Rotating speed control method and device

A speed control and speed technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of shortening the service life of the rotating device and related hardware, switching the device speed back and forth, reducing system reliability, etc., to achieve temperature stability and prolong use Effects of life and shortened service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example one

[0030] In view of the defects of the existing fan speed control methods, this example provides a fan speed control method, aiming to eliminate the defects of these existing methods. Under the conditions of ensuring the safe heat dissipation of equipment and minimizing equipment noise, the reliability of the system is further improved.

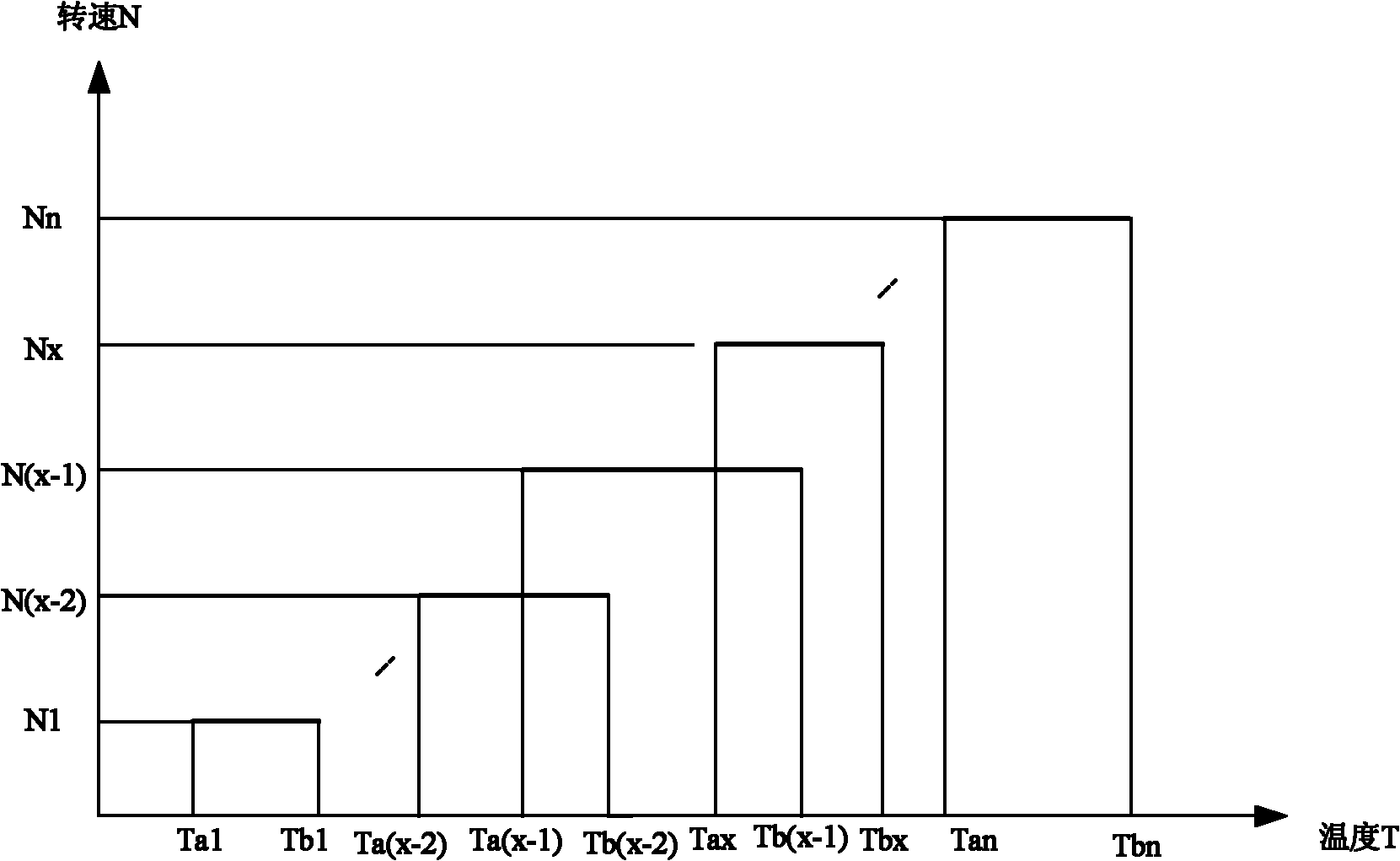

[0031] The principle of the technical solution adopted in this example can be found in figure 2 , For the convenience of description, define here figure 2 The principle shown is multi-stage speed regulation with return difference. The specific implementation plan is as follows:

