Paper film-coating paper roller

A technology for laminating paper and paper, applied in the field of paper laminating paper rolls, can solve the problems of difficult temperature control of laminating paper rolls, easy damage to paper roll bearings due to heat, etc., achieving simple structure, avoiding frequent damage, and good heating effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

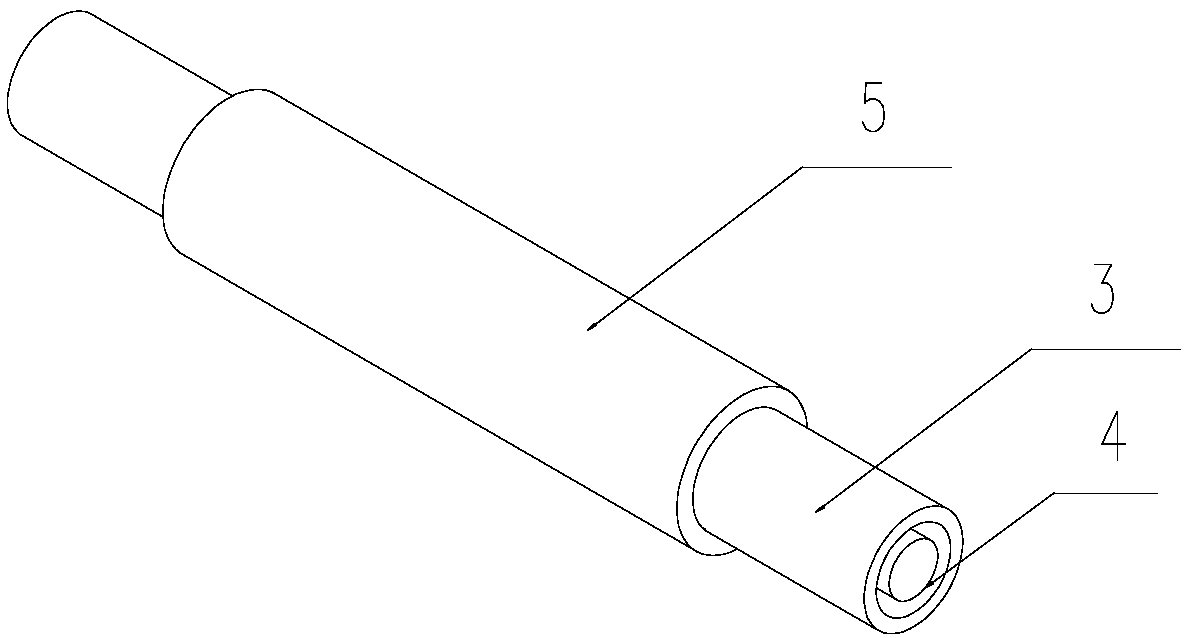

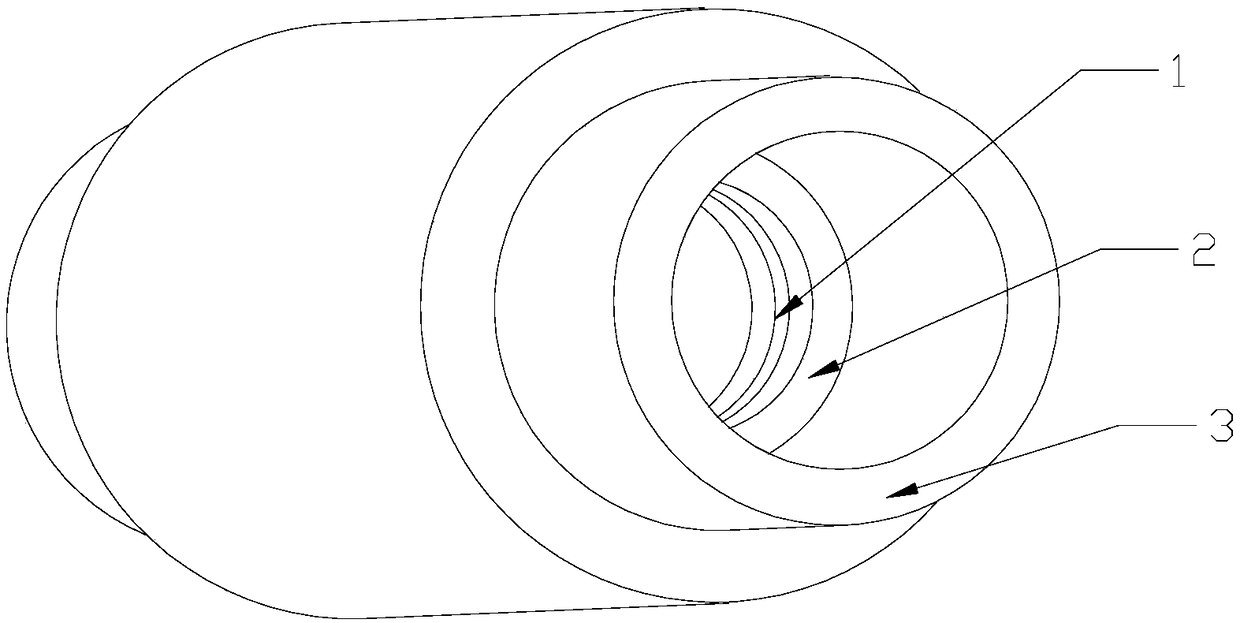

[0017] as attached figure 1 , 2 As shown, the present invention provides a paper-coated paper roll, which is characterized in that the paper-coated paper roll includes an annular groove 1, a fixed sleeve body 2, a hollow shaft 3, a heating rod 4 and a paper roll shaft 5; the hollow shaft 3 A paper roller shaft 5 is fixedly connected to the upper end, and a fixed sleeve body 2 is symmetrically fixed on both sides of the inner cavity of the hollow shaft 3, and an annular groove 1 is respectively arranged inside the two fixed sleeve bodies 2, and a heating rod is arranged in the inner cavity of the hollow shaft 3 4. There are several balls tangent to the outer contour of the heating rod 4 inside the annular groove 1. The balls are made of galvanized steel balls. The fixed sleeve body 2 is made of insulating and heat-conducting materials. The section of the annular groove 1 is semicircular. The inner balls are in contact with the fixed heating rod 4 to avoid frequent damage to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com