Method for measuring micro-tube density in SiC (silicon carbide) crystal

A technology of crystals and micropipes, which is applied in the field of measuring the density of micropipes in SiC crystals, and can solve the problems of not being able to measure the measured area at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

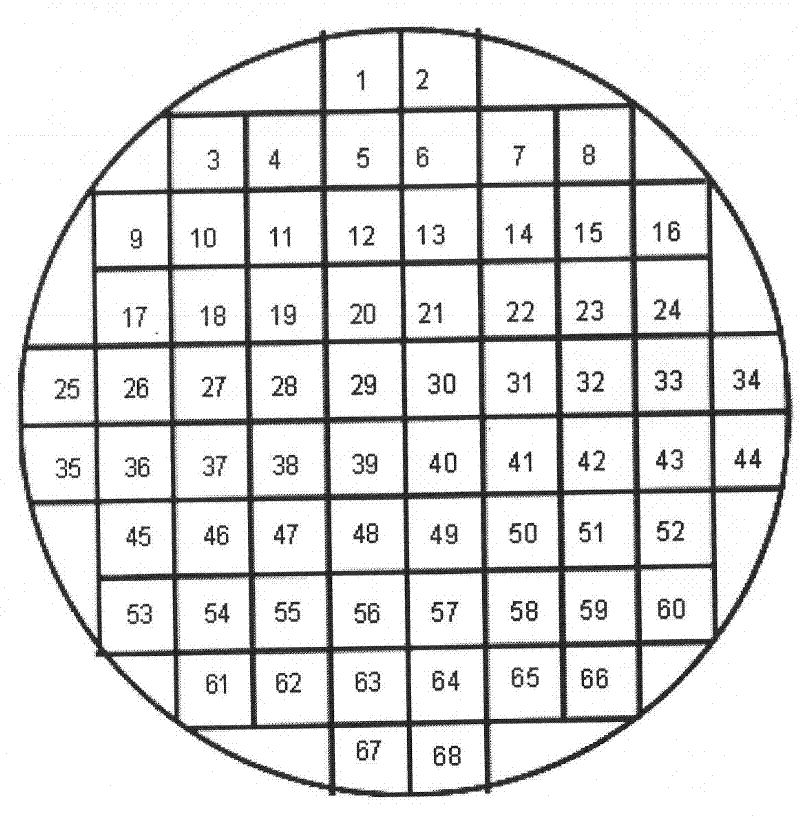

[0027] Example 1: Micropipe measurement was performed on a 4H-SiC wafer with a wafer diameter of 50.8 mm.

[0028] The microscope is a microscope from Japan OLYMPUS Company, with a magnification of 50 times, and the field of view is calibrated with a ruler, and the field of view under 50 times is 15.6mm 2 .

[0029] Microtubule distribution as Figure 4 As shown, according to the total number of micropipes on the obtained wafer area is 123 (the number of micropipes in the blank area is zero), then:

[0030]

Embodiment 2

[0031] Example 2: Micropipe measurement was performed on a 6H-SiC wafer with a wafer diameter of 75.6 mm. The microscope is a microscope from Japan OLYMPUS Company, with a magnification of 50 times, and the field of view is calibrated with a ruler, and the field of view under 50 times is 15.6mm 2 .

[0032] Microtubule distribution as Figure 6 As shown, according to the total number of micropipes on the obtained wafer area is 142 (the number of micropipes in the blank area is zero), then:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com