Method and melt channels for interrupting and restoring the melt stream of iron and metal melts in tap hole channels of blast furnaces and drainage channels of melt furnaces

A technology of exit channel and discharge channel, applied in the field of melt flow of iron and metal melt, can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

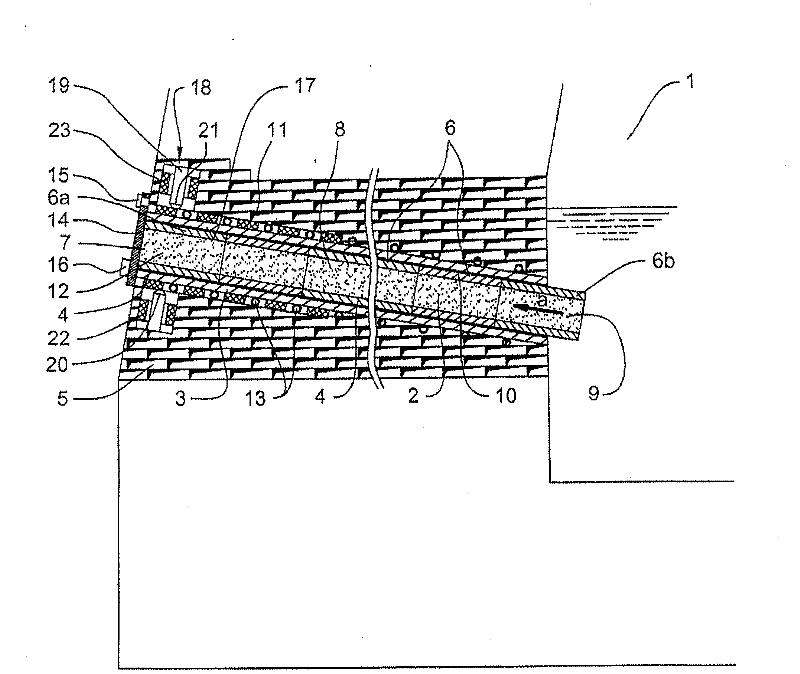

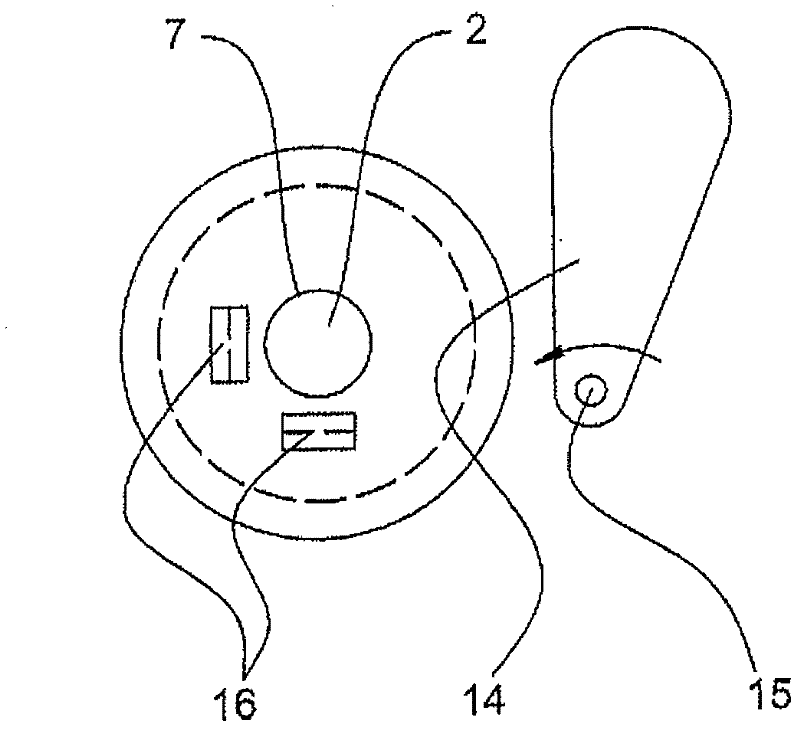

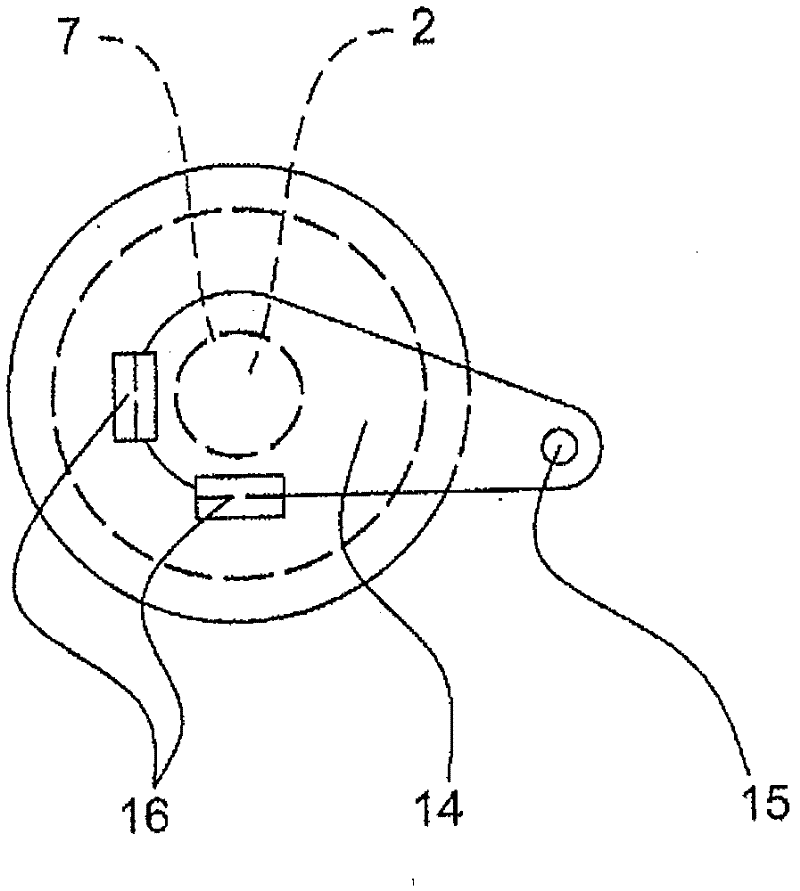

[0018] BF 1's in figure 1 The outlet channel 2 shown in FIG. 1 is formed by an outer tube 3 which is fixedly connected to a lining 5 of a blast furnace 1 and an inner tube 4 which is axially displaceable within the outer tube. The two tubes 3 , 4 consist of a high-strength material, preferably a ceramic material, and the material of the inner tube 4 for preventing abrasive wear due to escaping pig iron and escaping slag is additionally wear-resistant.

[0019] The inner tube 4 consists of a tube section 6 which is replaced at regular intervals by a new tube section 6a to compensate for the abrasive wear that occurs, wherein the new inner tube section 6a passes through the discharge opening 7 of the outlet channel 2 with the melt The flow direction a of the stream 8 is reversed into the outer tube 3 and at the same time the worn pipe section 6 b is pushed out of the outer tube 3 into the blast furnace 1 through the inlet 9 of the outlet channel 2 . The inner pipe section 6b, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com