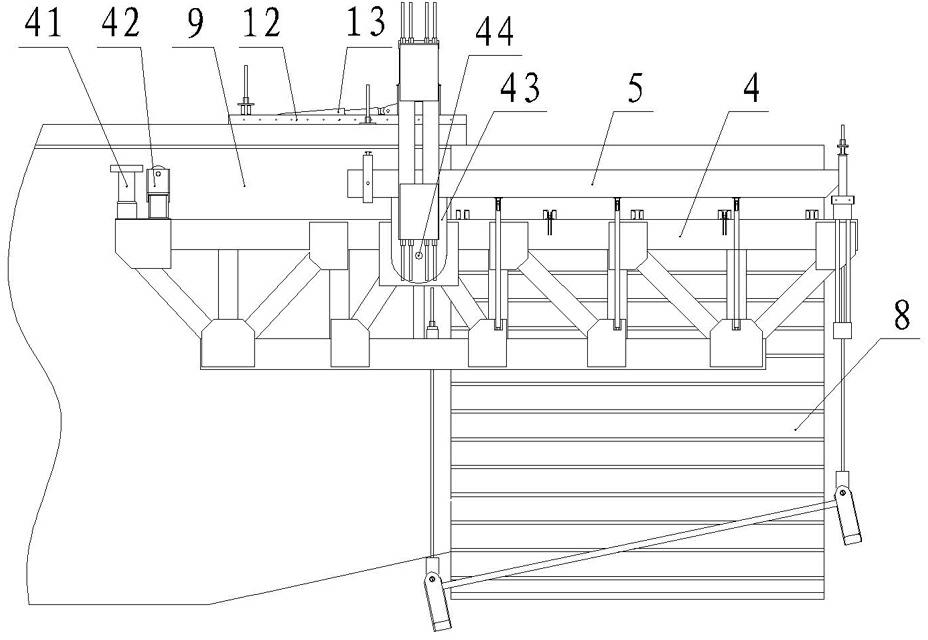

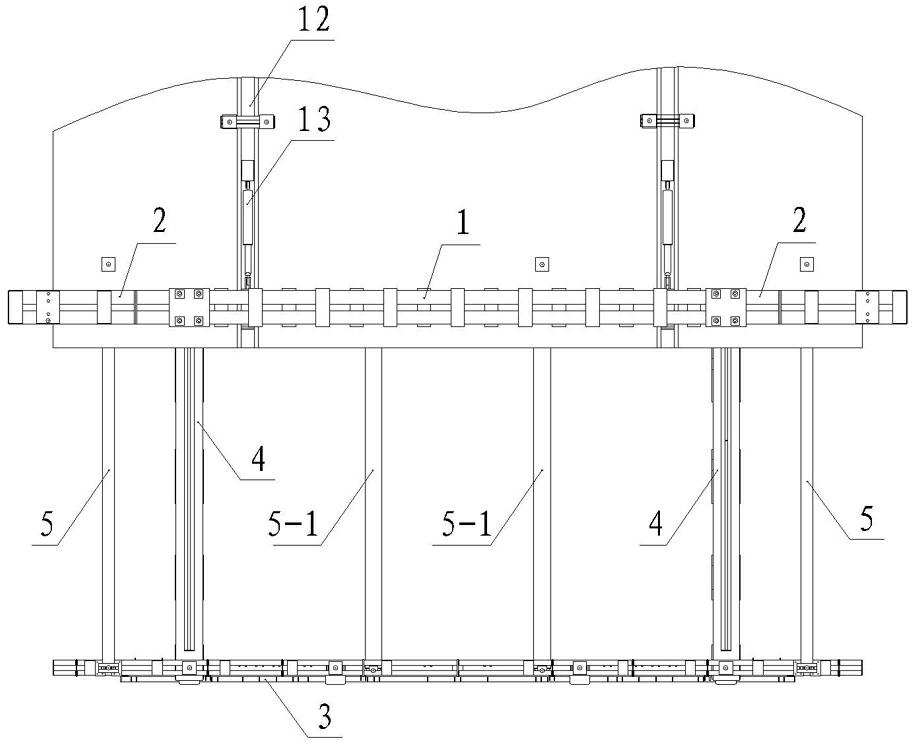

[0020] refer to figure 1 , Figure 5 , this embodiment includes a main truss 4 and a running mechanism. The main truss 4 is symmetrically placed on both sides of the lower part of the poured beam 9; 43; the upper part of the main truss hanger 43 reaming holes is provided with a vertical groove 100 in the same direction; the upper part of the front end of the poured beam 9 is horizontally installed with a rear beam 1, and the two ends of the rear beam 1 are respectively connected to one end of the C-shaped arm 2, and the C The other end of shaped arm 2 is vertically downward, and its end horizontally stretches in the vertical groove 100 of described main truss hanger 43.

[0021] refer to figure 2 , Figure 4 . The supporting rolling device is a supporting oil cylinder 41 and a roller frame 42 installed on the upper edge of the main truss 4 in sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com