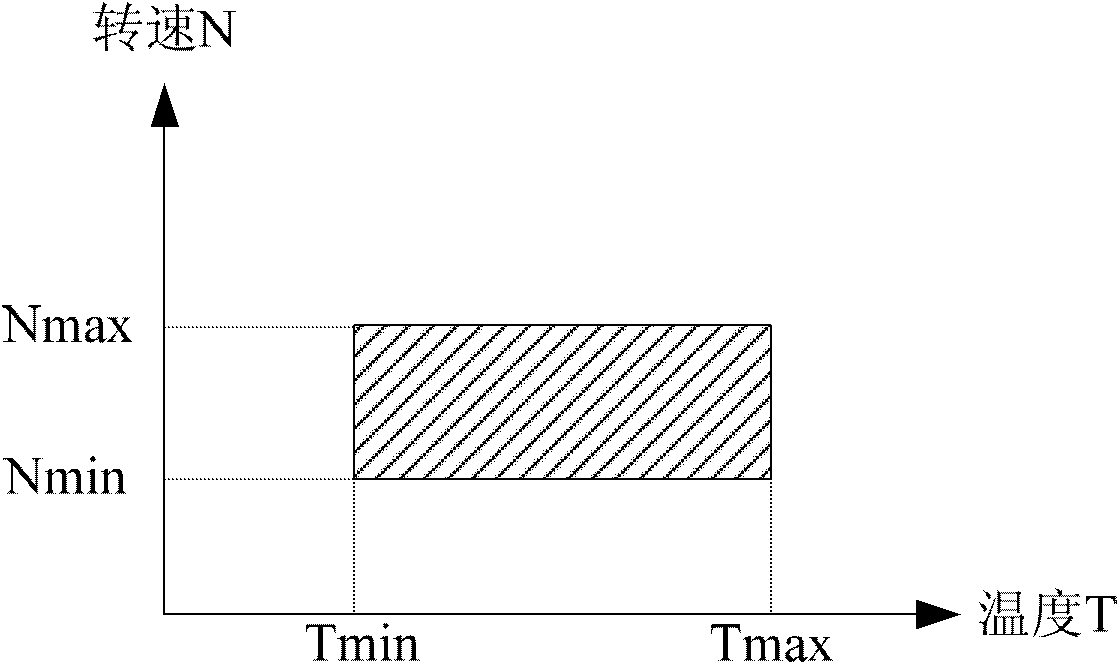

[0032] Set the speed corresponding to a certain temperature range. The minimum and maximum values corresponding to each temperature range are Tax and Tbx (x=1, 2,..., n; n is the number of sections divided by temperature), and the rotation speed corresponding to the range from Tax to Tbx is Nx. Different from the existing speed control method, when...

