Layer-by-layer grouting construction method for fixed-point deep hole on the surface

A construction method and grouting technology, which are used in earth-moving drilling, underground chambers, shaft equipment, etc., can solve problems such as difficult grouting in deep holes, difficulty in adapting to the surrounding rock characteristics of different fault fracture zones, and difficulty in bearing bearing pressure. Achieve the effect of avoiding frequent damage, avoiding difficulty in pulling out, and improving stress capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

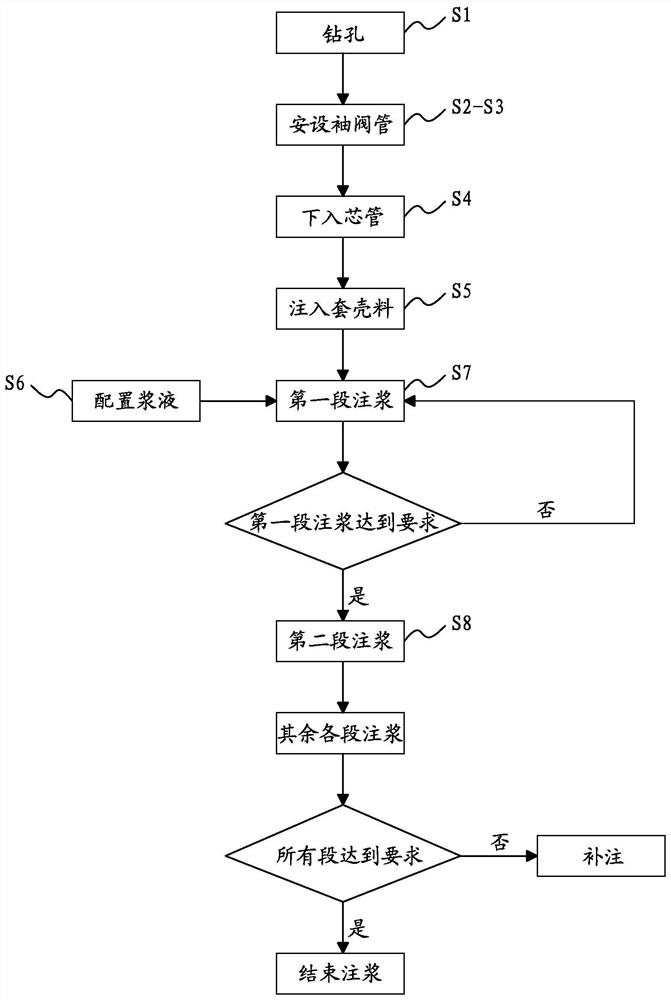

[0044] Please refer to figure 1 , 2 According to a non-limiting embodiment of the present invention, a surface fixed-point deep hole layered grouting construction method is provided, and the method includes the following steps S1-S8.

[0045] In step S1, locate the area that needs grouting and drill vertically from the construction side to the inside of the area that needs grouting. After the drilling rig completes the drilling, withdraw the drill pipe. The hole diameter is set to about 200 mm, and the hole depth is set to about 120 meters. .

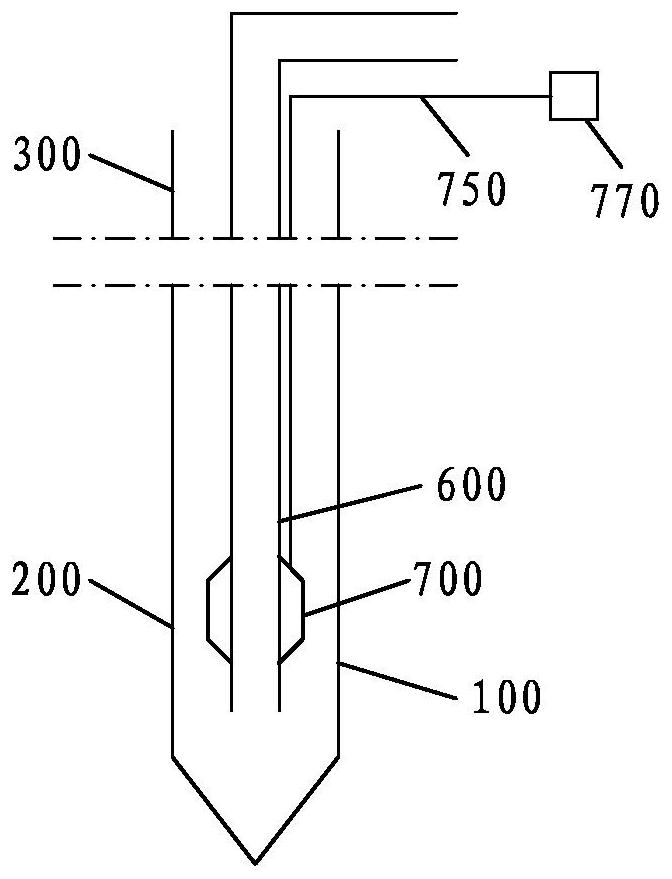

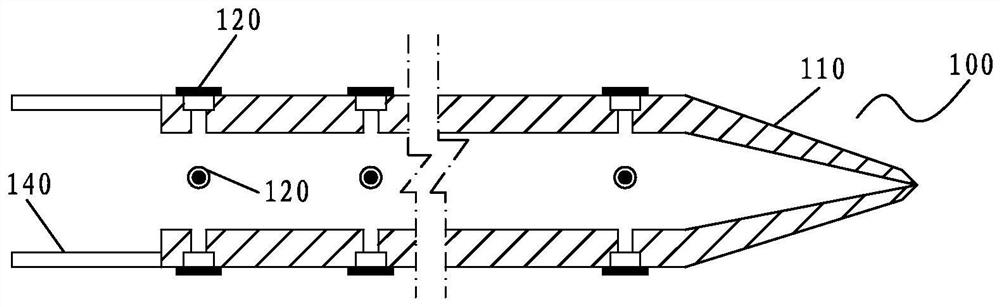

[0046] In step S2 , the type I cuff tube 100 , several type II cuff tubes 200 and several type III cuff tubes 300 are provided.

[0047] In step S3, the Type I sleeve valve tube 100 is lowered into the end of the borehole by its own weight, the Type II sleeve valve tube 200 is sequentially lowered into the designed grouting section of the borehole by its own weight, and the Type III sleeve valve tube 200 is sequentially lowered by its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com