Twisting method utilizing online idle rolling mill to twist oval rolled piece

An elliptical, rolling mill technology, applied in the field of steel rolling, can solve problems such as limited strength, damage to guide and guard devices, and broken rollers to achieve the effect of avoiding frequent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiment: The technological conditions on which this embodiment is based are: use a billet of 220mm×220mm×3500mm, roll it through a 650mm billet rolling mill for 11 passes, and roll it into a semi-finished product of Φ112mm, and then send it to the continuous rolling production line In the Φ480mm×4 rough rolling unit, two passes are rolled, and the finished round steel bars of Φ85mm are rolled.

[0012] In this embodiment, the roughing mill of the continuous rolling production line has 4 rolling mills, wherein, 2# rolling mill is used as a twisting rolling mill (not participating in rolling deformation), placed between 1# rolling mill and 3# rolling mill, 4# rolling mill Empty.

[0013] The specific steps are:

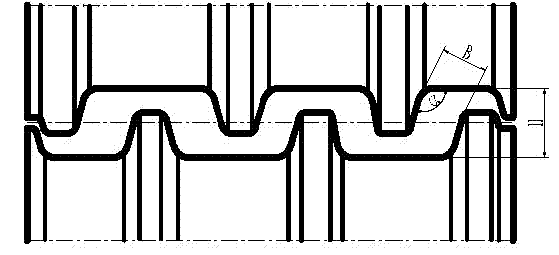

[0014] 1. Install a pair of rolls with a twist pass on the 2# rolling mill ( figure 1 shown);

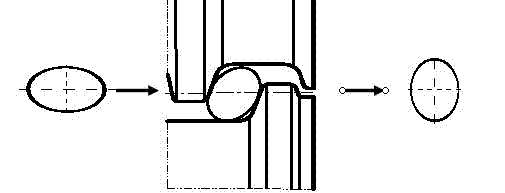

[0015] 2. Install the 2# rolling mill on-line, and place it between the 1# rolling mill that produces elliptical rolled pieces and the 3# rolling mill that produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com