Example Embodiment

[0047] Example two

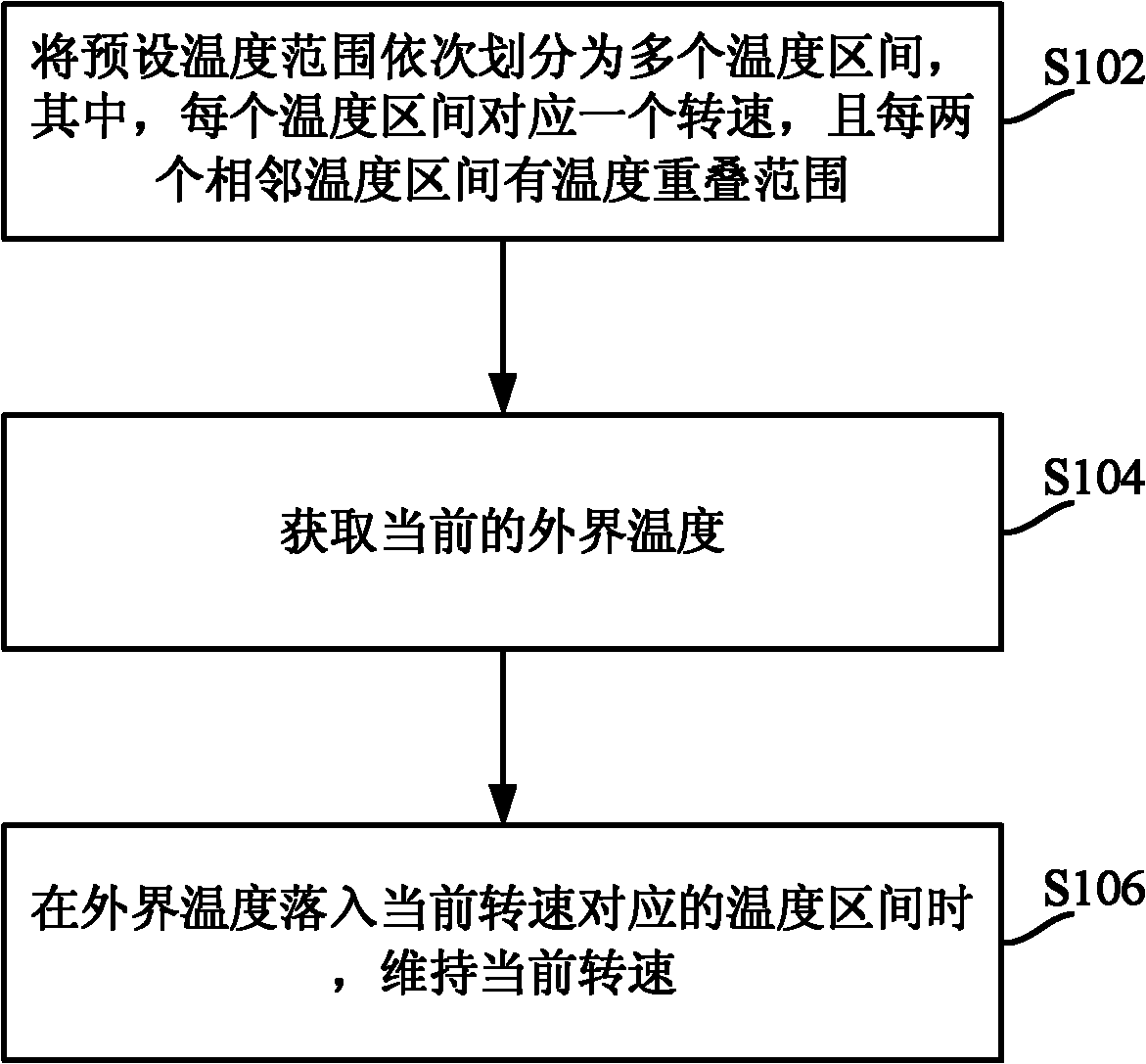

[0048] This example can be implemented based on the technical principle described in Example 1, and the principles of related steps can be referred to the description in Example 1, which will not be repeated in this example. Such as Figure 5 As shown, the fan speed control method in this example includes:

[0049] In step S502, a plurality of temperature intervals with return difference are set, and a rotation speed corresponding to each temperature interval is defined. For the specific implementation principle, please refer to the relevant description in the example, which will not be repeated here.

[0050] Step S504: Read the system temperature.

[0051] Step S506: Determine which temperature interval the read system temperature falls into and record the determined temperature interval.

[0052] Step S508, read the outside temperature again.

[0053] In step S510, it is judged whether the external temperature read in S508 falls within the temperature range reco...

Example Embodiment

[0057] Example three

[0058] This example provides a method for controlling the speed of a communication device fan that can be applied to a communication room. The above-mentioned communication equipment is internally composed of a main control board, a fan control board and several other single boards, and the fan speed control is completed on the fan control board. Since there is no more precise requirement for the temperature, the fan speed is divided into 4 temperature ranges, that is, 4 levels. As shown in Table 1.

[0059] Table 1 Correspondence between temperature range and fan speed

[0060] Temperature range

[0061] The following are the setting conditions of the fan speed adjustment of the fan control board:

[0062] The minimum speed of the system is controlled at 1200RPM, and the maximum speed is 3000RPM.

[0063] The speed difference from low temperature to high temperature is 300RPM, 600RPM, and 900RPM respectively.

[0064] Return difference Δ=4℃ (it is the test r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap